High-voltage pulse modular water treatment power supply and control method thereof

A high-voltage pulse, modular technology, applied in the field of converters, can solve the problems of high device selection requirements, lack of isolation function, boost voltage stress and charging current peak value, etc., to achieve simple control methods, low voltage stress, The effect of small charging current peak

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with embodiment the present invention is described in further detail:

[0030] In this embodiment, under the environment of MATLAB / Simulink2019, the high-voltage pulse modular water treatment power supply proposed by the present invention is simulated, where N=3, that is, six SM units are used.

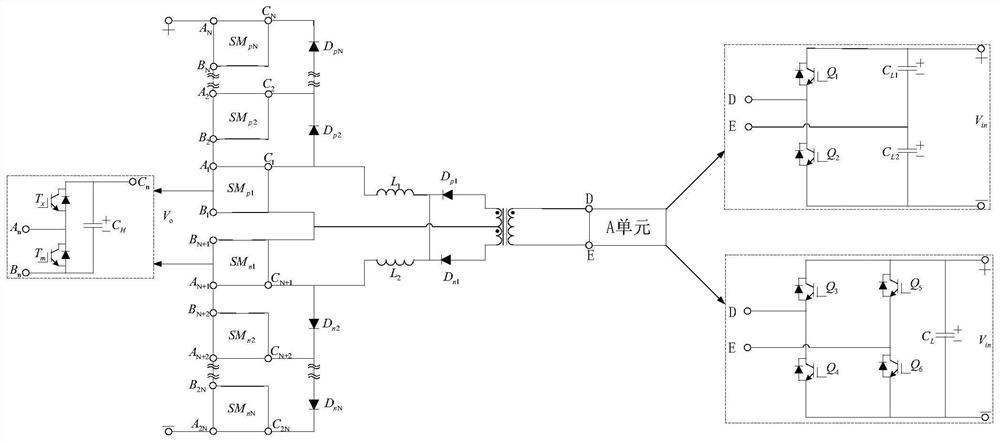

[0031] according to figure 1 As shown, a high-voltage pulse modularized water treatment power supply of the present invention includes: unit A, transformer, first to second N diodes, first filter, second filter, first to second N SM units, unit A has There are two forms of half-bridge module and full-bridge module, and the SM unit is a half-bridge MMC (Modular Multilevel Converter) module.

[0032] Such as figure 1 As shown, the present invention provides a high-voltage pulse modular water treatment power converter, the converter includes an A unit, a transformer, 2N diodes, two filters, and 2N SM units;

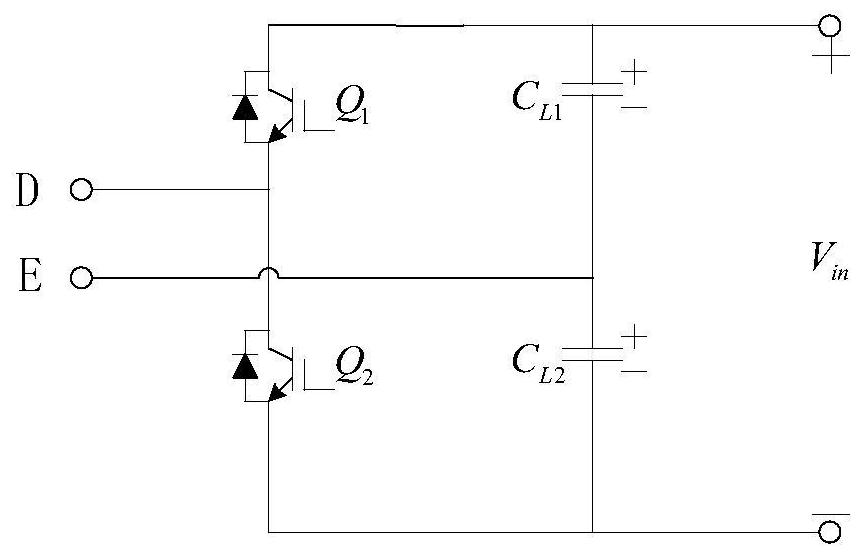

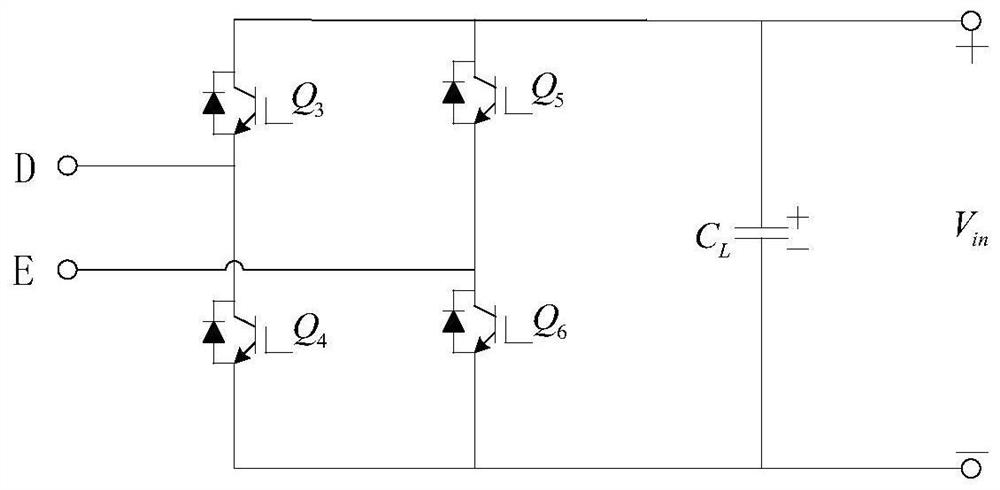

[0033] A unit has two forms, respectively as f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com