Rear axle housing assembly housing inner cavity trimming device

A technology of housing inner cavity and trimming device, which is applied in the field of mechanical processing and manufacturing, and can solve problems such as low operating efficiency and potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

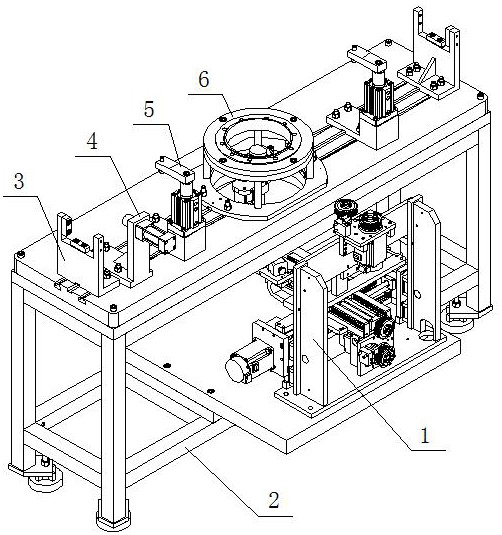

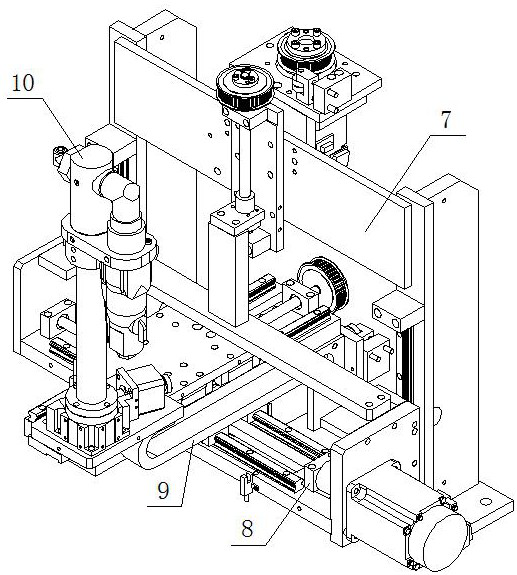

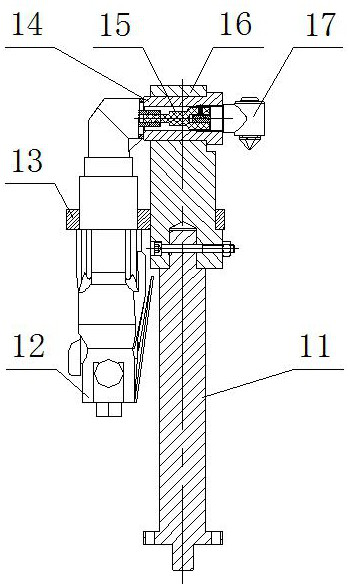

[0029] according to Figure 1-13 The specific structure of the present invention will be described in detail. The trimming device for the inner cavity of the rear axle housing assembly includes a frame 2, a positioning and clamping unit assembled on the frame 2 to fasten the rear axle housing assembly, a trimming unit 1 and a corresponding control circuit pre-edited according to common procedures. The frame 2 adopts a frame structure, the upper mounting plate is provided with key slots and T-shaped slots, the lower mounting plate is provided with pin holes and threaded holes, and the bottom is provided with adjustment shims. For safe operation, the outer periphery of frame 2 can be installed Fenders.

[0030] The positioning and clamping unit assembled on the upper floor mounting plate of the frame 2 is composed of side positioning plates 3, side pushing cylinders 4, rotating telescopic cylinders 5 and hollow positioning platforms 6 and the like. Wherein the hollow positioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com