Biological recognition chip surface coating treatment method

A technology of surface coating and biometric identification, which is applied in the post-processing of printing, the printing and printing of special varieties of printed matter, and can solve the problems of environmental impact of coatings, waste of raw materials, and large resource consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

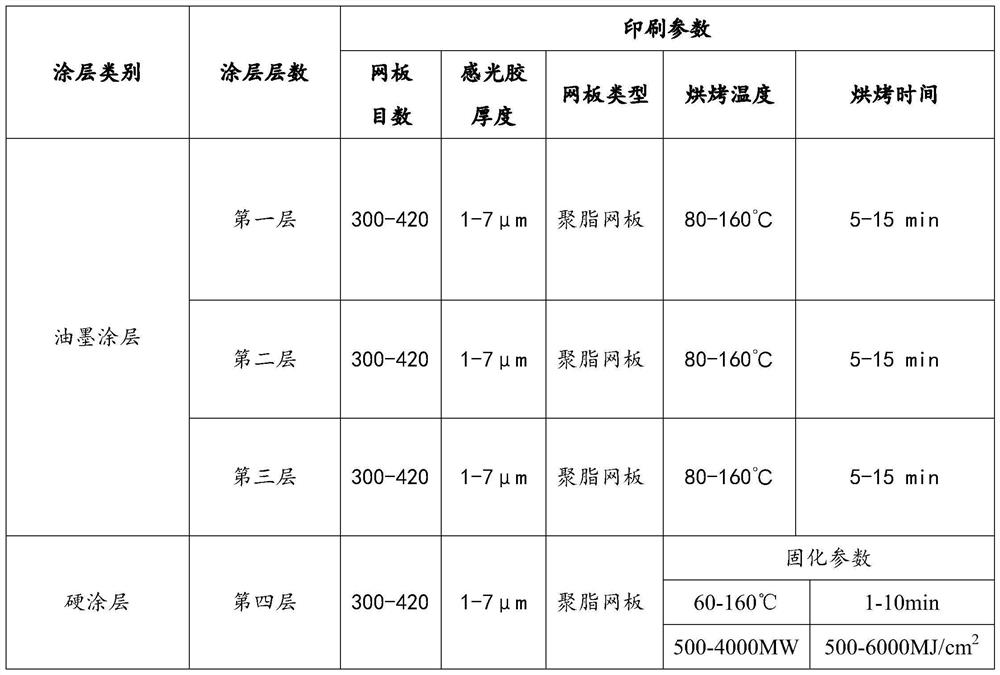

[0032] Step 1: Stencil Design

[0033] The outer diameter of the stencil is designed according to the size of the semiconductor chip. The stencil is made of a polyester stencil, and the mesh of the stencil is 300 mesh, and the thickness of the photosensitive adhesive on the stencil is designed to be 3 μm.

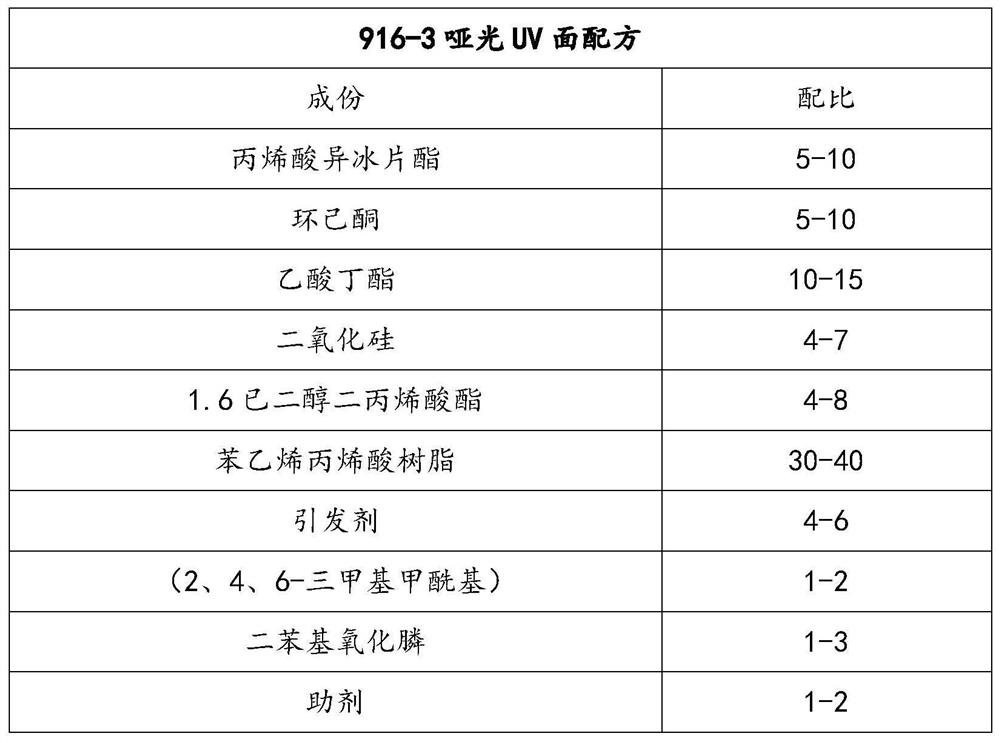

[0034] Step 2: Vehicle Design

[0035] Synchronously design the carrier for placing the chip into the same shape as the chip

[0036] The third step: scraper hardness setting

[0037] The scraper hardness of the silk screen is set to 75;

[0038] Step 4: Coating Printing

[0039] The surface of the semiconductor chip is printed with 4 layers of coating. The first layer is baked in a tunnel furnace at a temperature of 160°C for 15 minutes. The second layer is baked in a tunnel furnace at a temperature of 160°C. The baking time is 15 minutes, the third layer is baked in a tunnel oven, the baking temperature is 160°C, and the baking time is 15 minutes, the fourth layer is ...

example 2

[0041] Step 1: Stencil Design

[0042] The outer diameter of the stencil is designed according to the size of the semiconductor chip. The stencil is made of a polyester stencil, and the mesh of the stencil is 350 mesh, and the thickness of the photosensitive adhesive on the stencil is designed to be 5 μm.

[0043] Step 2: Vehicle Design

[0044] Synchronously design the carrier for placing the chip into the same shape as the chip

[0045] The third step: scraper hardness setting

[0046] The scraper hardness of the silk screen is set to 75;

[0047] Step 4: Coating Printing

[0048] The surface of the semiconductor chip is printed with 4 layers of coating. The first layer is baked in a tunnel furnace at a temperature of 160°C for 10 minutes. The second layer is baked in a tunnel furnace at a temperature of 160°C. The baking time is 10 minutes, the third layer is baked in a tunnel oven, the baking temperature is 160°C, and the baking time is 10 minutes, the fourth layer is ...

example 3

[0050] Step 1: Stencil Design

[0051] Design the outer diameter of the stencil according to the size of the semiconductor chip. The stencil is made of polyester stencil, and the mesh number of the stencil is 400 mesh, and the thickness of the photosensitive adhesive on the stencil is designed to be 6 μm.

[0052] Step 2: Vehicle Design

[0053] Synchronously design the carrier for placing the chip into the same shape as the chip

[0054] The third step: scraper hardness setting

[0055] The scraper hardness of the silk screen is set to 75;

[0056] Step 4: Coating Printing

[0057]The surface of the semiconductor chip is printed with 4 layers of coating. The first layer is baked in a tunnel furnace at a temperature of 160°C for 5 minutes. The second layer is baked in a tunnel furnace at a temperature of 160°C. The baking time is 5 minutes, the third layer is baked in a tunnel oven, the baking temperature is 160°C, and the baking time is 5 minutes, the fourth layer is bake...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com