Multi-stage cellulose raw material refining device capable of controlling feeding

A technology for cellulose and raw materials, which is applied in the field of multi-stage refinement devices for cellulose raw materials, which can solve problems such as difficult cleaning, low degree of refinement, and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

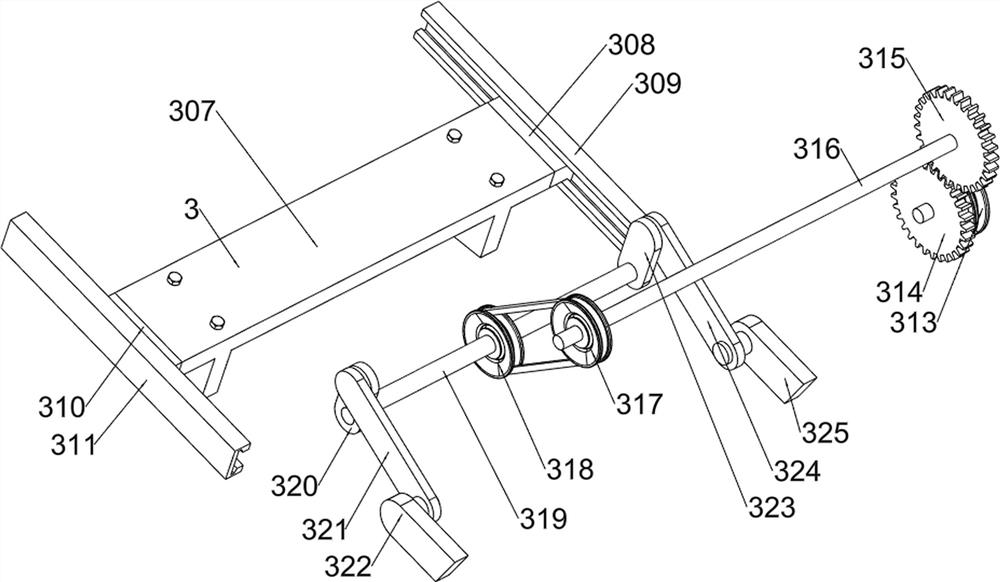

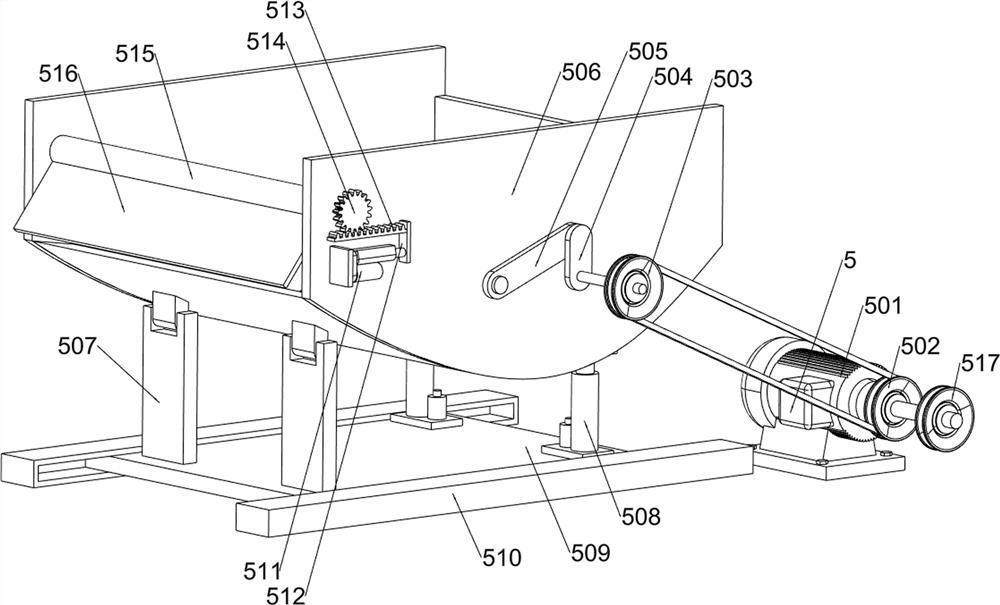

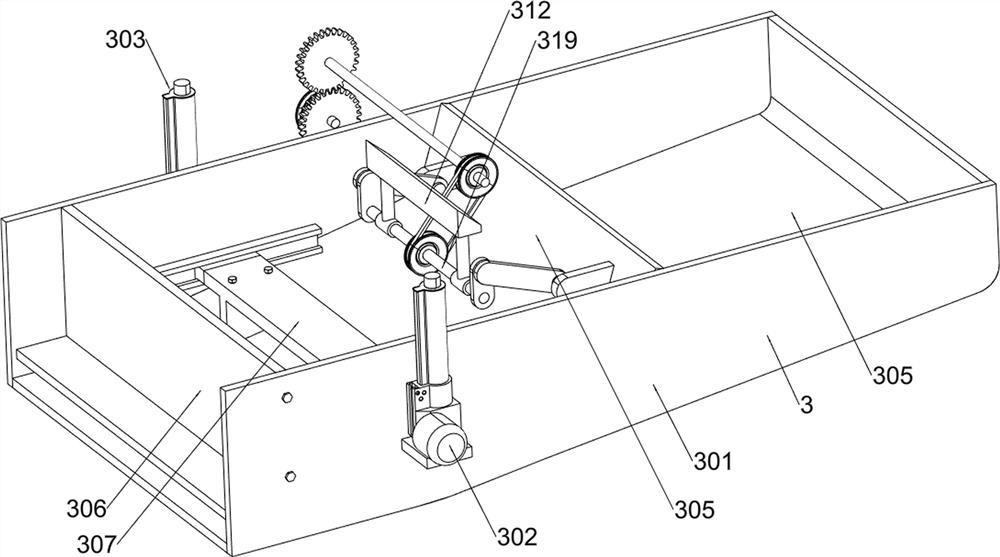

[0091] A multi-stage refinement device for cellulose raw materials with controllable feeding, such as Figure 1-10 As shown, it includes a support frame 1, a control panel 2, a first-level loose system 3, a second-level loose system 4, and an adjustable feeding system 5; the support frame 1 is used for supporting devices; Connection; the first-level loose system 3 is connected with the support frame 1; the second-level loose system 4 is connected with the support frame 1, and the second-level loose system 4 is connected with the first-level loose system 3; the adjustable feeding system 5 is connected with the support frame The body 1 is connected, and the adjustable feeding system 5 is connected with the primary loose system 3.

[0092] Working principle: Before using this device, first install the device at the feed port of the cellulose acetate processing equipment, prepare a sufficient amount of cotton pulp as raw material for cellulose acetate processing and place it near ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com