Combined bent cap suitable for bridge deck continuous structure, bridge and construction technology

A technology of covering beams and structures, applied in bridges, bridge parts, bridge materials, etc., can solve problems such as poor bridge deck durability, high construction requirements, and impact on driving comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

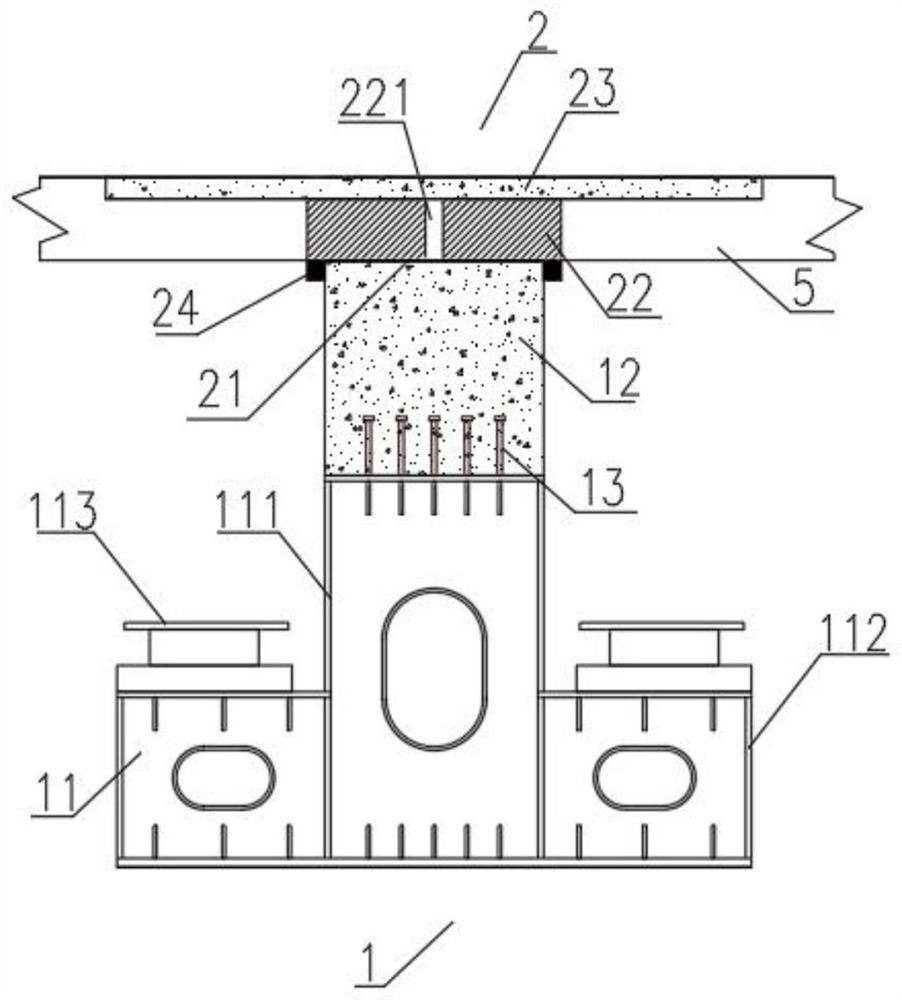

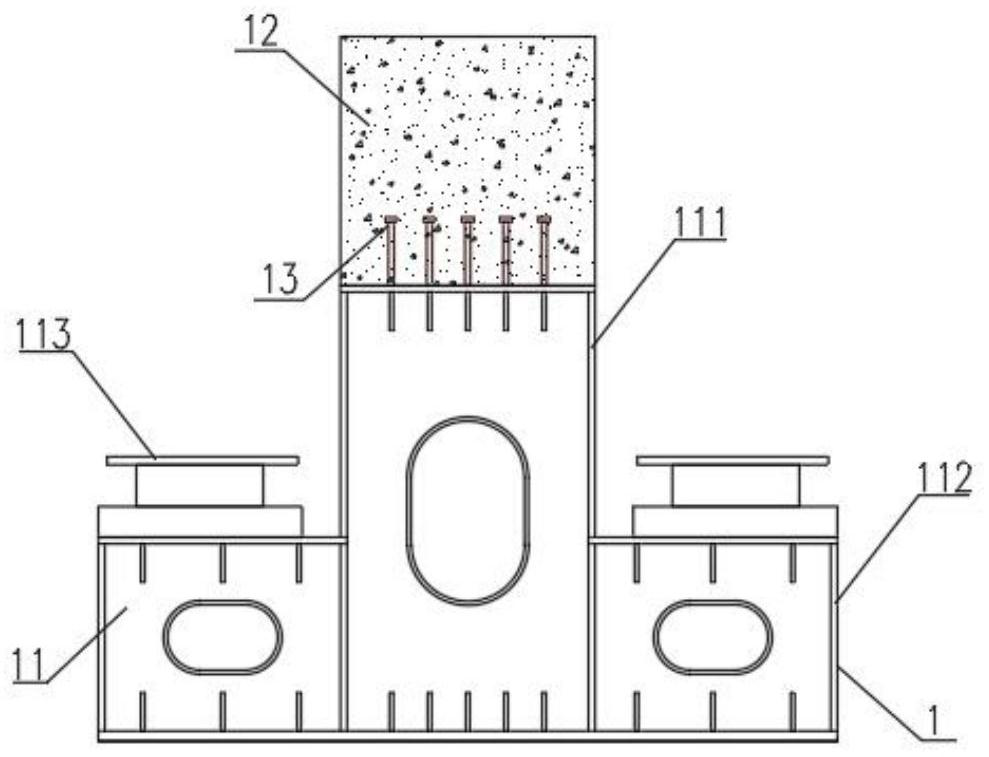

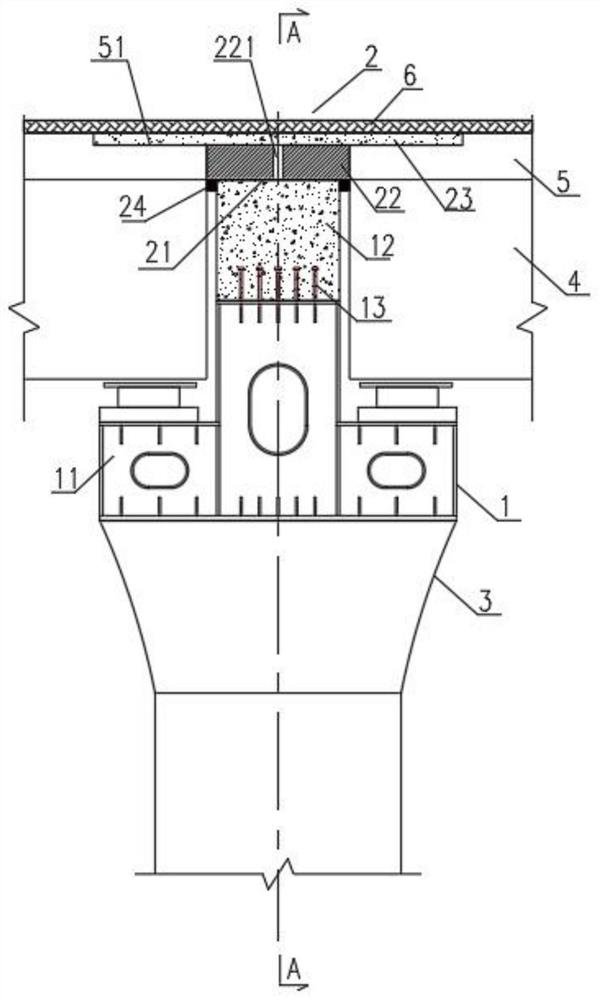

[0043] Such as Figure 1~2 As shown, the composite cover beam suitable for the continuous structure of the bridge deck in this embodiment includes a steel-concrete composite cover beam 1 and a bridge deck continuous structure 2 arranged on the upper end of the steel-concrete composite cover beam 1. The steel-concrete composite cover beam 1 includes The steel girder 11 and the concrete block 12 arranged on the top of the steel girder 11, the bridge deck continuous structure 2 includes an adaptable deformable backing plate 21 arranged on the top of the concrete block 12, a first post-casting on the top of the adaptable deformable backing plate 21 Concrete 22, the second post-cast concrete 23 arranged on the top of the first post-cast concrete 22, the middle of the first post-cast concrete 22 is provided with a vertical gap 221 extending along the bridge deck width direction, the first post-cast Both the concrete 22 and the second post-cast concrete 23 are fixedly connected to th...

Embodiment 2

[0053] Such as Figure 1~4 As shown, the combined bridge in the present embodiment includes pier columns 3, prefabricated main girders 4, bridge decks 5 arranged on the top of prefabricated main girders 4, fixed on pier columns 3 as described in Embodiment 1 and is applicable to The composite cover girder with continuous structure of the bridge deck, the prefabricated main girder 4 is erected on both sides of the steel-concrete composite cover beam 1 , specifically on the beam body support 113 . There is a gap between the prefabricated main girder 4 and the steel-concrete composite cover girder 1 , and the top surface of the concrete block 12 is flush with the bottom surface of the bridge deck 5 . And generally, the inner side walls of the prefabricated girder 4 and the bridge deck 5 are flush.

[0054] The composite bridge in this embodiment adopts the composite cover girder in Embodiment 1, and the bridge structure bears reasonable force, so that the formed bridge deck has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com