Anchoring system and method for earthen site reinforcement

An anchoring system and technology for earthen ruins, applied in the repair of foundation structures, sheet pile walls, buildings, etc. Pressure cracking and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

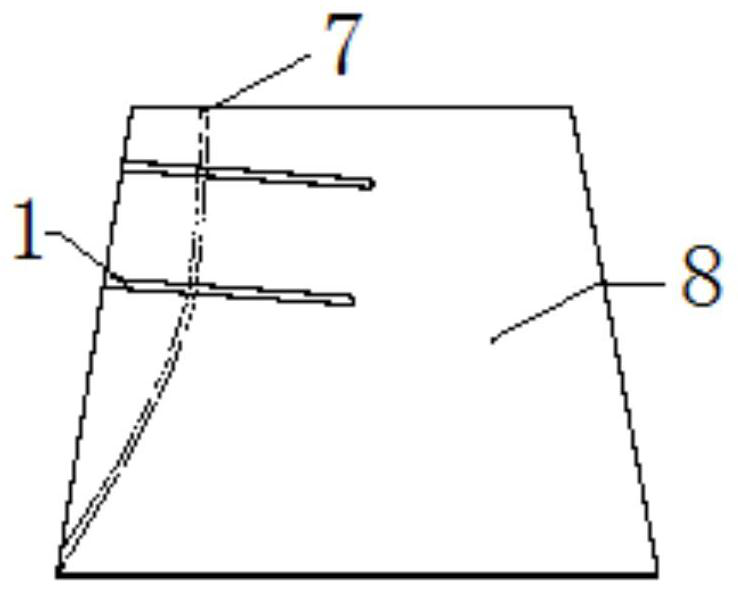

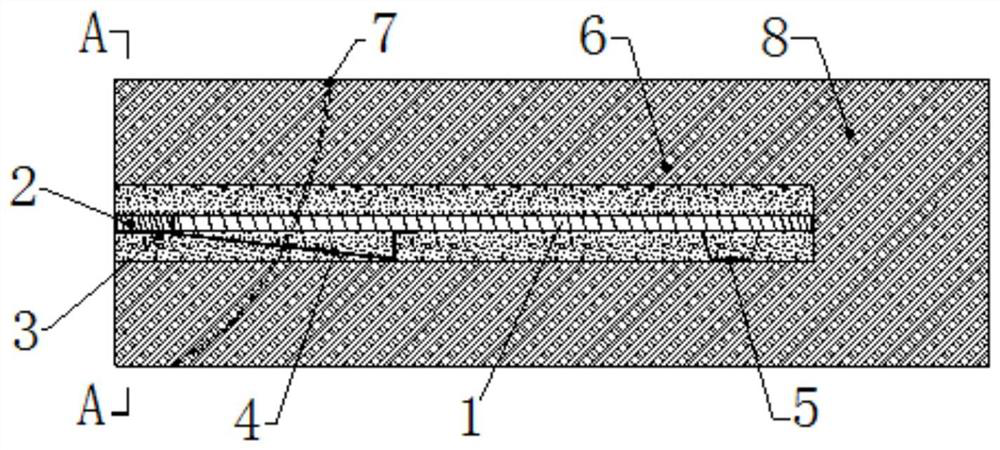

[0052] as attached Figure 1-6 As shown, taking a certain earthen ruins as an example, the depth of the potential slip surface of the earthen ruins is between 100-600mm, and a small potential sliding body is formed on the earthen ruins; The reinforced anchoring system includes a fiber composite anchor rod 1 and a grouting body 6 .

[0053] The fiber composite anchor 1 is set in the anchor hole on the soil site to be reinforced, and the fiber composite anchor 1 is arranged in the soil site to be reinforced according to the preset spacing, length and angle; according to the soil mechanical properties of the soil site to be reinforced, the prepared For the grouting body material, use a grouting machine to pour the grouting body material into the anchor hole, and form the grouting body 6 in the gap between the fiber composite anchor rod 1 and the anchor hole.

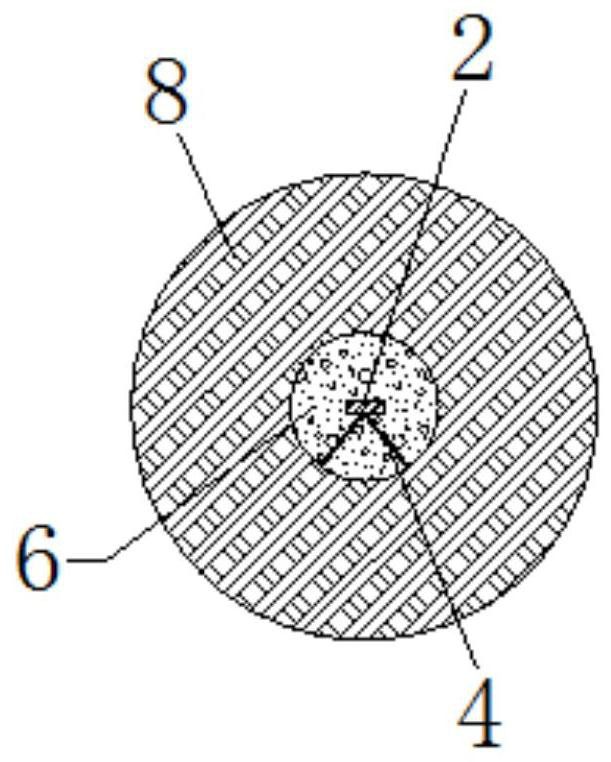

[0054] The fiber composite anchor 1 includes geotechnical fiber filament 2, wrapping fiber 3, first stressed support 4 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com