Surface point vibration type vibrating rod

A technology of vibrating rods and surface points, which is applied in the fields of construction, building structure, and building materials, and can solve problems such as manual cleaning and removal, affecting construction efficiency, and easy adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

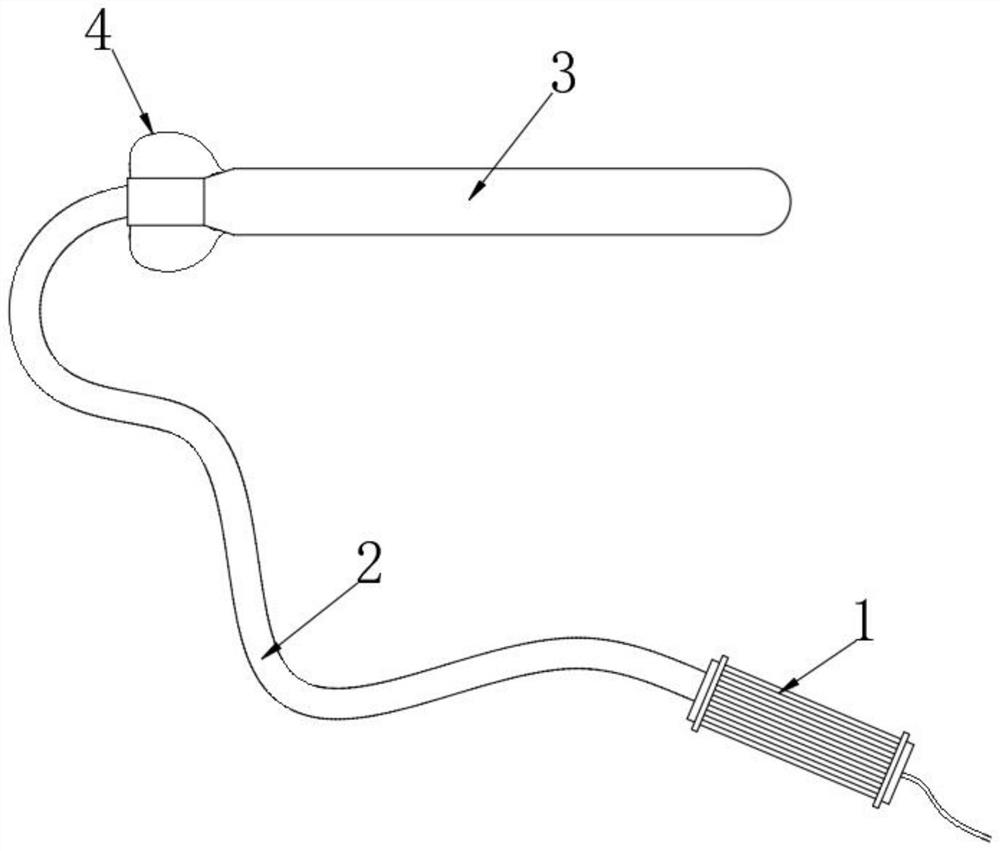

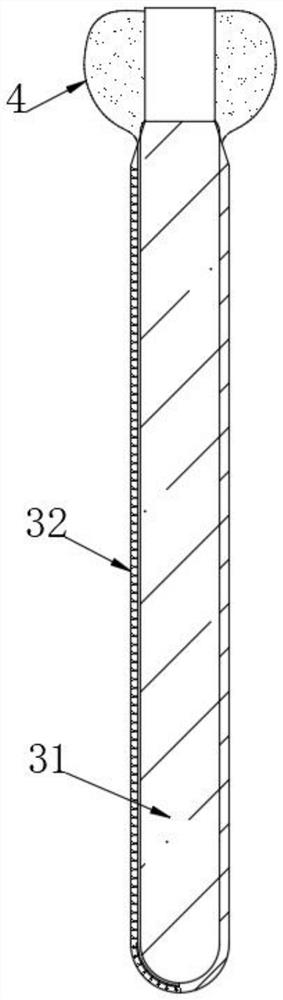

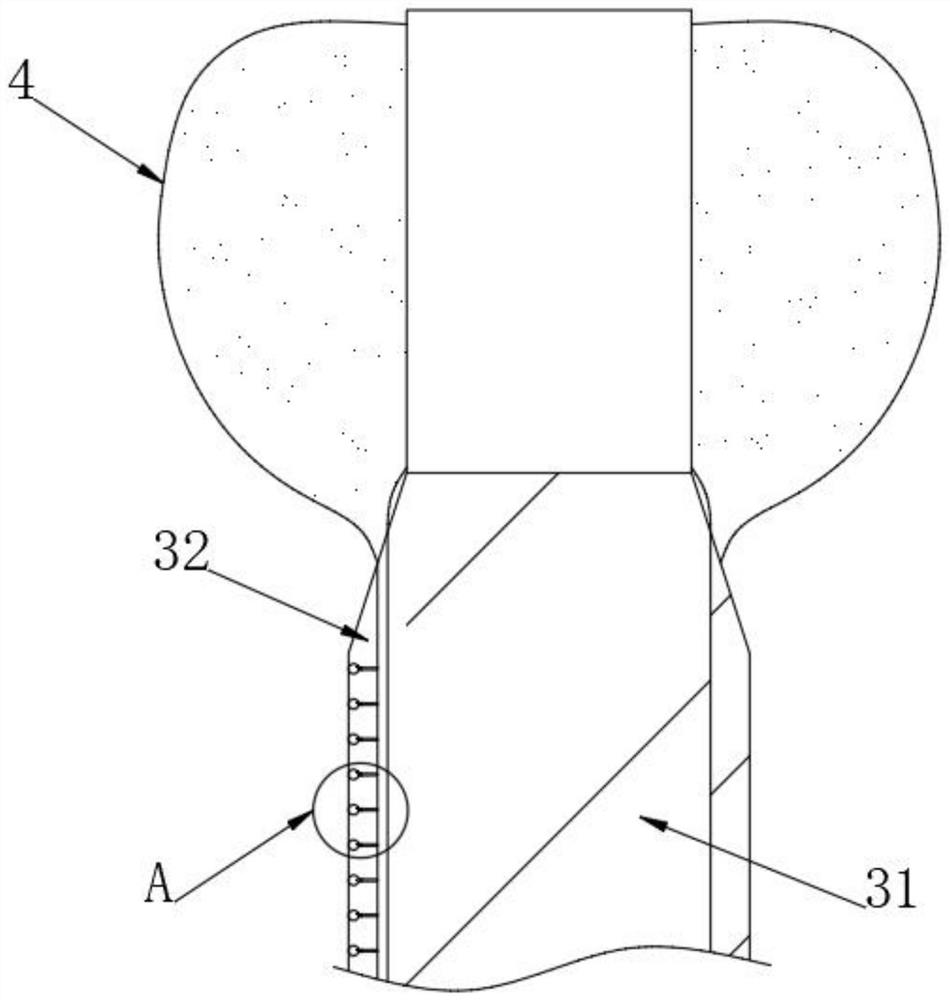

[0043] see figure 1 , a surface point vibration vibrator, including a driver 1, a vibrating end 3 and a hose 2 connected between the driver 1 and the vibrating end 3, and the outer end of the connection between the vibrating end 3 and the hose 2 is fixedly connected There is a drum pressure ring 4. The drum pressure ring 4 is made of elastic sealing material, and the drum pressure ring 4 is filled with compressed gas. The compressed gas is a compressed non-toxic gas, preferably air, and the compression ratio of the air is not more than 1.2 times. If the compression ratio is too large, it is easy to cause the air shock ball 71 to break away from the mouth of the main gas-gathering hole 62 when the pressure drum ring 4 is not pressed, so that when the pressure drum ring 4 is pressed, the internal compressed gas passes through the main gas-gathering hole 62 The rear part directly enters into the ball-shaped groove 61, resulting in a small driving force on the air shock ball 71, s...

Embodiment 2

[0048] see Figure 7 , the air shock cavity includes a gas-gathering auxiliary hole 81 communicating with the U-shaped gas-dispersing chamber 5 and a hemispherical striking groove 82 communicating with the gas-gathering auxiliary hole 81, and the hemispherical striking groove 82 is excavated near the inner bottom of the mouth of the gas-gathering auxiliary hole 81 There is a spherical groove, and the spherical groove matches the air-shock ball 71, so that the air-shock ball 71 can smoothly return to the spherical groove after hitting the outer micro-shock hard shell 32, so that it just blocks the gas-gathering auxiliary hole 81 The mouth part effectively ensures that the air shock hitting ball 71 can receive a relatively large impact force from the inert gas, effectively guarantees the impact force of the external micro-shock hard shell 32, and makes the multi-point micro-vibration effect on the surface of the external micro-shock hard shell 32 Better yet, the cross section of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com