Pulse tube refrigerator with low-temperature cavity structure

A pulse tube refrigerator and cavity structure technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of large regenerator loss, low refrigeration efficiency, and large acoustic power at the inlet of the inertial tube.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

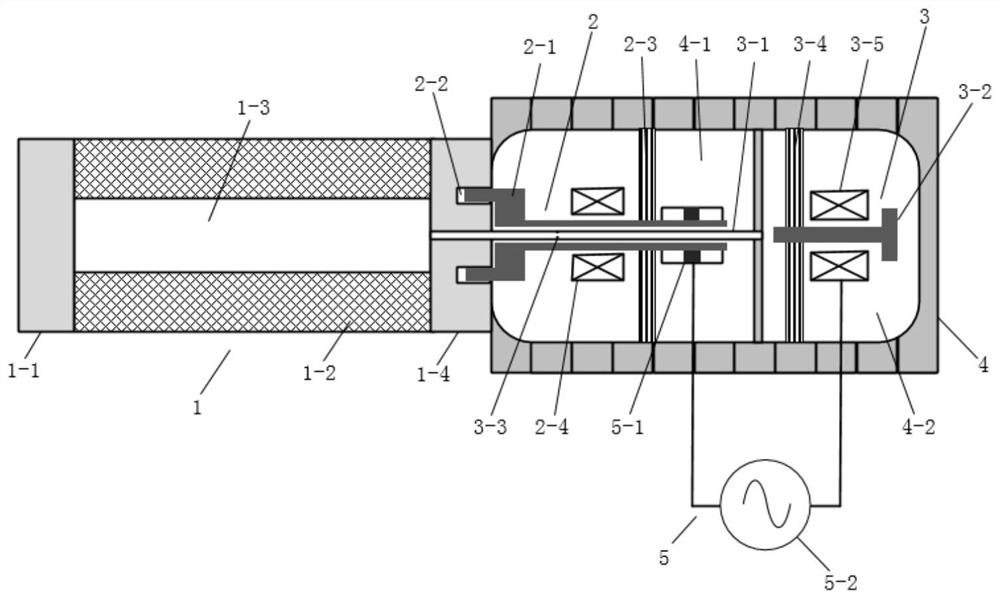

[0019] combine figure 1 As shown, this embodiment provides a pulse tube refrigerator with a low-temperature cavity structure, including a pulse tube refrigerator cold finger 1, an annular drive mechanism 2, a vibration-reduction phase-modulation mechanism 3, a low-temperature cavity, and a data acquisition and control mechanism 5 . Among them, the cold finger 1 of the pulse tube refrigerator includes a cold end 1-1, a regenerator 1-2, a pulse tube 1-3 and a hot end 1-4, and the annular drive mechanism 2 includes an annular piston 2-1 and a compression chamber 2-2 , an annular piston support mechanism 2-3 and an annular piston drive mechanism 2-4, the vibration damping phase modulation mechanism 3 includes a linear low temperature inertia tube 3-1, a vibration damping phase modulation piston 3-2, an orifice valve 3-3, a vibration damping The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com