Low-temperature turbine refrigerator

A turbo refrigerator and low-temperature technology, applied in refrigerators, compressors using turbines, refrigeration and liquefaction, etc., can solve problems such as low integration, large application limitations, and large irreversible losses in throttling refrigeration, and achieve energy The effect of high density, small irreversible loss and good application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. Obviously, the described embodiments It is a part of embodiments of the present invention, but not all embodiments.

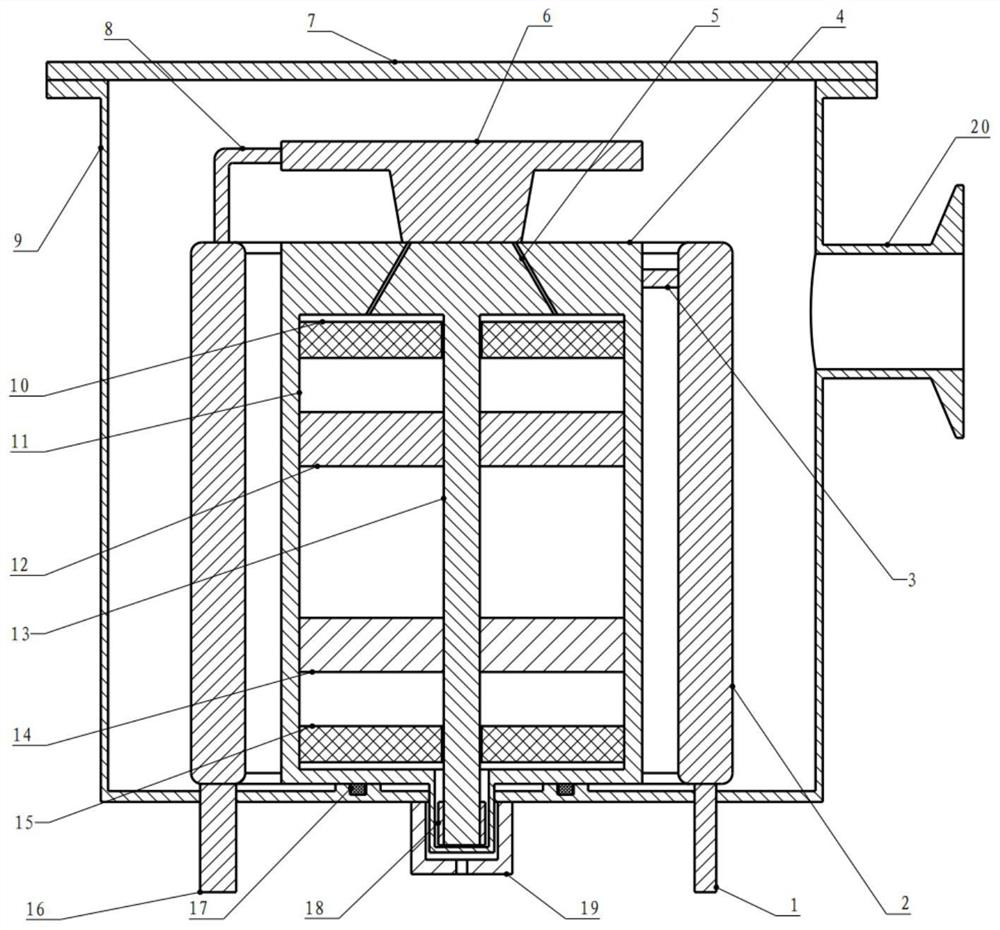

[0024] combine figure 1 As shown, the air flotation turbine refrigeration system for the environmental test equipment of the present invention consists of a high-pressure normal-temperature intake pipe 1, an annular regenerative heat exchanger 2, a high-pressure low-temperature connecting pipe 3, a volute nozzle 4, an expansion turbine 5, and a cold-end heat exchanger 6 , vacuum dewar cover 7, low-pressure low-temperature connecting pipe 8, vacuum dewar 9, bearing chamber cold end heat insulation layer 10, bearing chamber 11, upper bearing 12, main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com