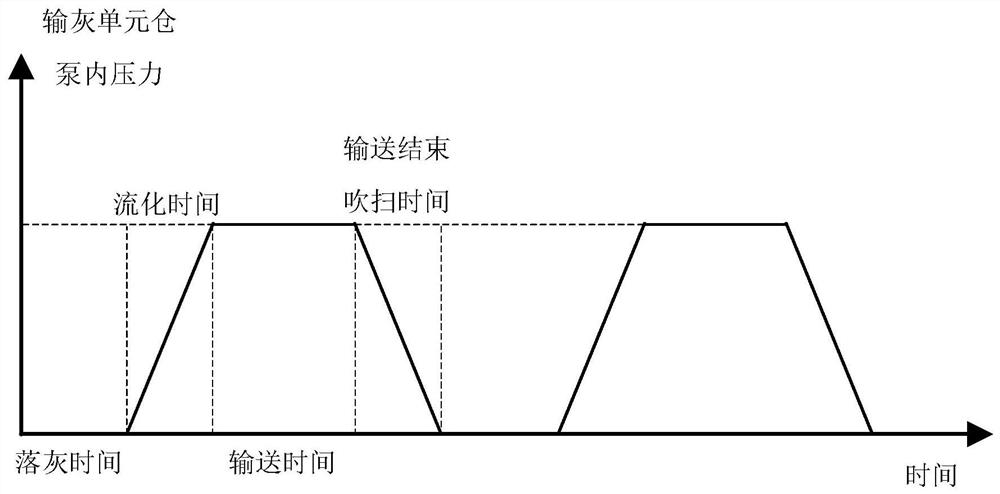

Coal-fired power plant ash conveying system dynamic energy-saving control method based on actual coal quality parameters

A technology for coal-fired power plants and system dynamics, applied in electrical program control, comprehensive factory control, program control, etc., can solve the problems of ash blocking and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

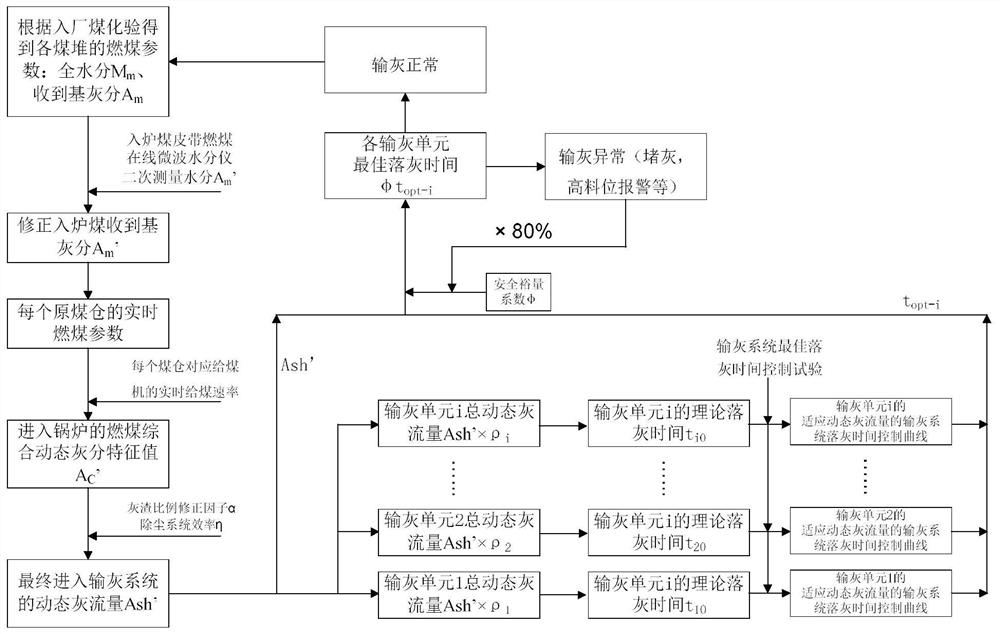

[0028] step one:

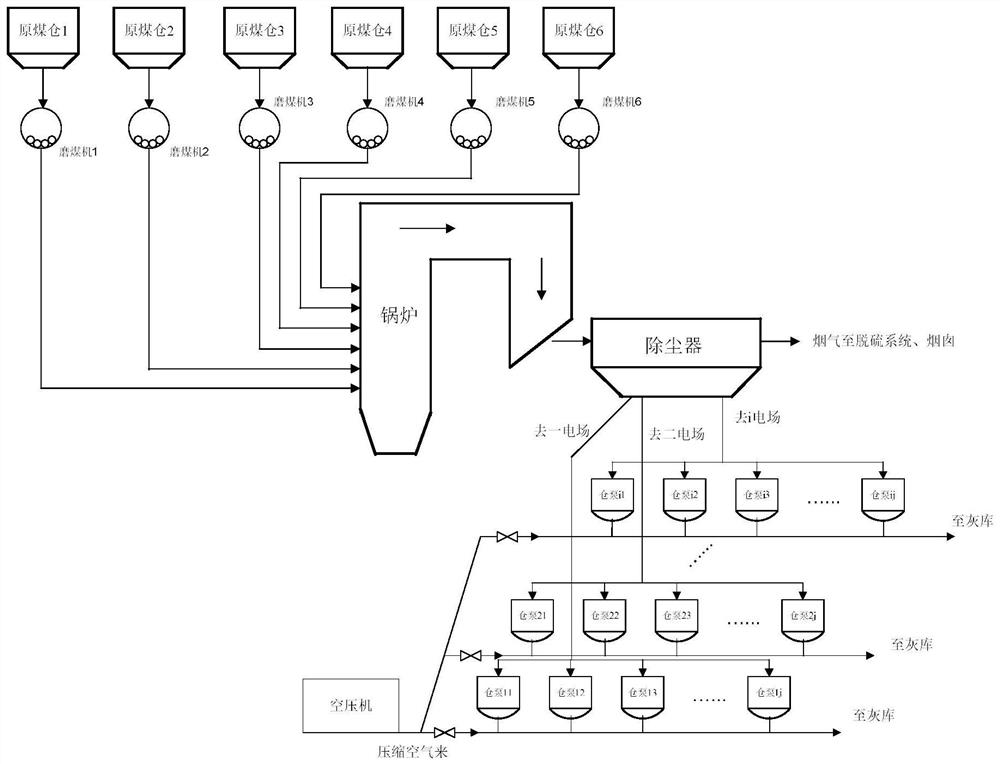

[0029] Establish a coal-fired real-time coal quality parameter model for the ash conveying system (see the system diagram for details figure 2 ):

[0030] (1) After the coal enters the coal yard, it is piled up according to the type of coal, and the coal parameters of the coal pile are obtained from the incoming coal test:

[0031] Total Moisture M m ;Received base ash A m , the subscript m is the coal pile number

[0032] (2) Introduce a coal-fired online microwave moisture meter on the furnace coal belt, and conduct a secondary measurement of the total moisture of the coal entering each coal bunker: M′ m , and use it to correct the received base ash: A′ m .

[0033]

[0034] (3) According to the real-time coal feeding rate G of the coal feeder corresponding to each coal bunker 1 ~G 6 , the unit is t / h, and the real-time coal-fired parameters entering each coal bunker are obtained from (2), and then the comprehensive dynamic ash characteristic v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com