Biomacromolecular repairing agent for lead-acid storage battery and preparation method of biomacromolecular repairing agent

A biomacromolecule, lead-acid battery technology, applied in the direction of lead-acid battery, secondary battery repair/maintenance, secondary battery, etc., can solve problems such as uneven repair efficiency and success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

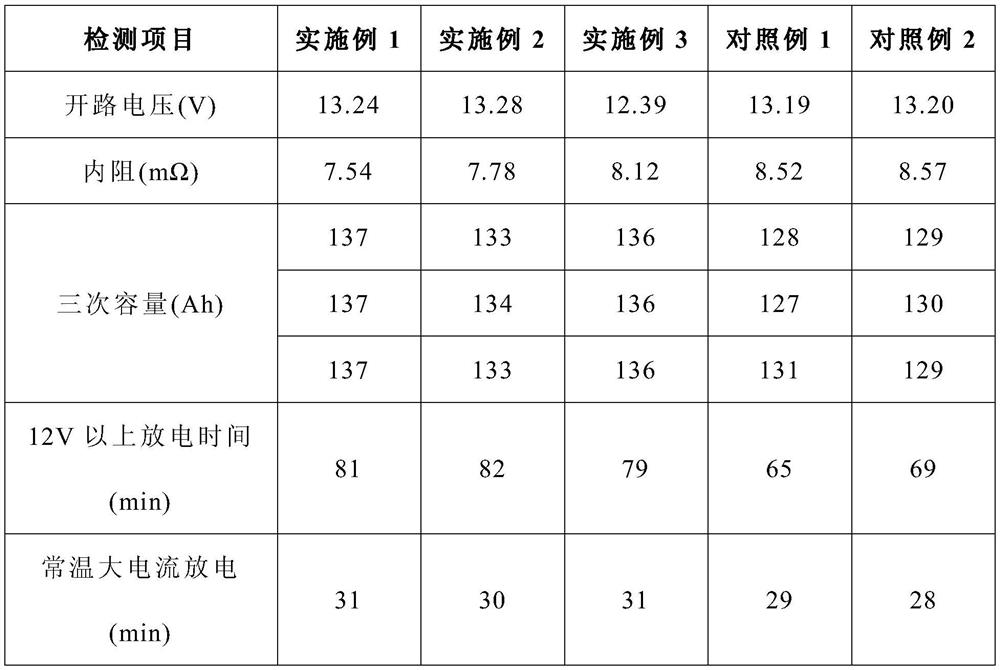

Embodiment 1

[0033] A biomacromolecule restoration agent for lead-acid batteries, comprising the following raw materials in parts by weight: 6 parts of γ-hydroxybutyric acid, 7 parts of acetic acid, 7 parts of γ-PGA, 4 parts of N-acetylgluconic acid, and 6 parts of Lunasin peptide 18 parts of ST peptide, 5 parts of β-hydroxy-α-aminobutyric acid, 7 parts of L-2-amino-3-hydroxypropionic acid, 20 parts of distilled water, and 20 parts of sulfuric acid.

[0034] Its preparation method comprises the following steps:

[0035] S1. Take 6 parts of γ-hydroxybutyric acid and add it to 10 parts of distilled water, stir, and after mixing evenly, add 7 parts of acetic acid and 7 parts of γ-PGA in sequence, and continue stirring for 1.5 hours at room temperature to obtain a mixed solution A;

[0036] S2. Take 4 parts of N-acetylgluconic acid and 6 parts of Lunasin peptide and add them together to 10 parts of distilled water, stir at room temperature for 35 minutes, and obtain the mixed solution B after ...

Embodiment 2

[0039] A biomacromolecule restoration agent for lead-acid batteries, comprising the following raw materials in parts by weight: 3 parts of γ-hydroxybutyric acid, 6 parts of acetic acid, 6 parts of γ-PGA, 3 parts of N-acetylgluconic acid, and 5 parts of Lunasin peptide 24 parts of ST peptide, 9 parts of β-hydroxy-α-aminobutyric acid, 4 parts of L-2-amino-3-hydroxypropionic acid, 20 parts of distilled water, and 20 parts of sulfuric acid.

[0040] Its preparation method comprises the following steps:

[0041] S1. Take 3 parts of γ-hydroxybutyric acid and add it to 10 parts of distilled water, stir, and after mixing evenly, add 6 parts of acetic acid and 6 parts of γ-PGA in sequence, and continue stirring for 1.5 hours at room temperature to obtain a mixed solution A;

[0042] S2. Take 3 parts of N-acetylgluconic acid and 5 parts of Lunasin peptide and add them to 10 parts of distilled water, stir at room temperature for 30 minutes, and obtain the mixed solution B after dispersin...

Embodiment 3

[0045] A biomacromolecule restoration agent for lead-acid batteries, comprising the following raw materials in parts by weight: 4 parts of γ-hydroxybutyric acid, 4 parts of acetic acid, 10 parts of γ-PGA, 3 parts of N-acetylgluconic acid, and 6 parts of Lunasin peptide 20 parts of ST peptide, 6 parts of β-hydroxy-α-aminobutyric acid, 2 parts of L-2-amino-3-hydroxypropionic acid, 20 parts of distilled water, and 25 parts of sulfuric acid.

[0046] Its preparation method comprises the following steps:

[0047] S1. Take 4 parts of γ-hydroxybutyric acid and add it to 10 parts of distilled water, stir. After mixing evenly, add 4 parts of acetic acid and 10 parts of γ-PGA in sequence, and continue stirring for 1.5 hours at room temperature to obtain a mixed solution A;

[0048] S2. Add 3 parts of N-acetylgluconic acid and 6 parts of Lunasin peptide to 10 parts of distilled water, stir at room temperature for 30 minutes, and obtain mixed solution B after dispersing evenly;

[0049] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com