Black tea primary processing technology

A technology, black tea technology, applied in the field of black tea primary processing technology, can solve the problem of not being very good at terminating the enzymatic reaction and failing to achieve the expected effect, and achieve the effects of reducing the bitterness and astringency of tea soup, facilitating cell damage, and increasing the content of amino acids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

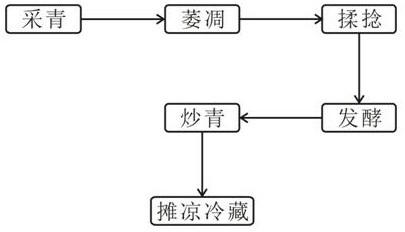

Image

Examples

Embodiment 1

[0025] The present embodiment provides a kind of black tea primary processing technology, comprises the following steps:

[0026] S0 green picking: pick fresh leaves with one bud and two leaves or one bud and three leaves, and do not harvest leaves with rain or dew. The picking time is between 10:00 am and 4:00 pm on sunny days;

[0027] S1 Withering: The picked and graded fresh leaves are naturally withered twice and once in the sun. The first natural withering time is 6.5 hours, then withered in the sun for 2.5 hours, and then the second natural withering is carried out for 1 hour to make the leaves soft. The leaves and stems are not easy to break, the tea fragrance is obvious, and the leaves are withered; the conditions for natural withering are temperature 20°C-25°C, relative humidity 60%-70%;

[0028] S2 kneading: put the withered leaves into a kneading machine for initial kneading-deblocking-re-kneading-deblocking and cooling, so that a small amount of tea juice overflow...

Embodiment 2

[0033] The present embodiment provides a kind of black tea primary processing technology, comprises the following steps:

[0034] S0 green picking: pick fresh leaves with one bud and two leaves or one bud and three leaves, and do not harvest leaves with rain or dew. The picking time is between 10:00 am and 4:00 pm on sunny days;

[0035] S1 Withering: The fresh leaves picked and graded are subjected to natural withering for two times and sunlight for one time successively. The first natural withering time is 8 hours, then withering in the sun for 2 hours, and then the second natural withering for 1 hour to make the leaves soft and tender. The stems are not easy to break, the tea fragrance is obvious, and the leaves are withered; the natural withering conditions are a temperature of 20°C-25°C and a relative humidity of 60%-70%;

[0036] S2 kneading: put the withered leaves into a kneading machine for initial kneading-deblocking-re-kneading-deblocking and cooling, so that a smal...

Embodiment 3

[0041] The present embodiment provides a kind of black tea primary processing technology, comprises the following steps:

[0042] S0 green picking: pick fresh leaves with one bud and two leaves or one bud and three leaves, and do not harvest leaves with rain or dew. The picking time is between 10:00 am and 4:00 pm on sunny days;

[0043] S1 Withering: The fresh leaves picked and graded are subjected to natural withering for two times and sunlight for one time successively. The first natural withering time is 6 hours, then withering in the sun for 3 hours, and then the second natural withering for 1 hour, so that the leaves are soft and tender. The stems are not easy to break, the tea fragrance is obvious, and the leaves are withered; the natural withering conditions are a temperature of 20°C-25°C and a relative humidity of 60%-70%;

[0044] S2 kneading: put the withered leaves into a kneading machine for initial kneading-deblocking-re-kneading-deblocking and cooling, so that a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com