Method for preparing fatty acid phytosterol ester employing catalysis of silicon dioxide

A technology of phytosterol esters and phytosterols, which is applied in the field of silica catalyzed preparation of fatty acid phytosterol esters to achieve the effects of reduced usage, high reactivity, and good color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

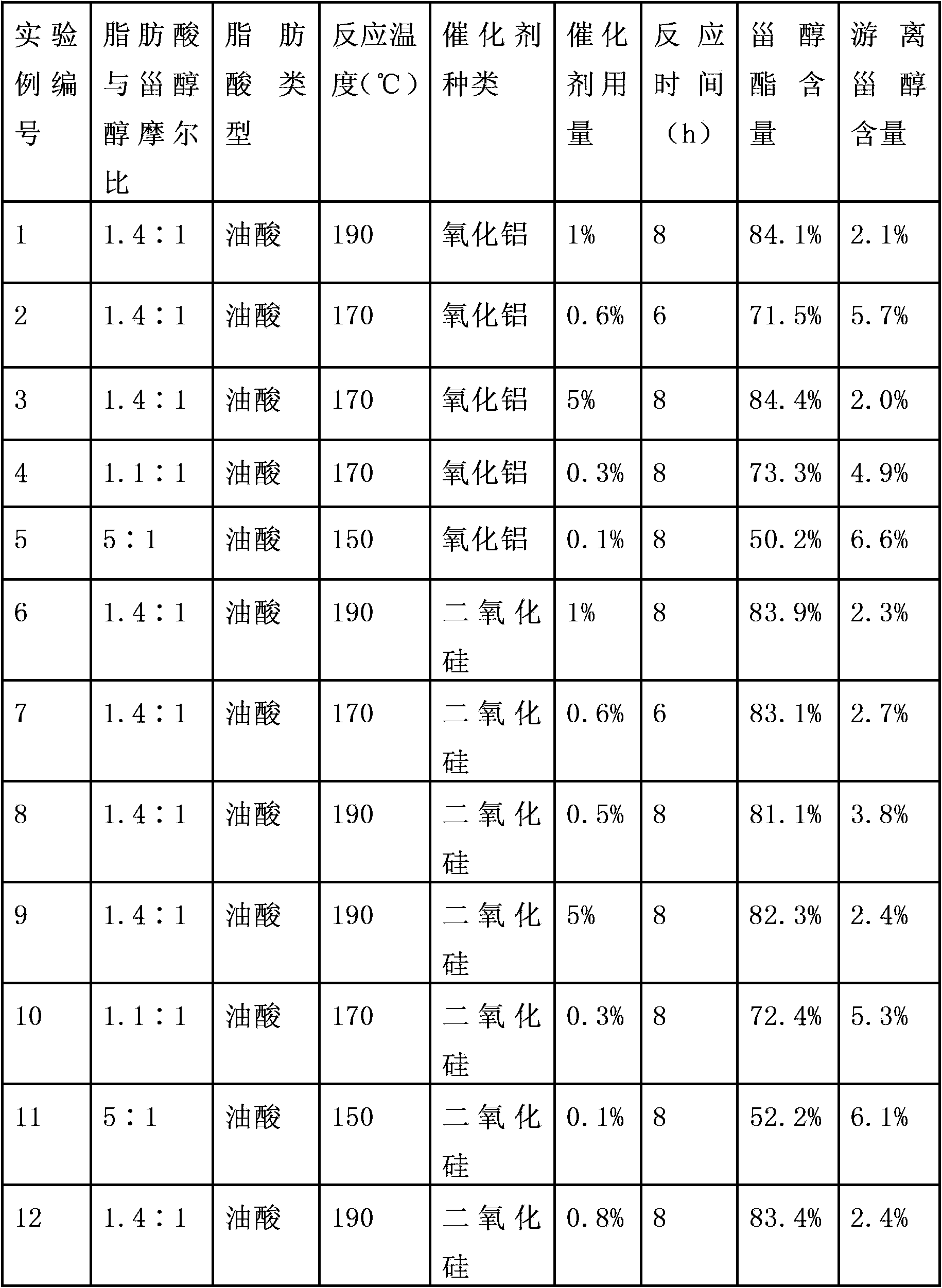

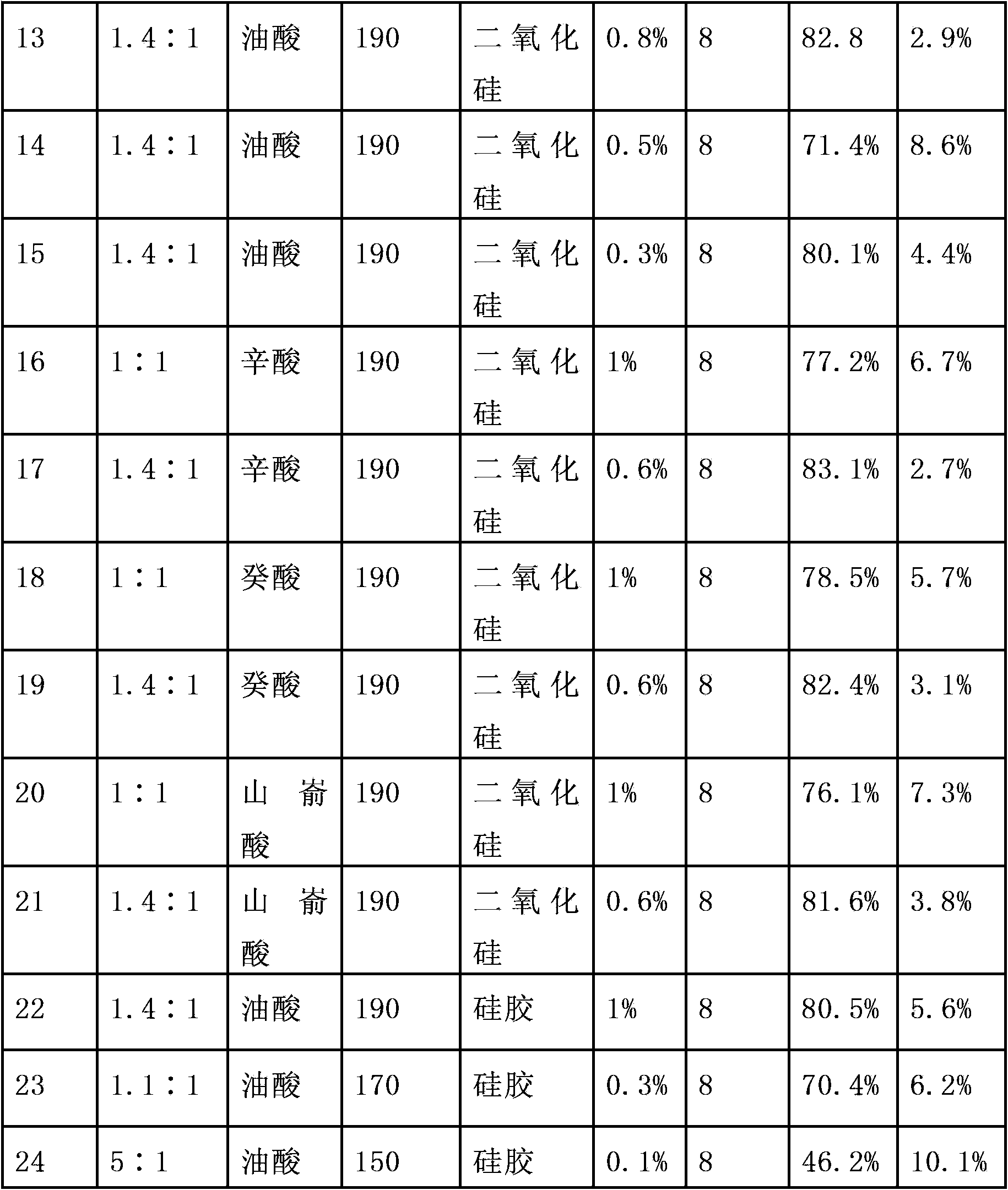

[0060] Example 1: Preparation of fatty acid phytosterol ester

[0061] The preparation method is as follows: Put fatty acids and phytosterols in a clean and dry three-necked flask according to the ratio in Table 1, and heat to 130°C until a homogeneous oily substance is formed, and then react under vacuum conditions according to the conditions shown in Table 1. , The vacuum pressure is below 4mBar.

[0062] Fatty acids are oleic acid, caprylic acid, capric acid, and behenic acid. Phytosterol is a mixture of 43.48%-sitosterol, 25.06% stigmasterol, 25.90% campesterol, and 1.01% rapeseed sterol (the mixture has a purity of 95.45%), catalyst It is alumina, silica, silica gel. The molar ratio of fatty acid to phytosterol, the amount of catalyst (weight percentage in the entire reaction system), the esterification temperature, and the reaction time are shown in Table 1. The entire reaction process is carried out under vacuum until the reaction is completed, and the degree of completion ...

Embodiment 2

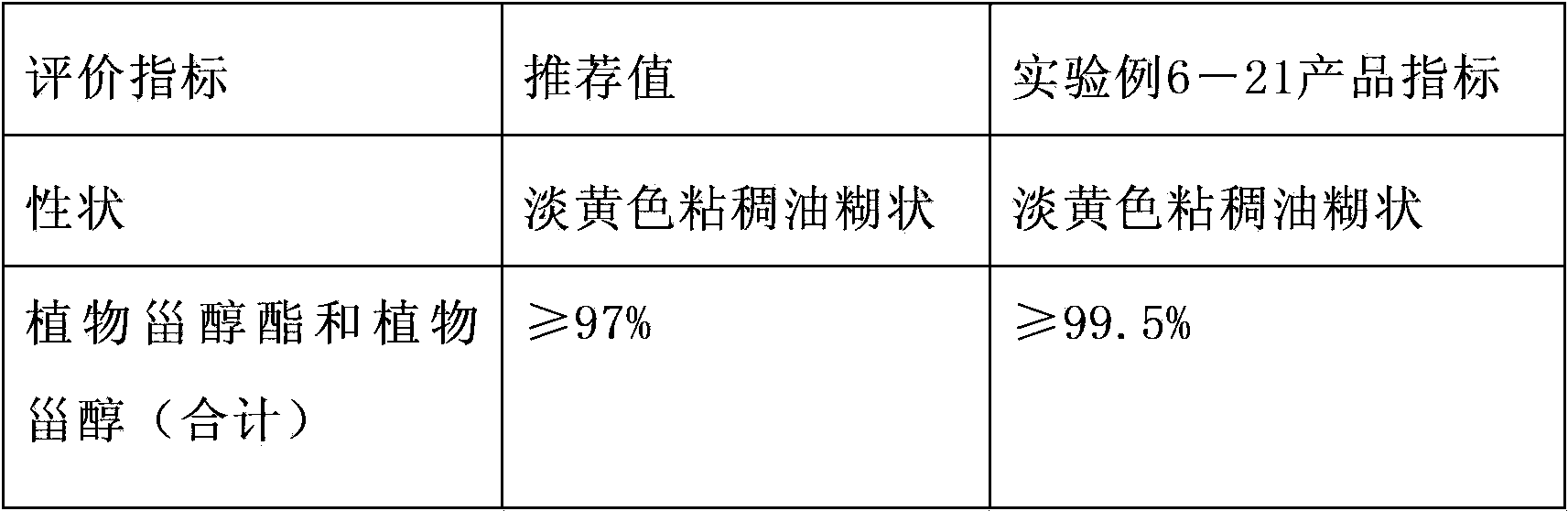

[0070] Example 2: Detection of element content of fatty acid phytosterol esters prepared under different reaction conditions

[0071] Table 2: Detection of element content of fatty acid phytosterol esters prepared under different reaction conditions

[0072] Experiment number

Detection of metal elements

Detection value

1-5

Al

251mg / kg-755mg / kg

6-21

Si

not detected

[0073] The detection of the element content adopts the ICP / AES method.

[0074] From the test results, it can be seen that when the phytosterol is esterified by a catalyst containing a metal element, a certain amount of the metal element will remain in the reaction system. If the fatty acid phytosterol ester is used in the food field, the residue of the metal element will be Causes potential harm to the human body, so it is necessary to minimize or avoid metal residues in the esterification reaction. The test results of silica show that silica does not have any residue during the esterification reaction....

Embodiment 3

[0075] Example 3: Color detection of fatty acid phytosterol esters prepared under different reaction conditions

[0076] Table 3: Color detection of fatty acid phytosterol esters prepared under different reaction conditions

[0077] Experiment number

colour

1-5

0.5R, 5Y

6

0.5R,5Y

7

0.5R,5Y

8

0.5R,5Y

9

0.6R,5Y

10

0.4R,4Y

11

0.4R,4Y

12

0.5R,5Y

13

0.5R,5Y

[0078] 14

0.5R,5Y

15

0.5R,5Y

16

0.5R,5Y

17

0.5R,5Y

18

0.5R,5Y

19

0.5R,5Y

20

0.5R,5Y

21

0.5R,5Y

22

7R,10Y

23

7R,10Y

24

7R,10Y

[0079] The color of grease is detected by the GB / T 22460-2008 method, R is the abbreviation for red, Y is the abbreviation for yellow, and the number is the color value measured by this method. The higher the color value, the darker the color.

[0080] From the above color detection data, the preparation of fatty acid phytosterol esters using silica as a catalyst obtains a good grease color. Compared with silica gel, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com