Hydraulic locking knife holder

A hydraulic type, tool holder technology, applied in metal processing and other directions, can solve the problems of reducing precision and enhancing labor intensity, and achieve the effect of improving cutting accuracy, enhancing labor intensity and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

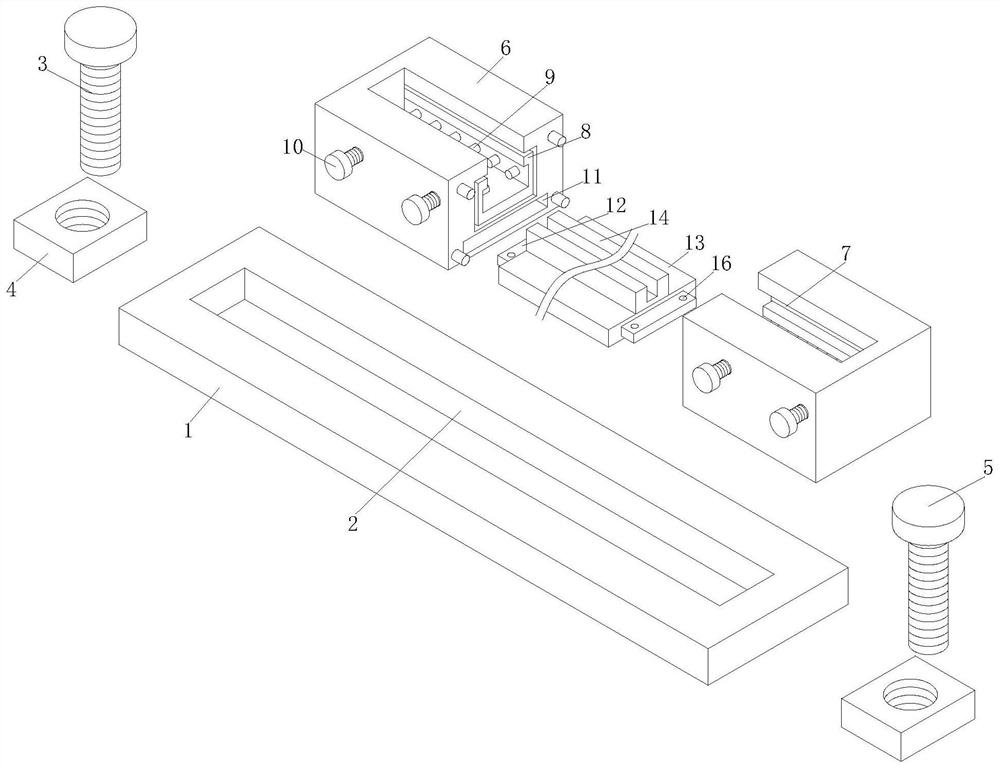

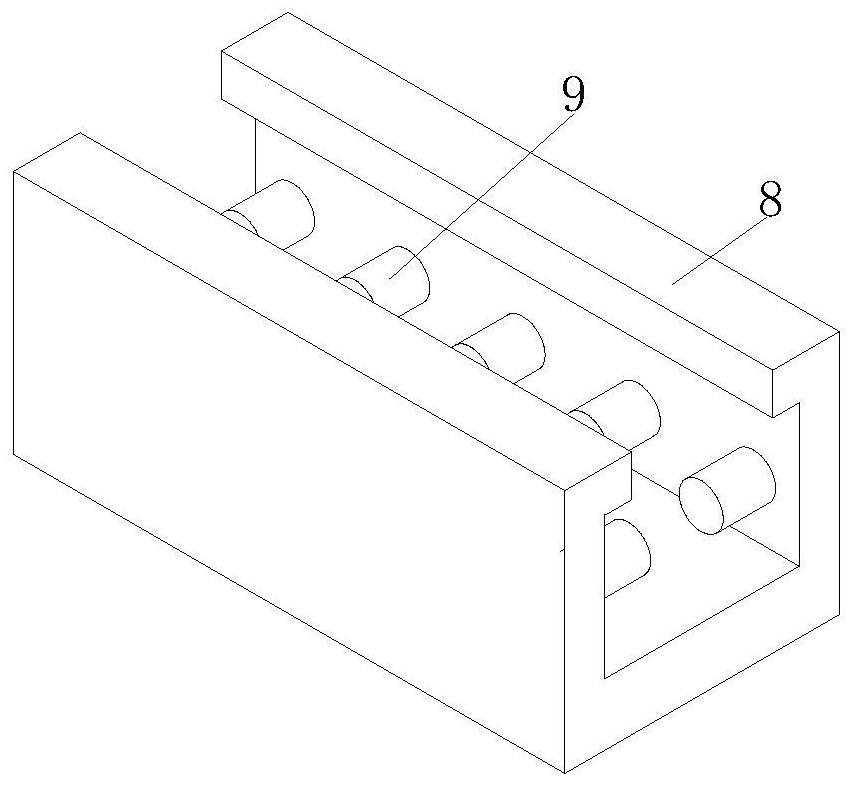

[0028] The hydraulic locking tool of the present embodiment is based on the first embodiment, and the different and improvements are in that the two bottom plate 1 has a slot 11, and the inner cavity activity of the slot 11 is connected. The socket 12, the socket 12 is fixed from one side of the slot 11 fixed to the fixing plate 13, and the top portion of the fixing plate 13 is fixedly coupled with a fixed seat 14, and the locking plate 4 is made of a metal material.

[0029] On the basis of the use of the first example, when the two tool holders 6 are separated, the fixed plate 13 of different lengths can be selected by the distance between the two blade body 6, and then the front and rear positions of the fixed plate 13 can be The socket 12 is inserted into the inner cavity of the slot 11, and the cutter is supported to prevent damage to the cutter.

Embodiment 3

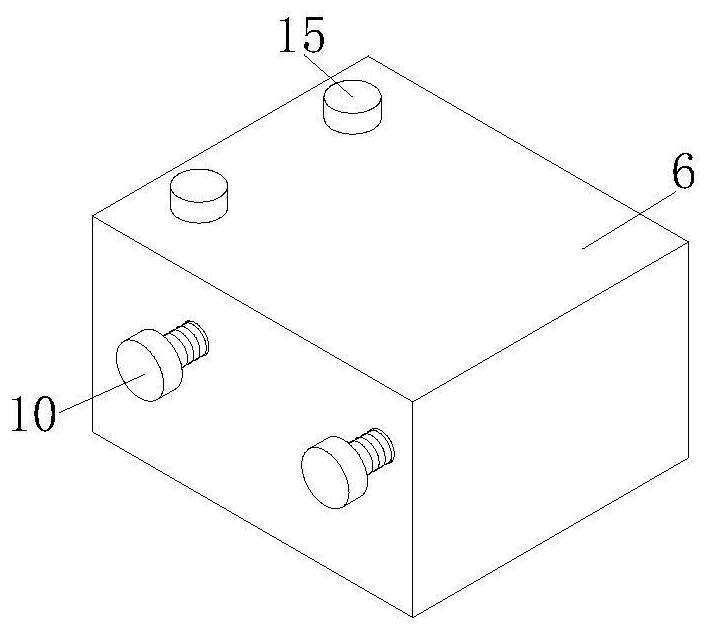

[0031] The hydraulic locking tool of the present embodiment is based on the second embodiment, and the different and improvement is that both both sides of the bottom of the blade body 6 are threaded with a locking bolt 15, and one end of the locking bolt 15 runs through The inner cavity of the slot 11 is threaded with the slot 11, and there is a restricted hole 16 on both sides of the top of the socket 12.

[0032] On the basis of the use of the second embodiment, when the insertion block 12 is inserted into the inner cavity of the slot 11, the locking bolt 15 is threaded with the slot 11, and the socket 12 is fixed, The fixing plate 13 is fixed to the fixed plate 13, thereby enhancing the stability of the two cutting body 6 connections.

Embodiment 4

[0034] The hydraulic locking tool of the present embodiment is based on the third embodiment, and the four angles of the bottom plate 1 are fixed by the side of the bottom plate 1, and the bottom plate 1 is fixed to the center at the bottom of the bottom plate 1 The surface of the pad, and the surface of the guard is provided with a slider, and the front end and the rear end on both sides of the tool holder 6 are opened with the threaded holes used in conjunction with the pressure bolt 10.

[0035] On the basis of the use of the third embodiment, after the adjustment is completed, the connecting bolt is inserted into the threaded hole of the device, then rotates the bolt, and lock the bottom plate 1 and the device, where the protective pad is used to enhance the backplane 1. Protectiveness.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com