Restaurant food residue recycling device

A food residue and recycling device technology, which is applied in household cleaning devices, packaging, loading/unloading, etc., can solve the problems of sewer blockage, water return, waste of labor, food waste sticking to dishes, and dish placement chaos, etc., to achieve The effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

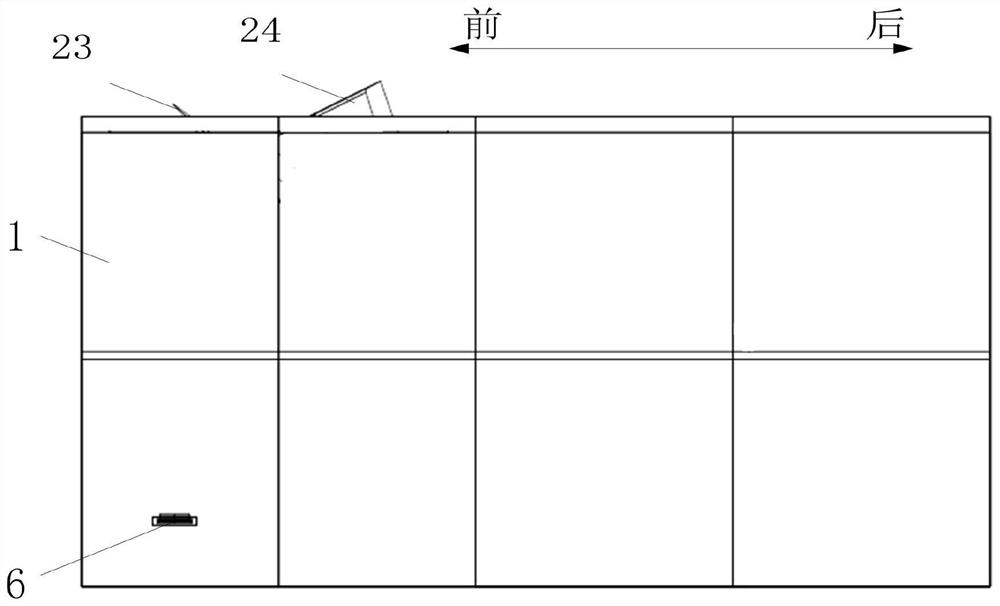

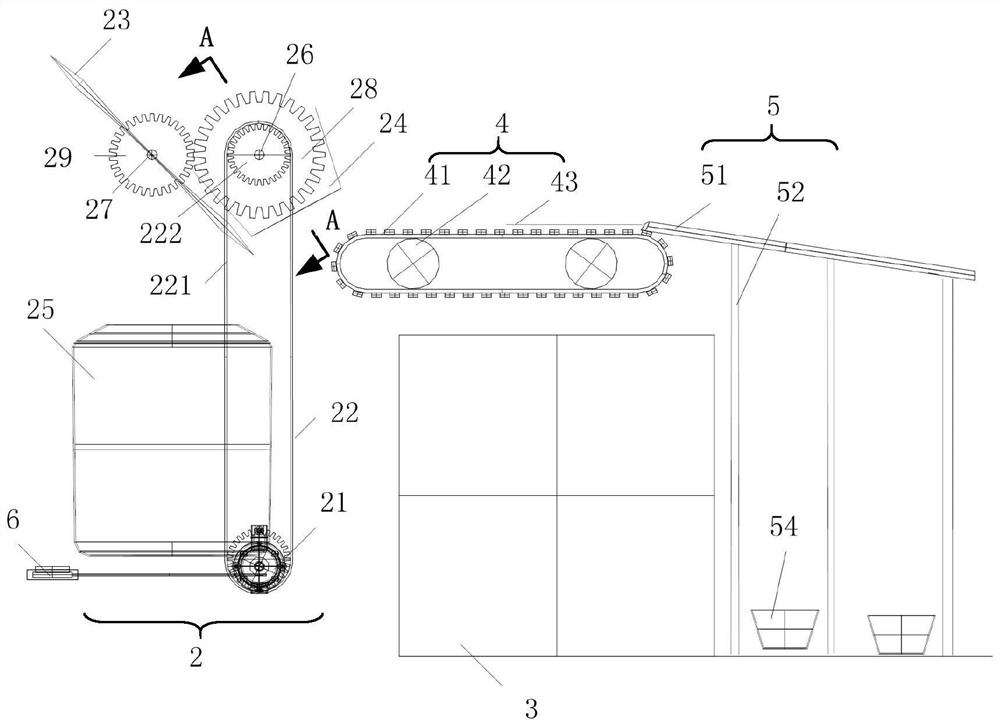

[0037] Such as figure 2 As shown, a restaurant food residue recycling device includes a housing 1, a residue collection mechanism 2 and a battery 3 arranged inside the housing 1, and a foot switch 6 is fixed outside the housing 1;

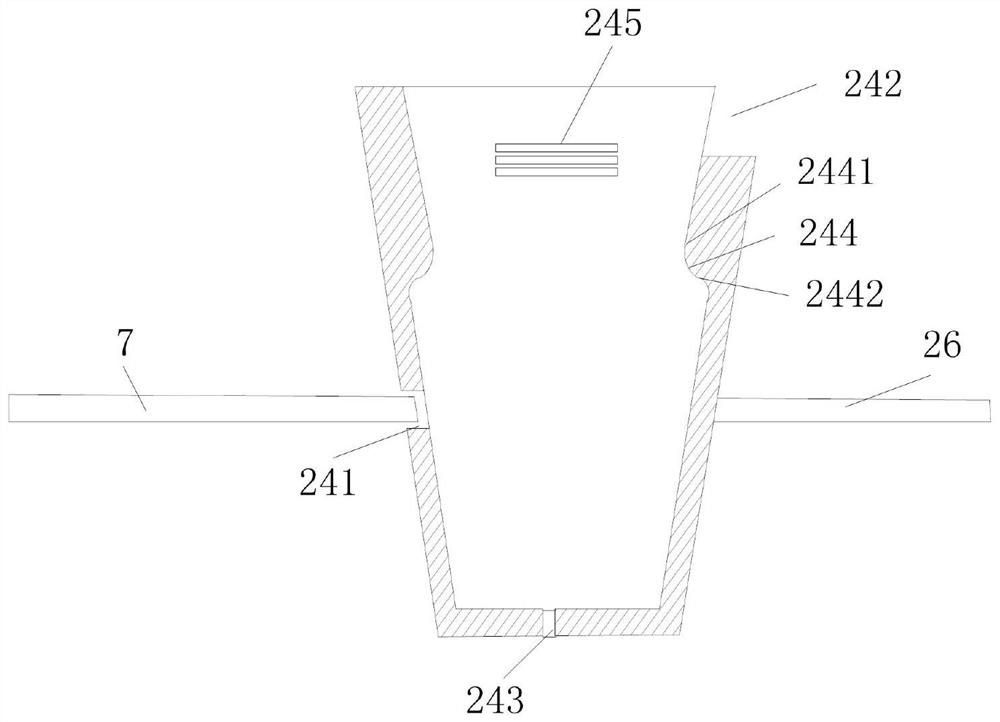

[0038]The residue collection mechanism 2 includes a motor 21, a transmission assembly 22, two arc-shaped scrapers 23, a collection bucket 24, a storage bucket 25, a controller, and a first rotating shaft 26 and a second rotating shaft 27 arranged in parallel. The motor 21 is fixed on the casing 1. The inner bottom provides power for the transmission assembly 22;

[0039] The transmission assembly 22 is drivingly connected to the first rotating shaft 26, the first rotating shaft 26 mesh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com