Photocatalytic oxidation device for in-situ culture or/and biofilm killing as well as use method and application of photocatalytic oxidation device

A technology of photocatalytic oxidation and in-situ cultivation, which is applied in the field of photocatalytic oxidation devices, can solve the problems of difficulty in killing, no biofilm cultivation, integration of in-situ killing and killing, high cost, etc. Effect of small area and reduction of processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

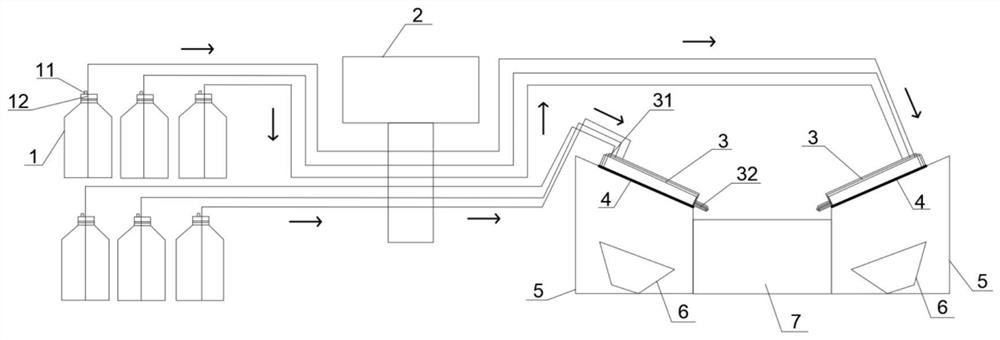

[0030] figure 1 It is a schematic structural view of the photocatalytic oxidation device of the in situ culture or / and killing the biofilm of the present invention. Such as figure 1 As shown, the photocatalytic oxidation device includes a multi-function threaded bottle 1, a multi-channel peristaltic pump 2, a biofilm culture reactor 3, and an ultraviolet lamp 5; the multi-function threaded bottle 1 is provided with an air outlet 11 in which the internal and outer air pressure is provided. The culture liquid exit 12; the biofilm reactor 3 is provided with a culture fluid input opening 31 and a waste liquid exclusion port 32; the culture liquid outlet 12 is connected to the culture fluid input port 31 via a sterile line. Multi-channel peristaltic pump 2 is disposed on the sterile lines; the biofilm culture reactor 3 is placed on the inclined bracket 5, the UV 6 (UVA band, its wavelength of 320 ~ 420 nm) is provided The lower end of the biofilm culture reactor 3.

[0031] The phot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com