a fe 3 o 4 /zno nanocomposite and its synthesis method

A technology of nanocomposites and synthesis methods, applied in the field of Fe3O4/ZnO nanocomposites and their synthesis, can solve problems affecting the recovery and recycling of nanocomposites, unsatisfactory magnetic properties, and low mass specific gravity, etc., and achieve suitable scale Promotion of globalization, strong magnetism, beneficial to recovery and recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

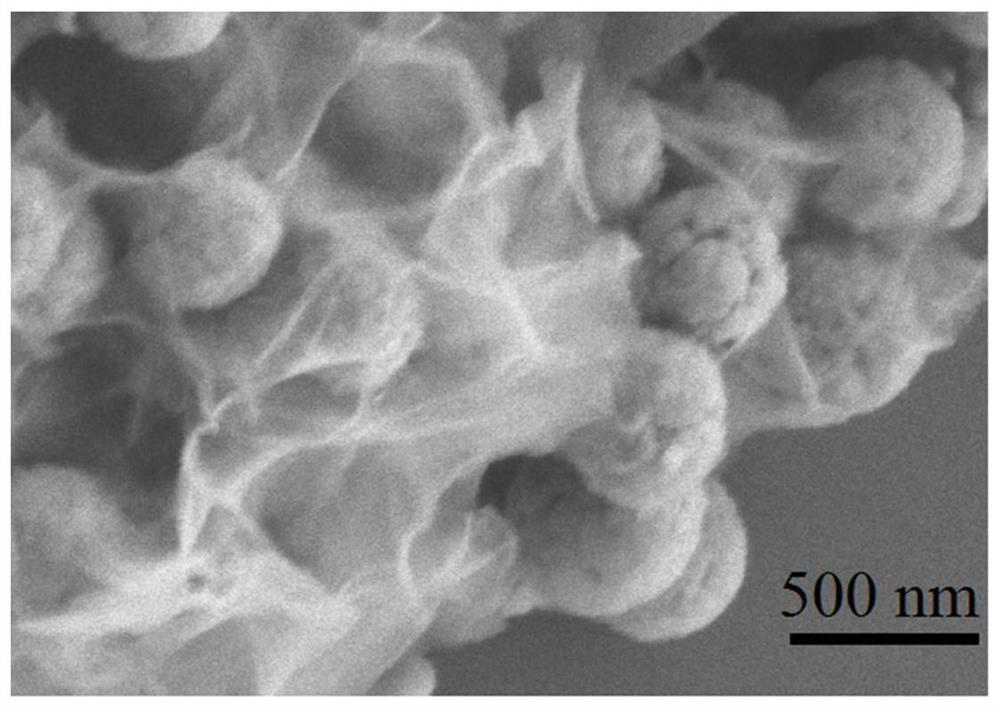

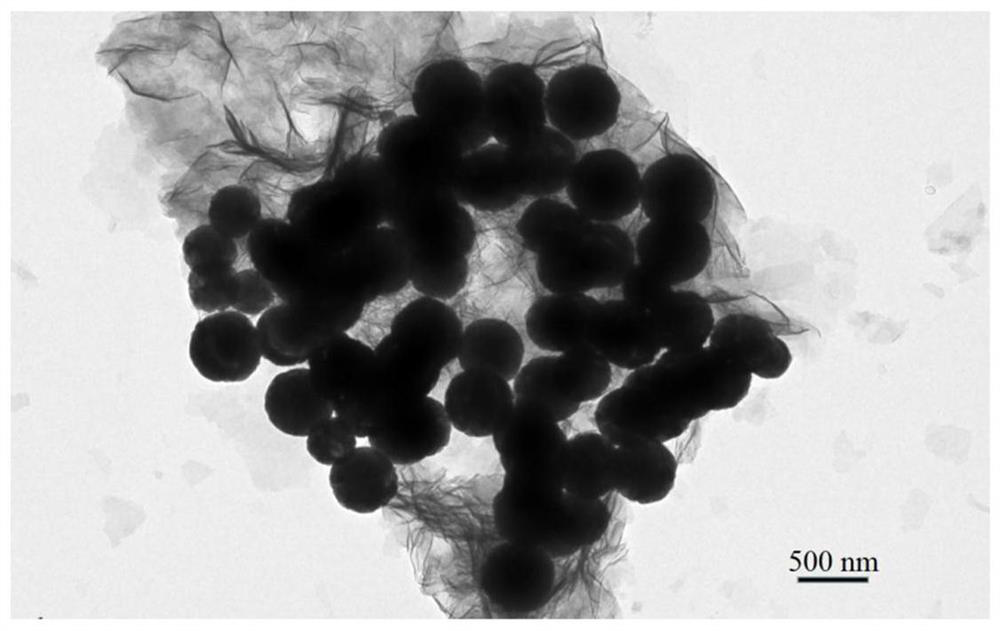

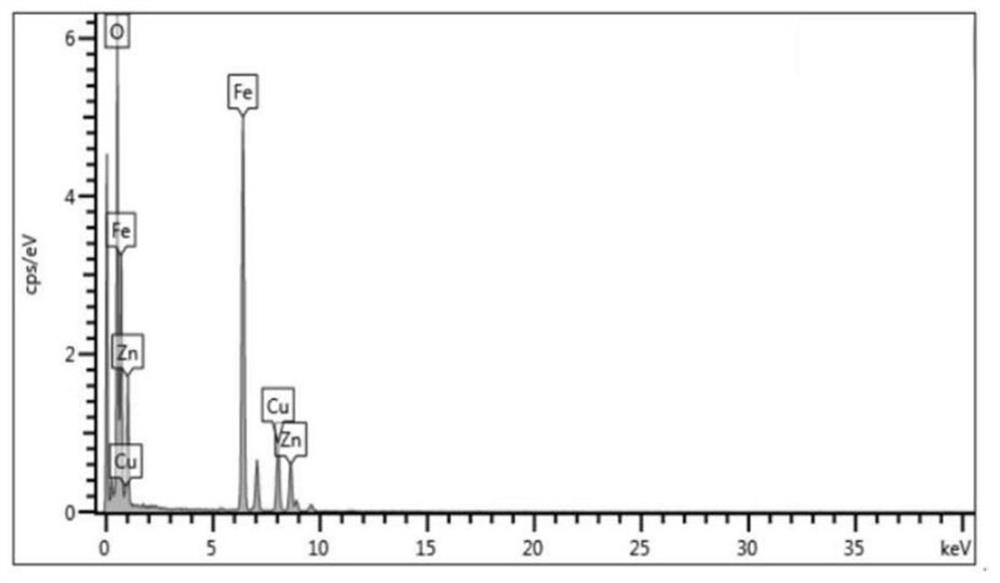

Image

Examples

Embodiment 1

[0059] a kind of Fe 3 o 4 The synthetic method of / ZnO nanocomposite, comprises the steps:

[0060] (1) Preparation of Fe 3 o 4 : Take 1.05g of FeCl 3 ·6H 2 O was dispersed in 40 mL of ethylene glycol and stirred until completely dissolved to become a homogeneous clear solution, followed by the addition of 1.7 g of NaAc and 0.6 g of polyethylene glycol. The mixed solution was vigorously stirred for 15 min, then transferred to a 100 mL polytetrafluoroethylene-backed reaction kettle, heated at 160 °C for 4 h, taken out, and naturally cooled to room temperature. Recycling and Separation of Black Fe Using Magnets 3 o 4 The product was washed several times with twice distilled water and absolute ethanol, and dried under vacuum at 50°C for 10 h;

[0061] (2) Fe 3 o 4 Modification: Weigh 0.15g of prepared Fe 3 o 4 Add magnetic nanoparticles to 40mL ethanol solution of MAA with a concentration of 0.15mM. After shaking for 16h, the black product is recovered with a magnet an...

Embodiment 2

[0066] a kind of Fe 3 o 4 The synthetic method of / ZnO nanocomposite, comprises the steps:

[0067] (1) Preparation of Fe 3 o 4 : Take 1.65g of FeCl 3 ·6H 2 O was dispersed in 30 mL of ethylene glycol, stirred until completely dissolved into a homogeneous clear solution, then 2.8 g of NaAc and 0.7 g of polyethylene glycol were added. The mixed solution was vigorously stirred for 20 min, then transferred to a 50 mL polytetrafluoroethylene-based reaction kettle, heated at 150 °C for 3 h, taken out, and cooled to room temperature naturally. Recycling and Separation of Black Fe Using Magnets 3 o 4 The product was washed several times with double distilled water and absolute ethanol, and dried in vacuum at 70°C for 6h;

[0068] (2) Fe 3 o 4 Modification: Weigh 0.2g of prepared Fe 3 o 4 Magnetic nanoparticles were added to 30mL of 0.18mM polyvinylpyrrolidone (PVP) ethanol solution, and after shaking for 15 hours, the black product was recovered with a magnet and washed th...

Embodiment 3

[0071] a kind of Fe 3 o 4 The synthetic method of / ZnO nanocomposite, comprises the steps:

[0072] (1) Preparation of Fe 3 o 4 : Take 1.95g of FeCl 3 ·6H 2 O was dispersed in 40 mL of ethylene glycol and stirred until completely dissolved to form a homogeneous clear solution, followed by the addition of 1.8 g of NaAc and 1.7 g of polyethylene glycol. The mixed solution was vigorously stirred for 25 min, then transferred to a 100 mL polytetrafluoroethylene-backed reactor, heated at 160 °C for 4 h, taken out, and cooled to room temperature naturally. Recycling and Separation of Black Fe Using Magnets 3 o 4 The product was washed several times with double distilled water and absolute ethanol, and dried in vacuum at 80°C for 5h;

[0073] (2) Fe 3 o 4 Modification: Weigh 0.3g of prepared Fe 3 o 4 Magnetic nanoparticles were added to 60 mL of 0.18 mM Tween 80 ethanol solution, and after 18 hours of shaking reaction, the black product was recovered with a magnet, and wash...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com