A self-flowing underground soil infiltration system without power

A soil infiltration and self-flowing technology, which is applied in the field of unpowered self-flowing underground soil infiltration system, can solve the problems of high operating efficiency, small footprint, low operation and maintenance costs, and achieve high operating efficiency and land occupation. Small area, the effect of improving the energy efficiency of treatment and purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

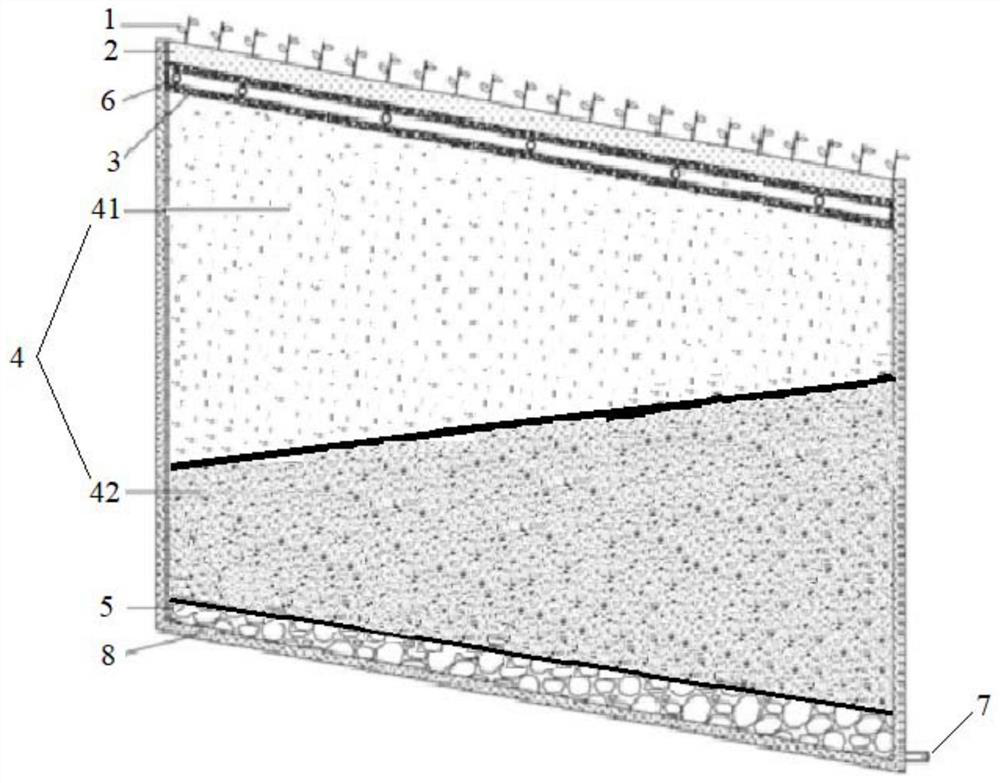

[0043] The test of this example was carried out in a 12° slope outside the farmyard of a villager in Wangdian Village, Sanyuan County, Xianyang City, Shaanxi Province, and the test time was from January to February 2021. System structure such as figure 1 As shown, from top to bottom, there are: plant layer 1, planting soil layer 2, water distribution layer 3, first soil infiltration layer 41, second soil infiltration layer 42, supporting layer 5, infiltration system Anti-seepage walls 8 are set around and at the bottom.

[0044] The plant layer 1 is planted with holly and Chinese rose, the planting soil layer 2 is composed of 50cm thick cultivated soil; the water distribution layer 3 is 15cm thick and is composed of coarse sand with a particle size of about 4cm; In the water layer 3, the water distribution pipe 6 is composed of a DN10PVC water distribution main pipe and a DN5PVC water distribution branch pipe. The water distribution main pipe is set along the direction from t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com