Carbon fiber modification method and product thereof

A carbon fiber modification technology, which is applied in the field of carbon fiber modification methods and its products, can solve the problems of carbon fiber mechanical properties, poor toughness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

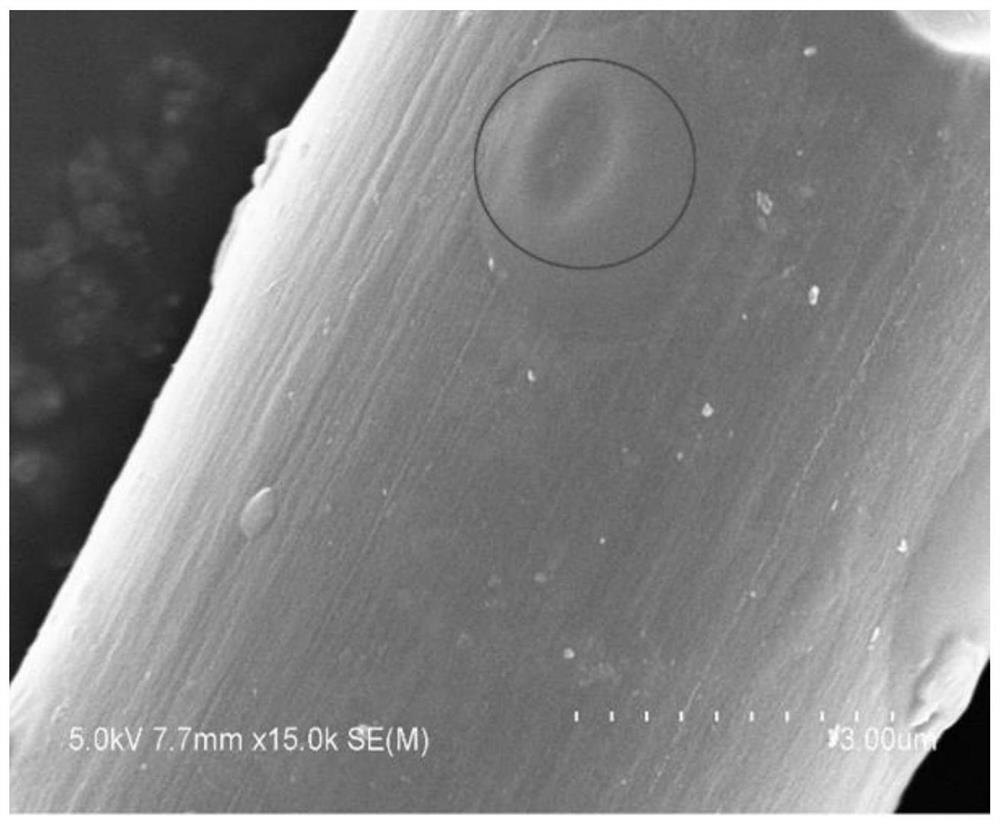

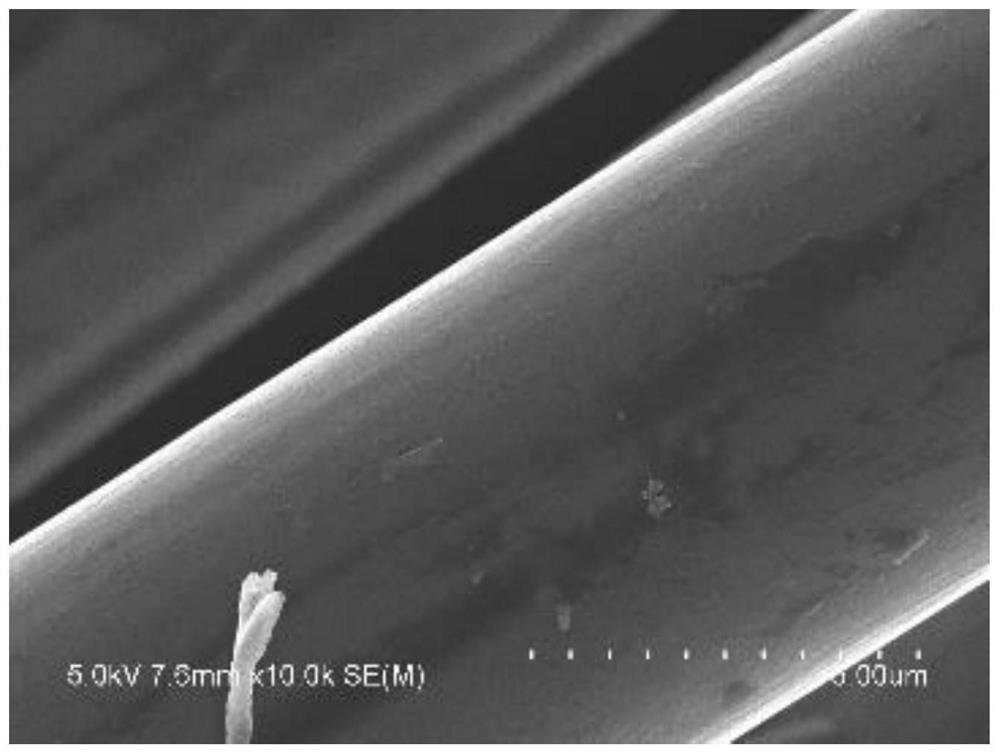

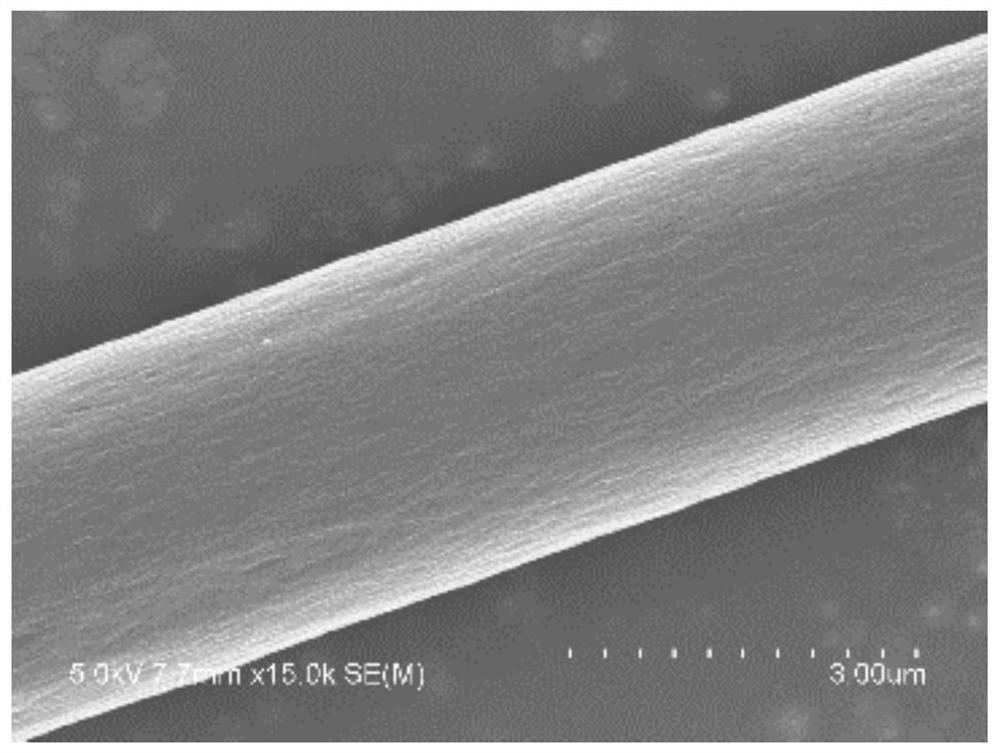

Image

Examples

Embodiment 1

[0029] (1) Place the bundled 12K carbon fiber produced by Toray in Japan in an acetone solution at a constant temperature of 70°C for 24 hours, then wash it alternately with absolute ethanol and deionized water to remove the sizing agent, dust and oil on the surface of the fiber, and then Dry and cool at 80°C for 24 hours;

[0030] (2) Use the carbon fiber treated in step (1) as the substrate, fix it on the cardboard in parallel, install the carbon target on the cathode plate, place the substrate under the substrate support, and perform magnetron sputtering under the following conditions Processing: sputtering power 250W, magnetron sputtering pressure 1Pa, sputtering time 30min, background vacuum 2×10 -3 Pa, the distance between the target and the substrate is 4 cm, high-purity argon (99.999%) is used as the working gas, the flow rate of the argon gas is 80 ml / min, and the substrate holder rotates at a speed of 30 r / min.

[0031] (3) The carbon fibers treated in step (2) are ...

Embodiment 2

[0039] Same as Example 1, the difference is that the sputtering power is 250W, the magnetron sputtering pressure is 1Pa, the sputtering time is 45min, and finally it is treated in a vacuum furnace at 200°C for 40min. The tensile breaking strength of the treated bundled carbon fiber is 0.8956KN.

Embodiment 3

[0041] Same as Example 1, the difference is that under the condition of 250W, the magnetron sputtering pressure is 1Pa, the sputtering time is 45min, and the heat treatment condition is 300°C for 40min. The tensile breaking strength of the treated bundled carbon fiber is 0.8533KN.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile breaking strength | aaaaa | aaaaa |

| Tensile breaking strength | aaaaa | aaaaa |

| Tensile breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com