Noise reduction structure at top end of sound barrier based on diffuser coupling micro-perforated plate

A technology of micro-perforated plate and diffusion structure, which is applied in the direction of noise absorption devices, buildings, etc., can solve the problems of reduced sound absorption performance, reduced insertion loss of sound barriers, etc., and achieves improved noise reduction, small structure width, and good noise reduction effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

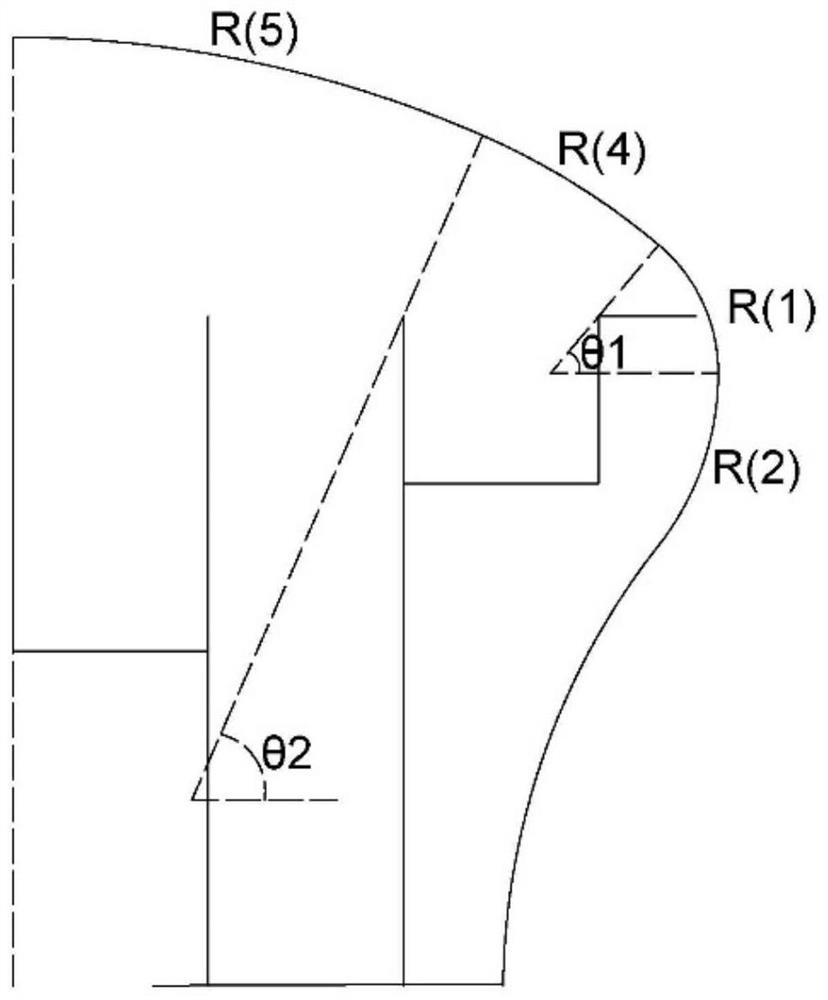

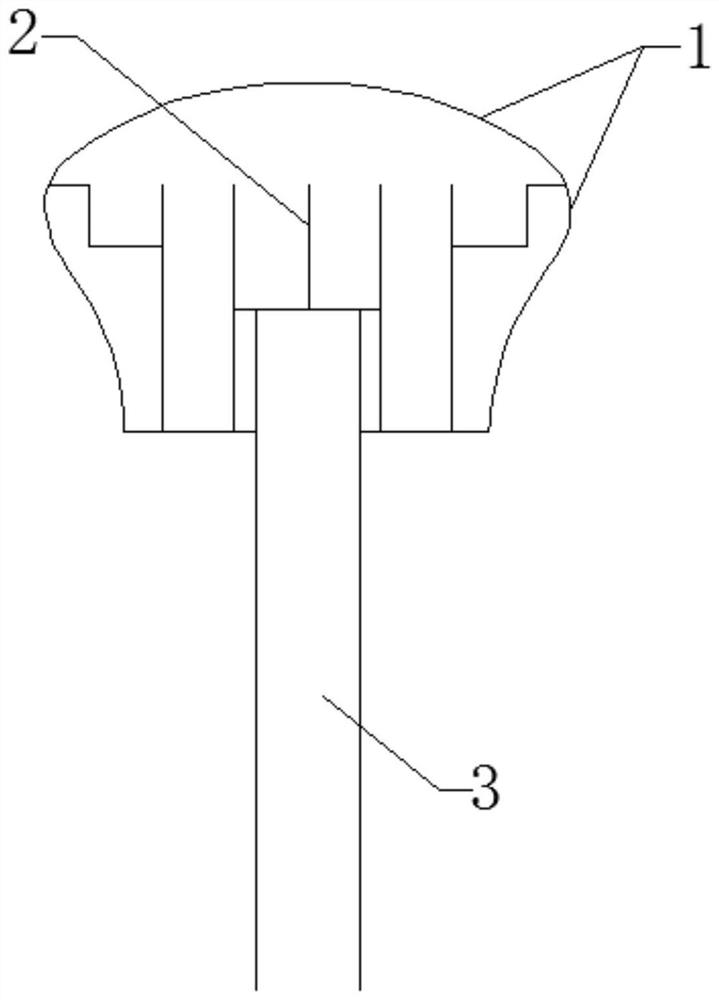

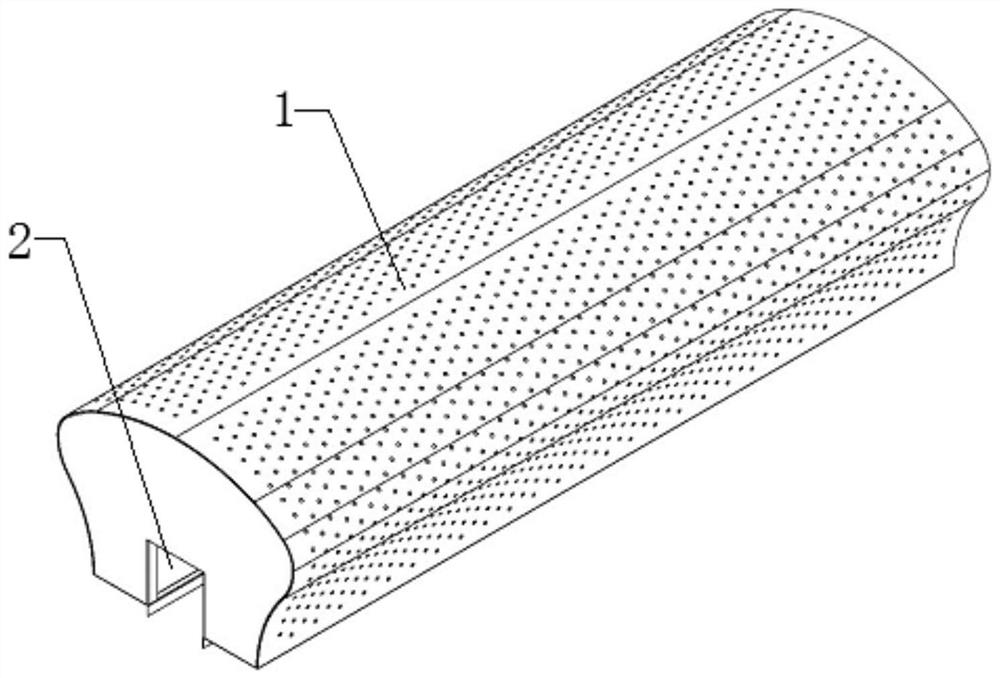

[0030] The present invention provides a noise reduction structure at the top of the sound barrier based on a diffuser coupling micro-perforated plate. The diffuser structure 2 adopts a quadratic remainder sequence diffuser, and the quadratic remainder sequence diffuser is a basic structure based on a quadratic remainder sequence. Each groove The depth of is sorted according to the law of the quadratic residue sequence, and the form of the quadratic residue sequence is:

[0031] S n =n 2 mod N

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com