Pipeline traction construction method

A construction method and pipeline technology, applied in drilling equipment and methods, earthwork drilling, wellbore lining and other directions, can solve the problems of increasing construction difficulty, high construction difficulty, easy collapse of drilling holes, etc., to ensure the success rate, The effect of reducing friction and strengthening the hole wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiments of the present invention will be further described below with reference to the accompanying drawings and embodiments.

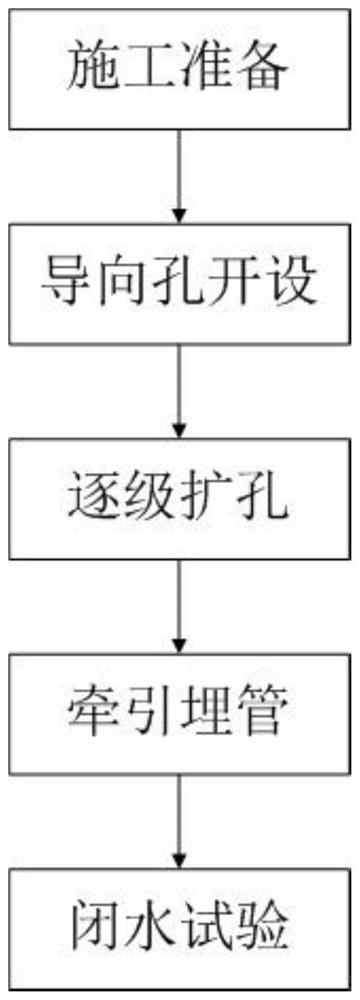

[0021] like figure 1 As shown in the figure, the pipeline traction construction method includes the following steps: S1, construction preparation, complete the pre-construction preparation, and determine the opening trajectory of the drilling hole; S2, open the pilot hole, use a drilling rig and cooperate with a guiding instrument to follow the pre-designed trajectory Open a pilot hole; S3, step by step reaming, select a drill with a diameter that is 1.3 to 1.7 times the inner diameter of the pilot hole, complete one-time reaming along the pilot hole, and select drills with a diameter that increases in order of multiples of 1.3 to 1.7 Complete the reaming of the drilled hole until the drilled hole after reaming matches the outer diameter of the buried pipeline. During the reaming process, inject the admixture into the drilled h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com