Radial bearing and air suspension centrifugal compressor

A technology of radial bearings and bearing sleeves, applied in the field of compressors, can solve the problems of material and cost waste, affect machine life and reliability, and cannot eliminate vibration well, and achieve good adaptability and high damping characteristics , good adaptability and replaceability, and the effect of improving the operating range of the speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

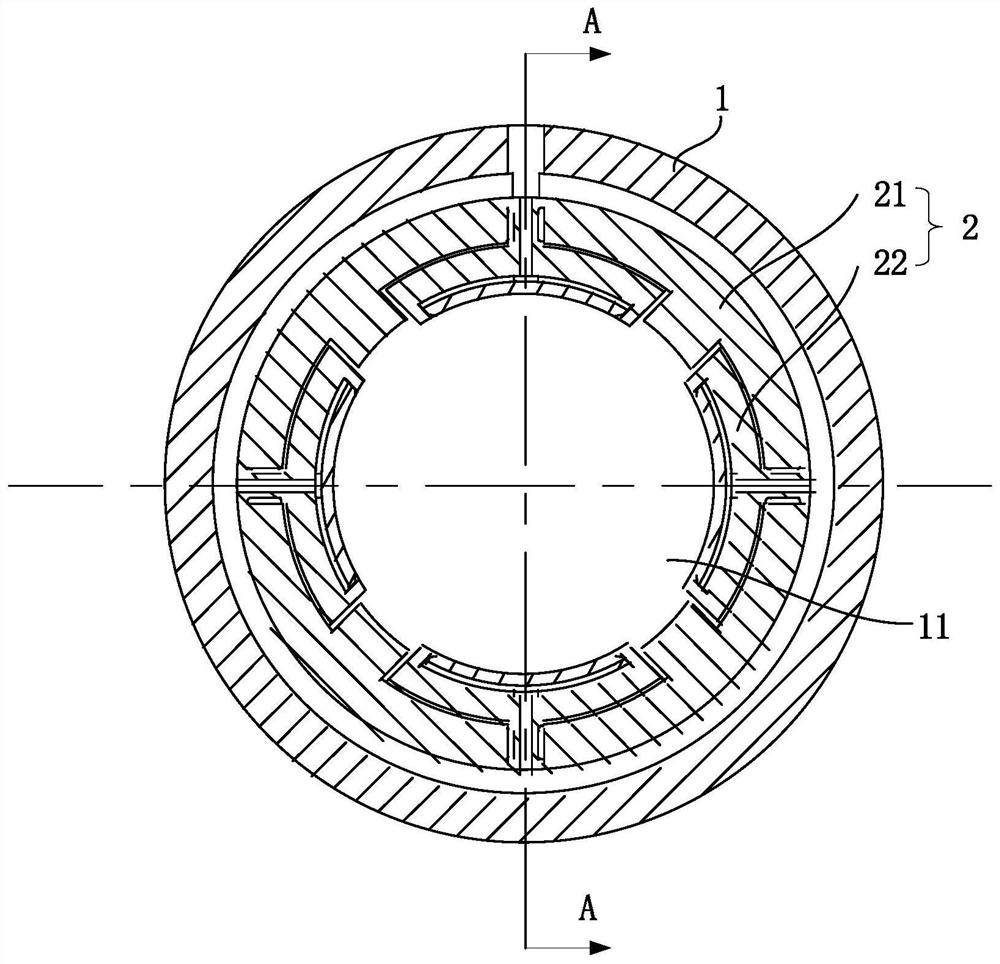

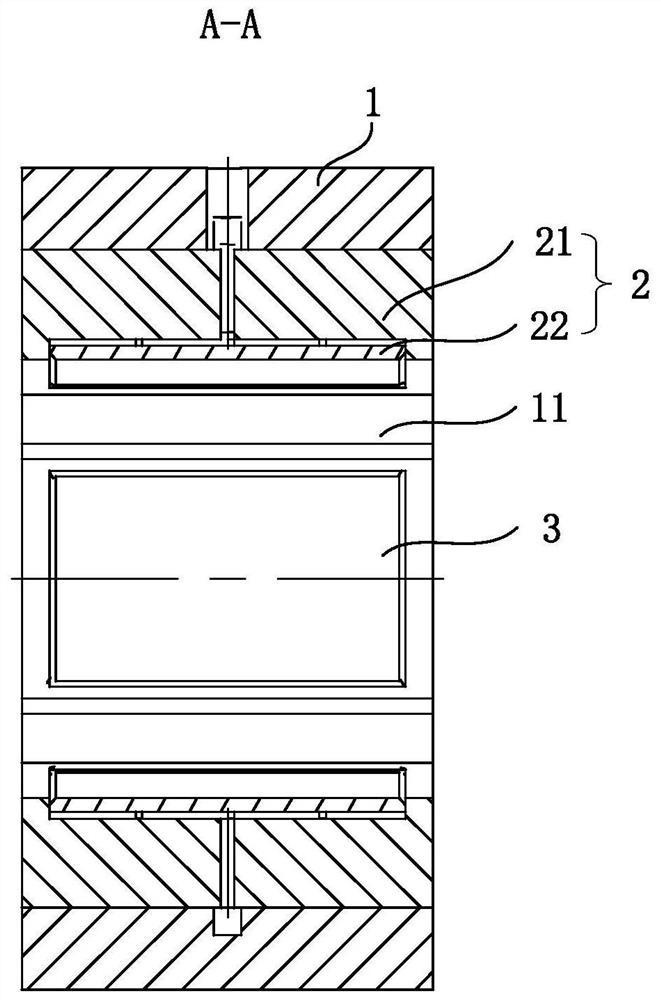

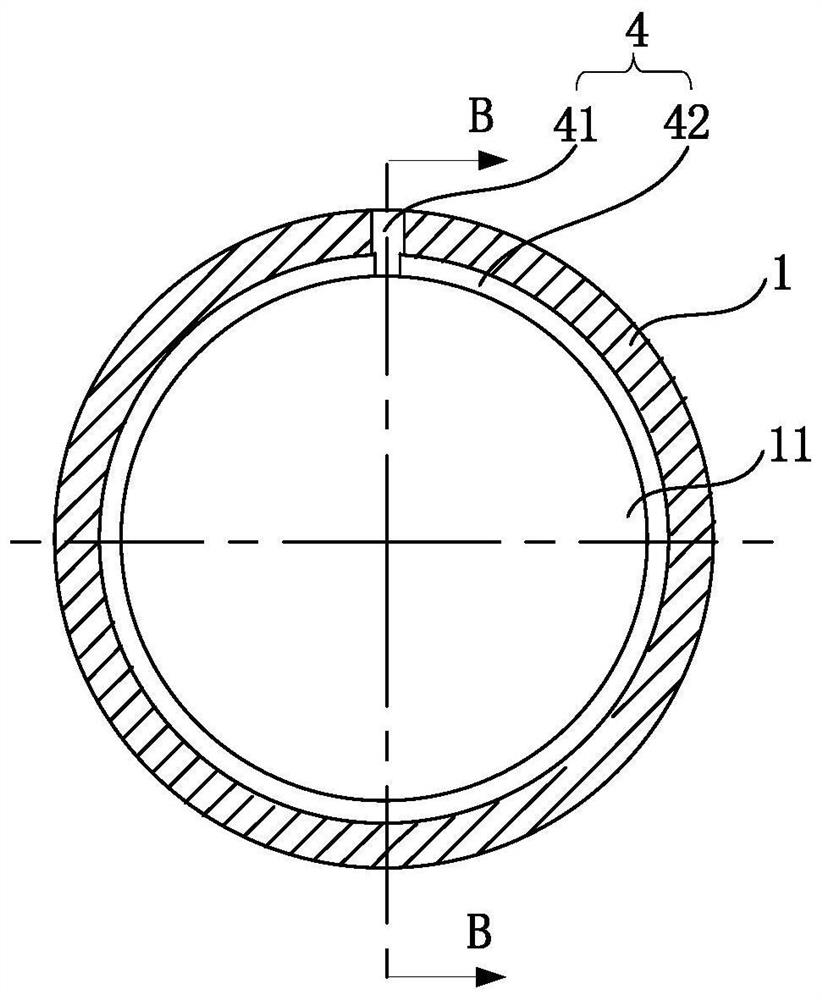

[0041] Combine below Figure 1 to Figure 12 The technical solution provided by the present invention is described in more detail.

[0042] An embodiment of the present invention provides a radial bearing, including a bearing sleeve 1 , a bearing base 2 and a graphite part 3 . The bearing sleeve 1 includes a through hole 11 in which the rotating shaft 7 is mounted. The bearing base 2 includes a cylinder 21 mounted on the inner wall of the through hole 11 and a bearing bush 22 connected to the cylinder 21 through a connecting portion 23 . The connecting portion 23 is configured to enable the bearing bush 22 to move relative to the joint between the cylindrical body 21 and the bearing bush 22 under the action of an external force. The graphite component 3 is installed on the side of the bearing bush 22 away from the barrel 21 .

[0043] The radial bearing is used for installing the rotating shaft 7 . The bearing sleeve 1 is used for installing the bearing base 2, and the bear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com