Novel flash furnace bottom brick local maintenance method

A technology for furnace bottom bricks and flash furnaces, applied in furnaces, lining repairs, furnace components, etc., can solve the problems of difficult replacement of furnace bottom refractory bricks, high economic costs, and difficulty in dismantling, and reduce the risk of copper infiltration , reduce maintenance costs, and reduce the risk of copper leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

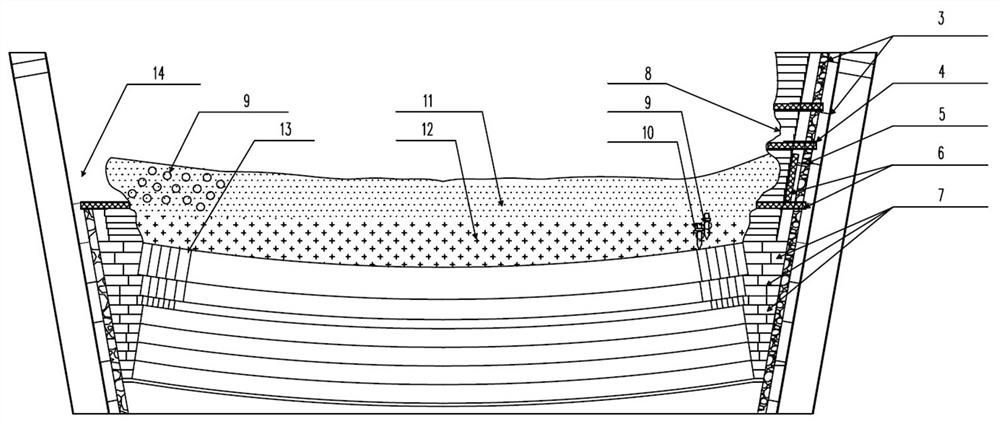

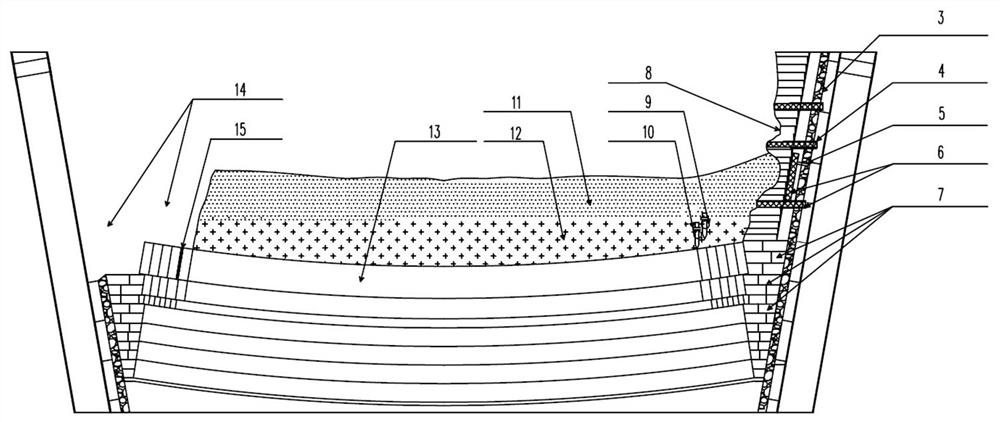

[0031] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

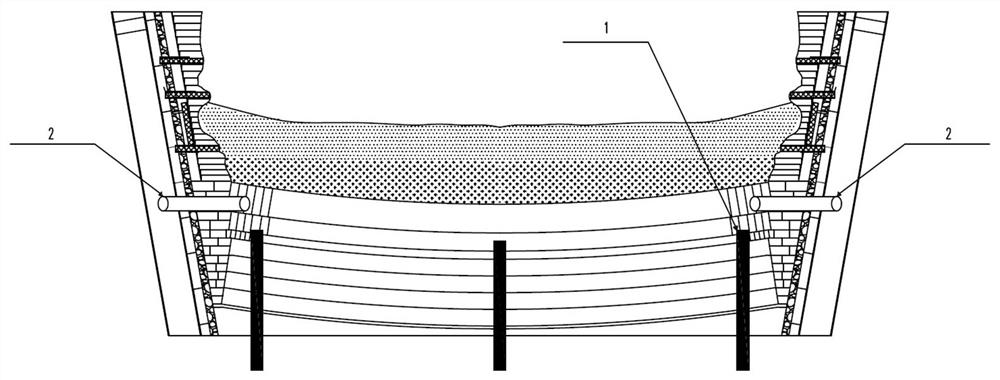

[0032] like Figures 1 to 10 Shown, this novel flash furnace bottom brick partial maintenance method of the present invention, the steps are as follows:

[0033] S1. Determine the scope of maintenance. Before shutting down the furnace, judge the degree of loss of furnace bottom bricks 131 and the scope of maintenance according to the temperature change at the bottom of the sedimentation tank. Consider no maintenance in areas with small temperature changes, and consider maintenance in areas where temperature changes are obvious or temperature fluctuations are significantly aggravated.

[0034] S2. Sampling: determine the degree of pulverization of the furnace bottom brick 131 by drilling samples at the furnace wall of the sedimentation tank near the bottom of the furnace. When ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com