Finished product testing system and method for automobile magnesium-aluminum alloy hub production

A magnesium-aluminum alloy, testing system technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the problems of low reliability, deviation of test results, low test efficiency, etc. The effect of reliability, improving accuracy, and improving test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

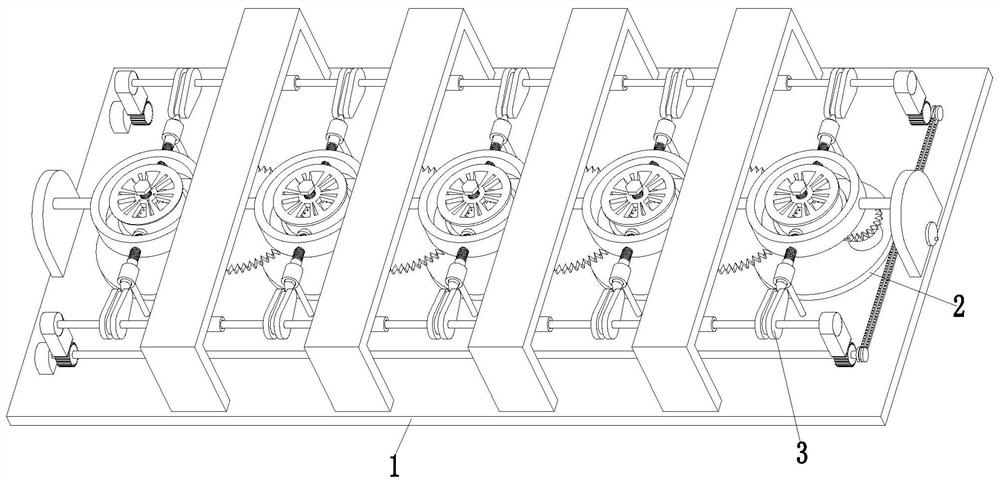

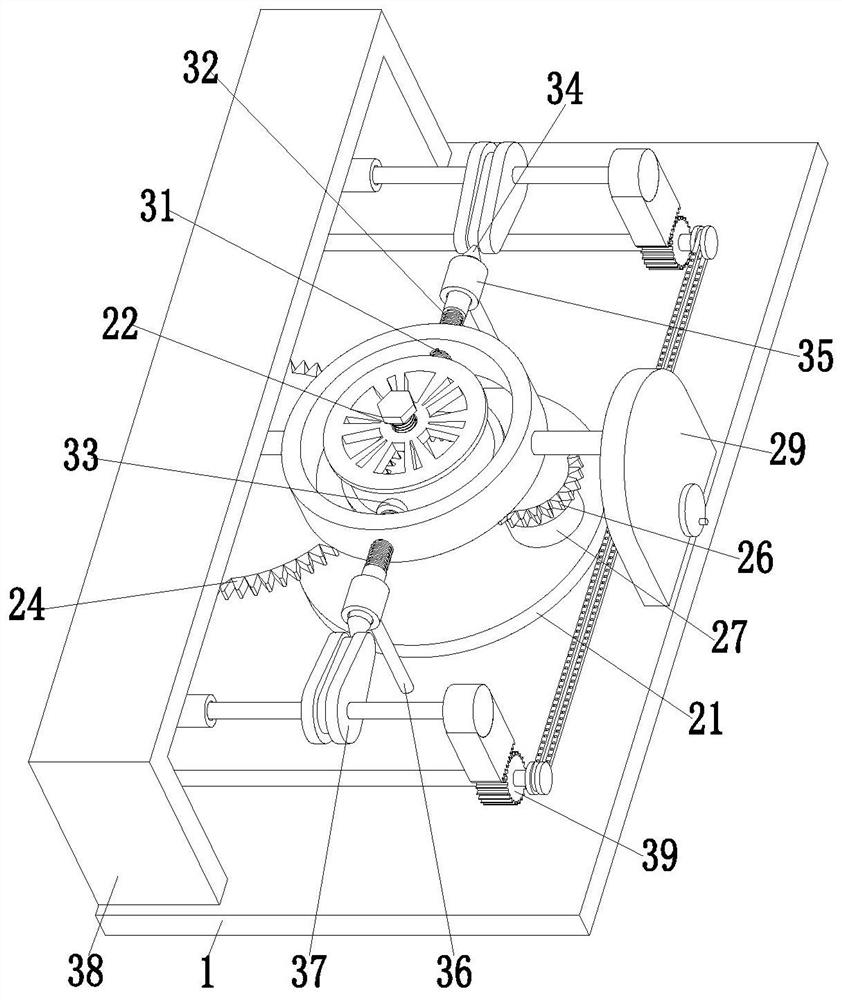

[0032] like Figure 1 to Figure 6 As shown, a finished product test system for the production of magnesium-aluminum alloy wheels for automobiles includes a base plate 1, a support limit device 2 and an extrusion test device 3. An extrusion testing device 3 is installed on the limiting device 2 through a sliding fit.

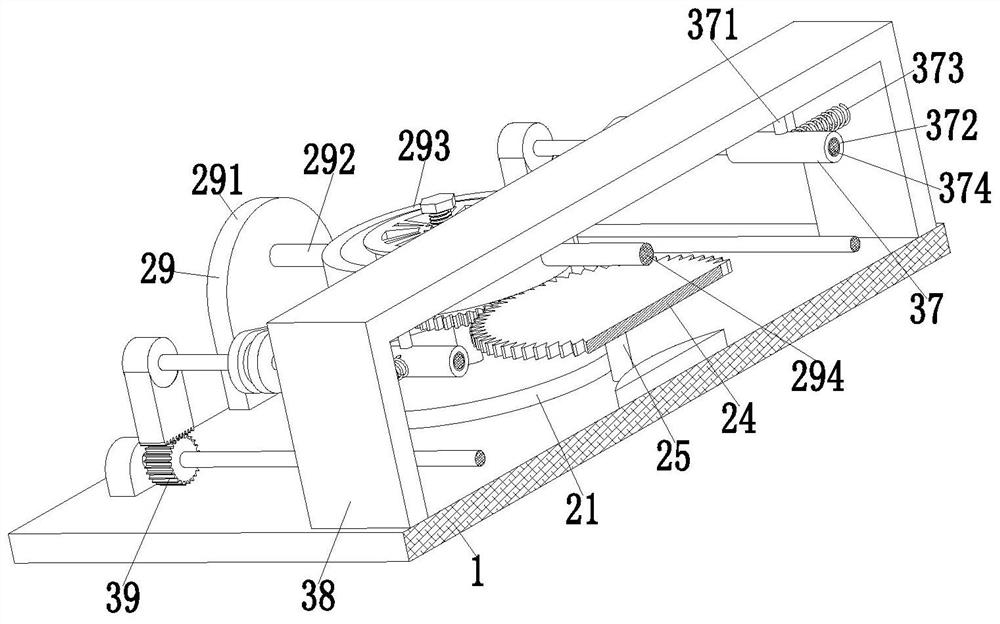

[0033]The support limiter 2 includes a support disc 21, a support rod 22, a gear plate 23, a guide gear 24, a gear shaft 25, a driving gear 26, a driving motor 27, a pressure sensing mechanism 28 and a limit mechanism 29. The middle part of the upper end surface of the bottom plate 1 is uniformly equipped with a support circular plate 21, and the middle part of the support circular plate 21 is equipped with a support rod 22 through a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com