Test methods for performance parameters of glue

A testing method and performance technology, applied in the testing field of glue performance parameters, can solve the problems of inability to directly measure, difficult to provide DK and DF, expensive testing instruments, etc., achieve small consistency error, improve testing accuracy, and high processing accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

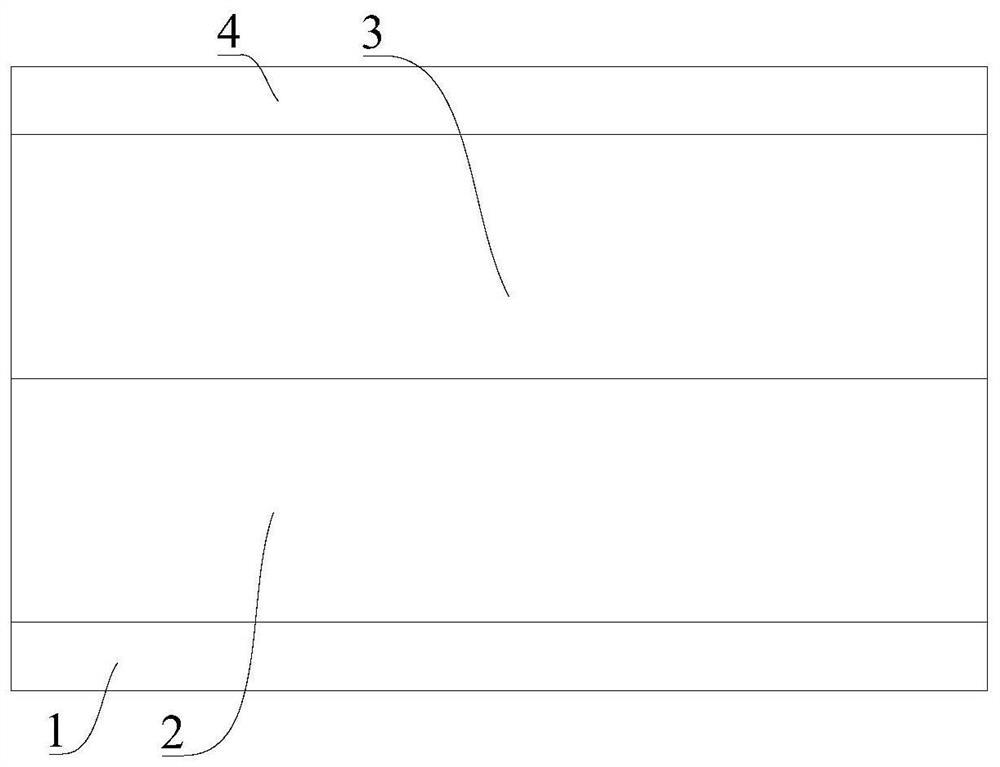

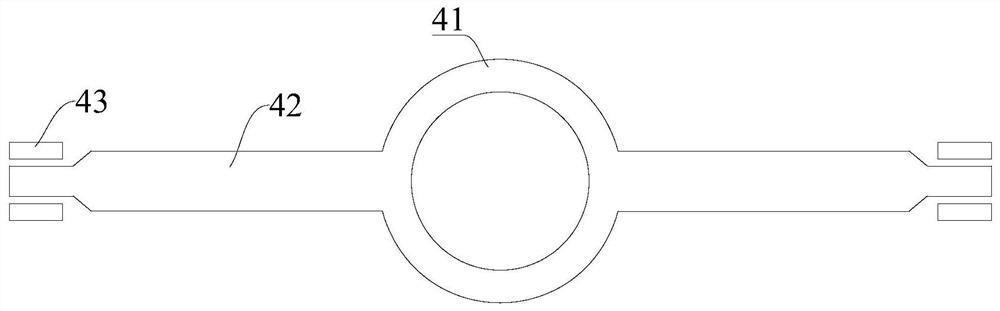

[0054] Please refer to figure 1 and figure 2 , Embodiment one of the present invention is: the test method of glue performance parameter, comprises the following steps,

[0055]Obtain the sample to be tested, the sample to be tested includes the antenna formation layer 1, the adhesive layer 2 to be tested, the PCB board dielectric layer 3 and the circuit layer 4 sequentially stacked from bottom to top; the circuit layer 4 includes a resonant ring 41, a microstrip line 42 and a radio frequency connector 43, the two ends of the microstrip line 42 are respectively connected to the resonant ring 41 and the radio frequency connector 43, specifically, the number of the microstrip line 42 is two, and the two microstrip lines 42 Collinear setting, the resonant ring 41 is located between the two microstrip lines 42; the thickness of the adhesive layer 2 to be tested is equal to the thickness of the PCB dielectric layer 3, preferably, the PCB dielectric The thickness of layer 3 is 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com