Light-emitting diode and manufacturing method thereof

A technology of light-emitting diodes and manufacturing methods, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of insufficient expansion efficiency, poor antistatic ability, and insufficient brightness, so as to improve current congestion and reduce ESD explosion points , Improve the effect of antistatic ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

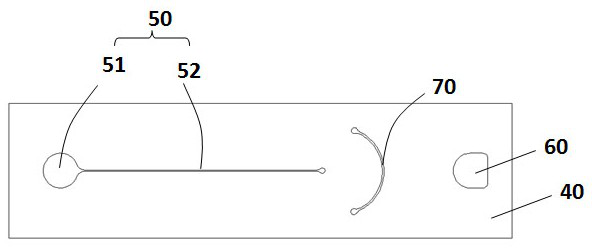

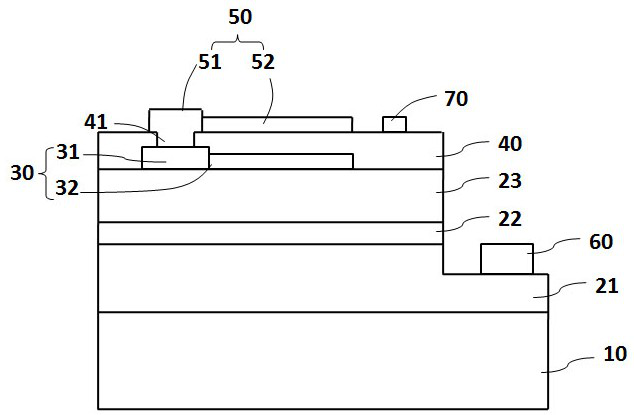

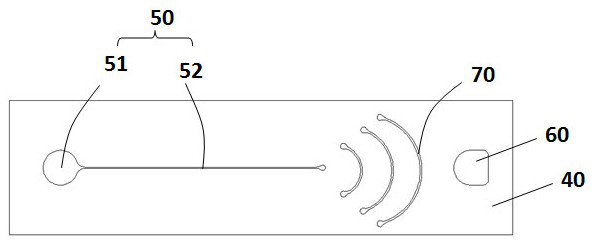

[0022] See attached figure 1 , the light-emitting diode disclosed in the present invention at least includes a substrate 10, a first conductivity type semiconductor layer 21, a light emitting layer 22, a second conductivity type semiconductor layer 23, and the first conductivity type semiconductor layer 21 and the second conductivity type semiconductor layer respectively Layer 23 electrically connects the first electrode 60 and the second electrode 50, wherein the second electrode 50 includes a pad portion 51 and an extension portion 52, and there is an extension portion between the end of the extension portion 52 and the first electrode 60 for expanding the current 70.

[0023] See attached figure 2 , wherein the material of the substrate 10 can be selected from Al 2 o 3 , SiC, GaAs, GaN, AlN, GaP, Si, ZnO, MnO any one or a combination of several. In this embodiment, a sapphire substrate 10 (sapphire substrate) is taken as an example, and the lattice direction may be (00...

Embodiment 2

[0040] In order to manufacture the above light-emitting diode, this embodiment provides a manufacturing method, the specific steps are as follows:

[0041] Step 1, providing a substrate 10, and sequentially depositing a first conductivity type semiconductor layer 21, a light emitting layer 22, and a second conductivity type semiconductor layer 23 on the surface of the substrate 10;

[0042] Step 2, making the first electrode 60 electrically connected to the first conductivity type semiconductor layer 21 and the second electrode 50 electrically connected to the second conductivity type semiconductor layer 23 respectively, wherein the second electrode 50 includes a pad portion 51 and extension 52;

[0043] Step 3, fabricate the extension part 70 for spreading the current on the surface of the second conductivity type semiconductor layer 23 between the end of the extension part 52 and the first electrode 60 .

[0044] In this embodiment, the step of depositing a transparent cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com