Building aggregate separation processing device

A processing device and construction aggregate technology, applied in the direction of solid separation, cleaning methods using tools, and sieving, can solve the problems of waste of water resources, increased separation workload, and inability to ensure uniform mixing and cleaning of the surface of coarse aggregates. Achieve the effect of avoiding secondary pollution and improving cleaning uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

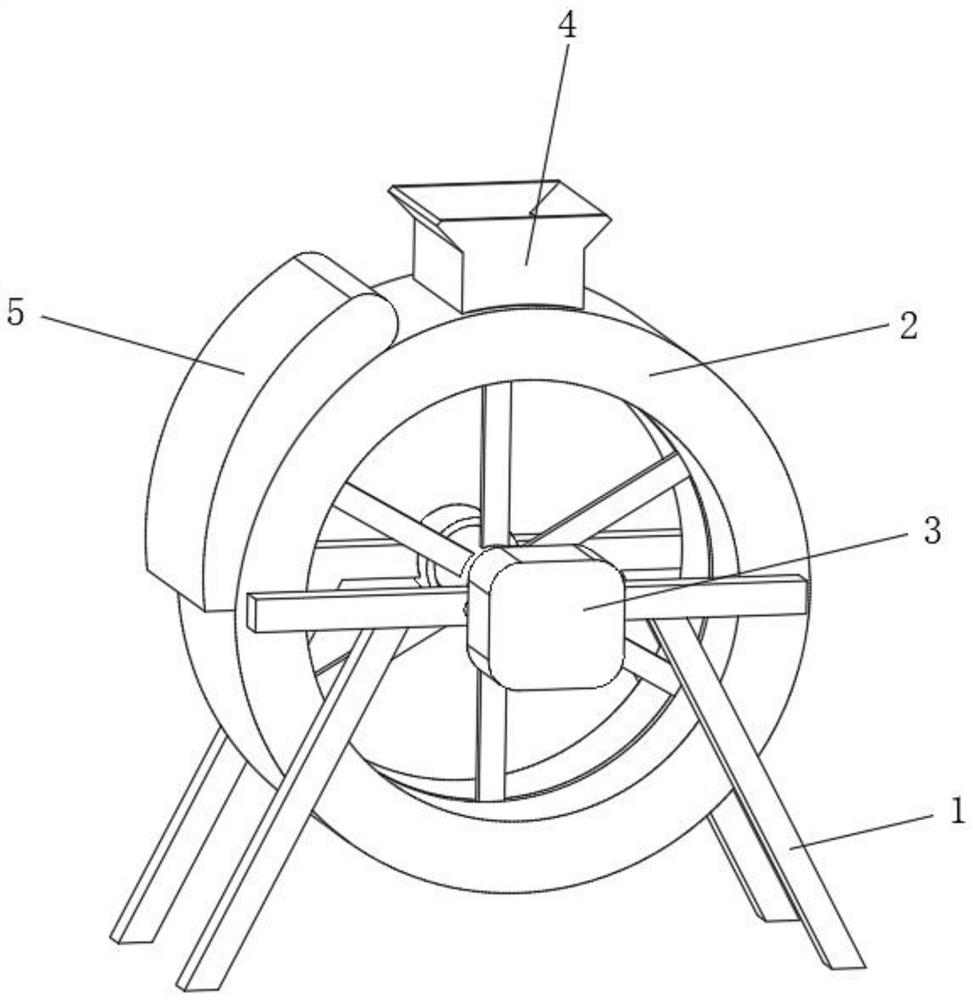

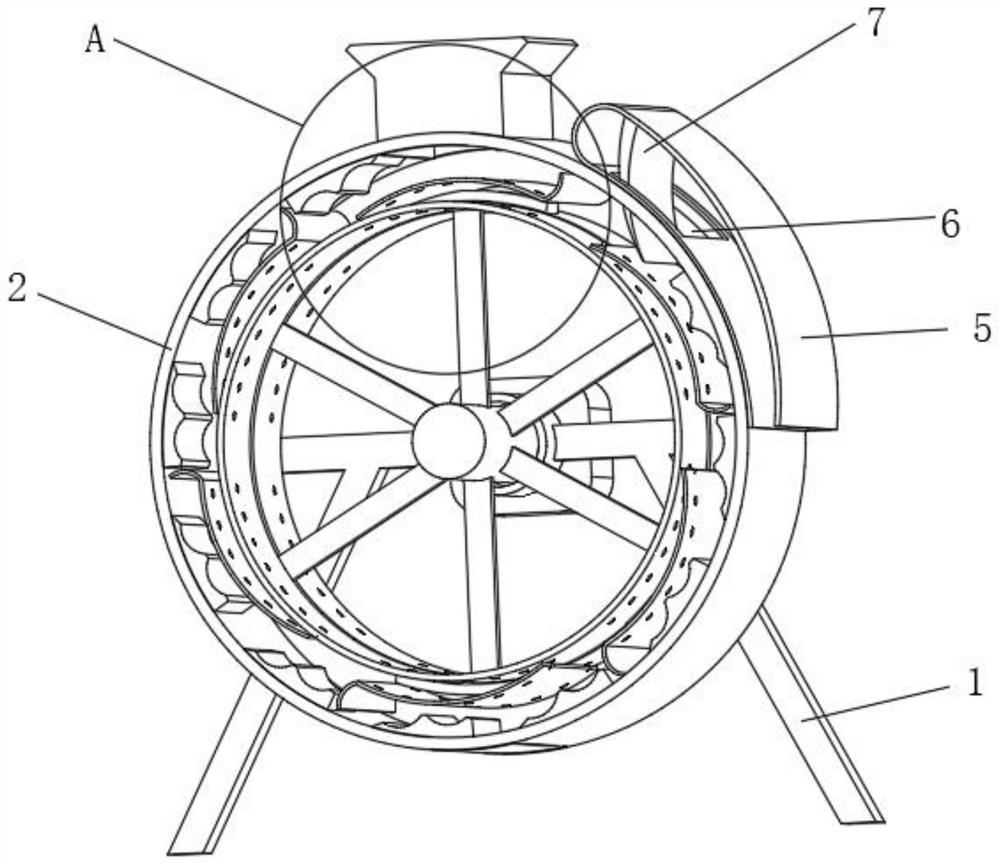

[0034] Such as Figure 1-4 As shown, the present invention provides a technical solution: a building aggregate separation and processing device, including a support frame 1, a separation roller 2 is rotatably connected to the middle position of the top of the support frame 1, and a driver 3 is fixedly connected to the middle position of the back of the support frame 1 The middle position of the top of the separation drum 2 is provided with a feed inlet 4, the right side of the front of the separation drum 2 and the position close to the upper part is provided with a discharge cylinder 5, and the position on the right side of the separation drum 2 and corresponding to the discharge cylinder 5 is provided with Discharge port 6, the top of discharge cylinder 5 is fixedly connected with discharge arc shovel 7, the bottom end of discharge arc shovel 7 extends to the inside of discharge port 6, and the inner side of separation drum 2 is fixedly connected with screening baffle 8, scre...

Embodiment 2

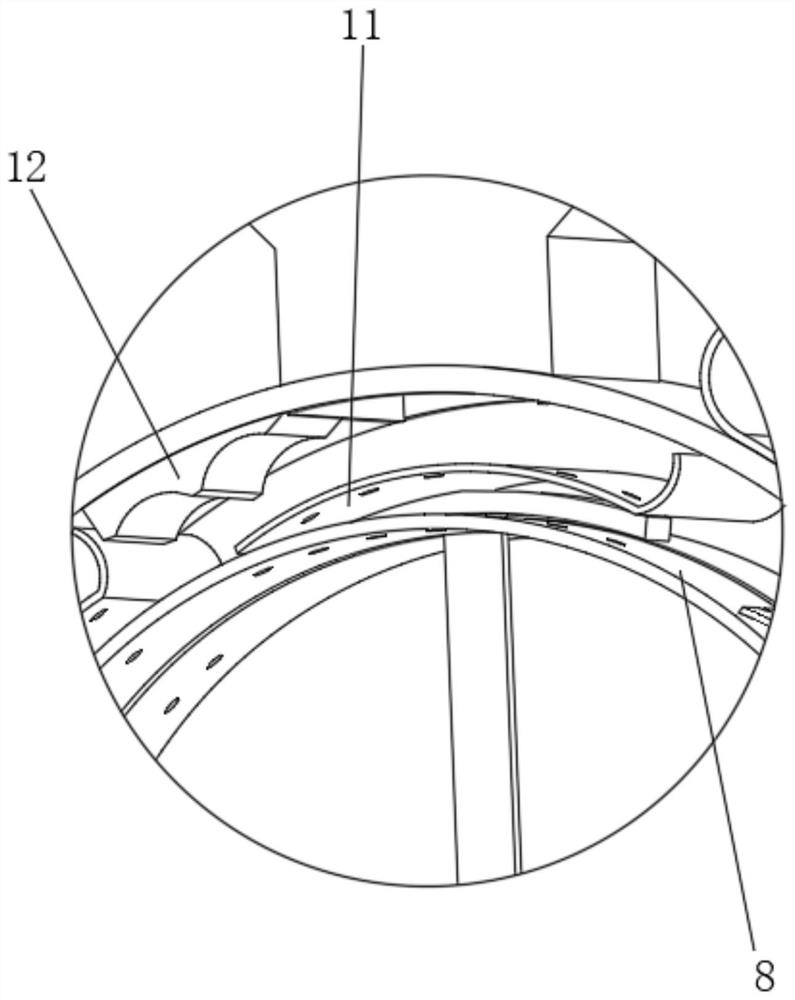

[0038] Such as Figure 5-6As shown, on the basis of Embodiment 1, the present invention provides a technical solution: a construction aggregate separation and processing device, the scraping separation mechanism 11 includes a shovel sieve plate 111, and one end of the bottom of the shovel sieve plate 111 is fixedly connected There is a supporting bottom plate 112, the bottom of which is fixedly connected with the transmission slider 10, and the end of the shoveling sieve plate 111 away from the supporting bottom plate 112 is fixedly connected with a limiting arc plate 113.

[0039] The surface of the top of the support base plate 112 is evenly fixedly connected with guide pins 114, and the surface of the shovel sieve plate 111 is uniformly provided with dredging holes 115, and each guide pin 114 is correspondingly arranged with the corresponding dredging hole 115, and the limit arc The inside of the plate 113 is correspondingly provided with a storage air guide plate 116 . Wi...

Embodiment 3

[0043] Such as Figure 7 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: a construction aggregate separation and processing device, the separation and cooperation mechanism 12 includes a booster plug plate 121, the top of the booster plug plate 121 It is fixedly connected with the separation drum 2, and the inside of the booster plug plate 121 near the bottom is rotatably connected with a damping roller 122, and the bottom of the damping roller 122 is fixedly connected with a cover elastic plate 123, and the inner surface of the cover elastic plate 123 is connected to the limit arc. Plates 113 are provided correspondingly. Increase the fluidity of the aggregate and ensure that each surface of the aggregate can be cleaned and separated.

[0044] A movable comb 124 is connected to the left side of the bottom of the pressurized plug 121 rotatably, and the surface of the damping roller 122 is evenly and fixedly connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com