Central hole forming device for blank drilling for industrial part machining

A technology of parts processing and blank parts, which is applied in the field of drilling devices, can solve problems such as time-consuming and laborious, and achieve the effects of convenient operation, stable steel rods, and accurate drilling positions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

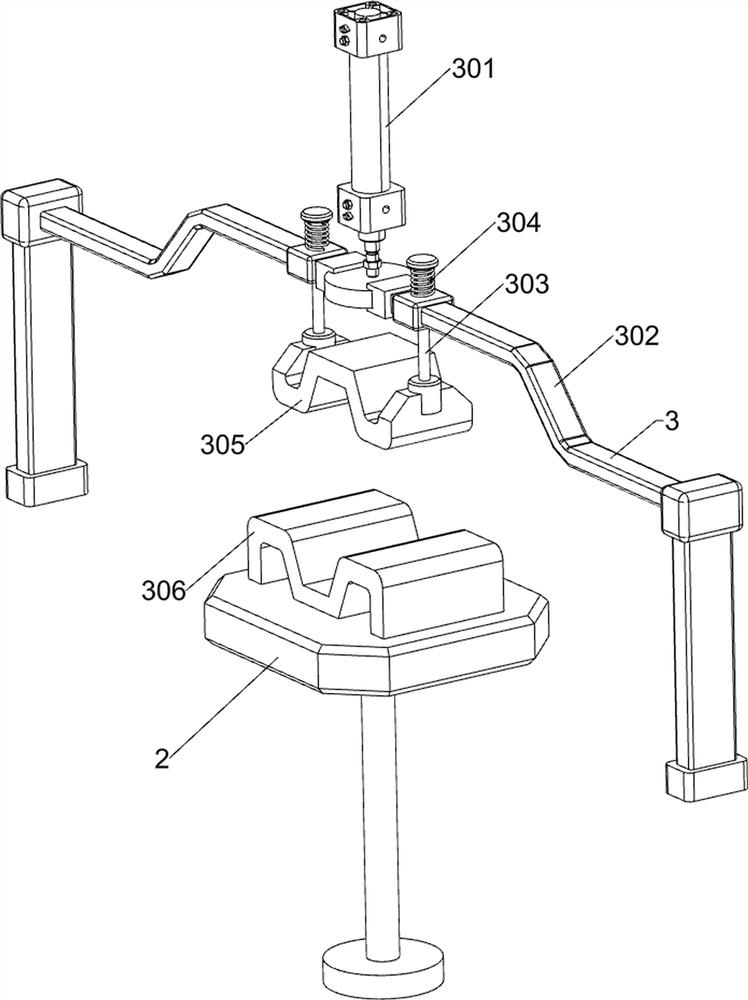

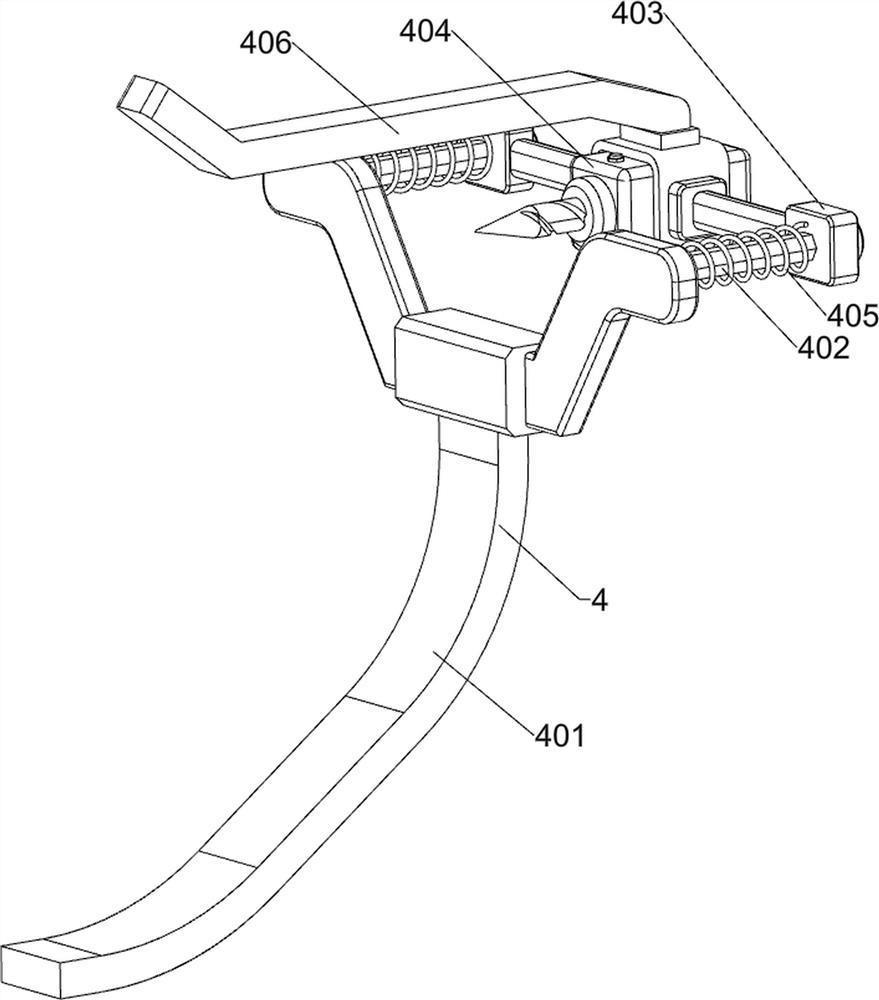

[0029] A central hole opening device for drilling blanks for industrial parts processing, such as figure 1 , figure 2 , image 3 and Figure 4 As shown, it includes a base 1, a support frame 2, a pressing assembly 3 and an opening assembly 4. The upper middle part of the base 1 is rotatably provided with a supporting frame 2, and the upper middle part of the base 1 is provided with a pressing assembly 3. The upper right side of the base 1 A hole assembly 4 is provided on the side.

[0030] The compression assembly 3 includes a cylinder 301, a first movable frame 302, a first slide bar 303, a first spring 304, a first pressing plate 305 and a shelf 306, the middle side of the top of the base 1 is provided with a cylinder 301, and the telescopic rod of the cylinder 301 The first movable frame 302 is provided on the top, and the first movable frame 302 is slidingly matched with the base 1. The front and rear sides of the first movable frame 302 are slidably provided with a fi...

Embodiment 2

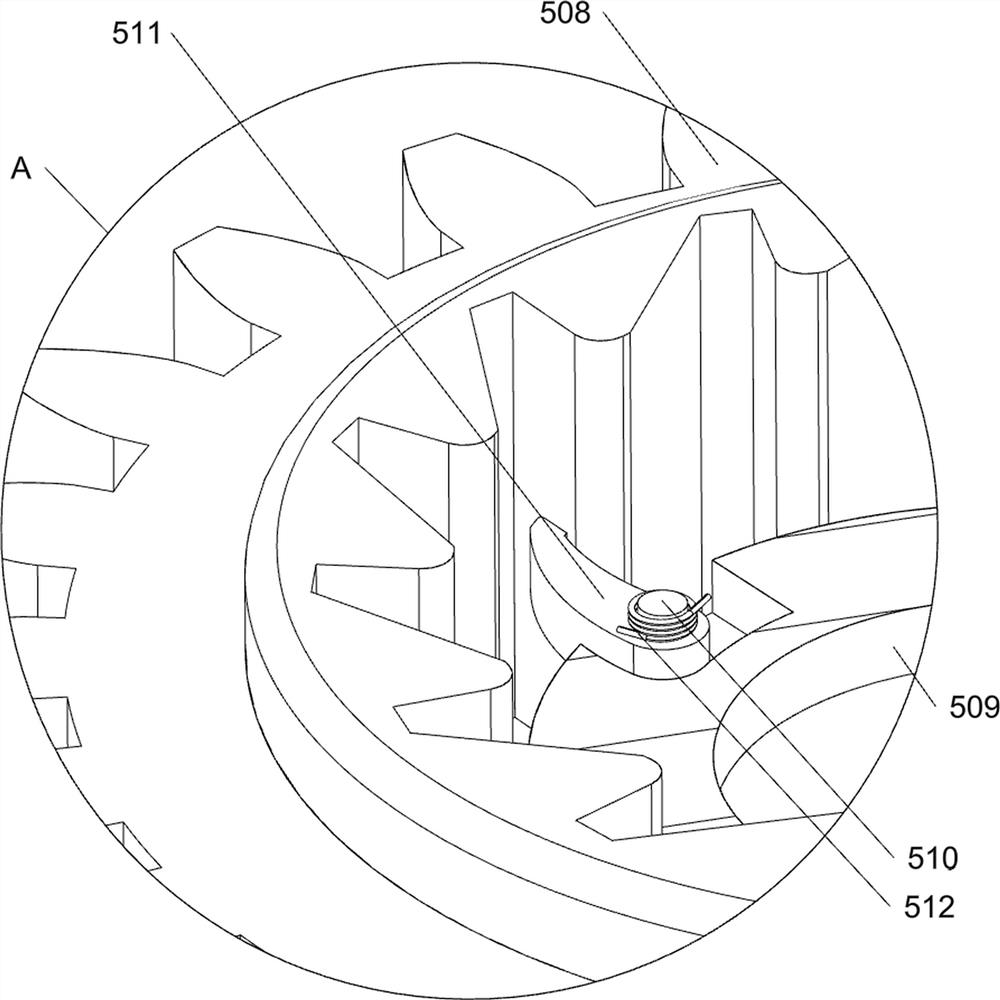

[0034] On the basis of Example 1, such as Figure 5 , Figure 6 , Figure 7 , Figure 8 and Figure 9 As shown, a rotating assembly 5 is also included, and the rotating assembly 5 includes a second bracket 501, a second guide rod 502, a third spring 503, a third movable frame 504, a first pressing rod 505, a rack 506, a bearing 507, The first toothed turntable 508, the first turntable 509, the pole 510, the pawl 511 and the torsion spring 512, the front side of the base 1 is symmetrically provided with two second brackets 501, and the top of the second bracket 501 on the same side is provided with There are second guide rods 502, and a third movable frame 504 is arranged in a symmetrical sliding manner between the second guide rods 502. Two third springs 503 are connected between the outside of the third movable frame 504 and the second bracket 501. The springs 503 are respectively sleeved on the second guide rod 502, and the lower part of the front side of the second mova...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com