Improved numerical control lathe

A numerical control lathe and an improved technology, applied in the field of numerical control lathes, can solve the problems such as the inability to clean and collect iron scraps, and achieve the effects of improving self-cleaning efficiency, increasing efficiency, and improving resilience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

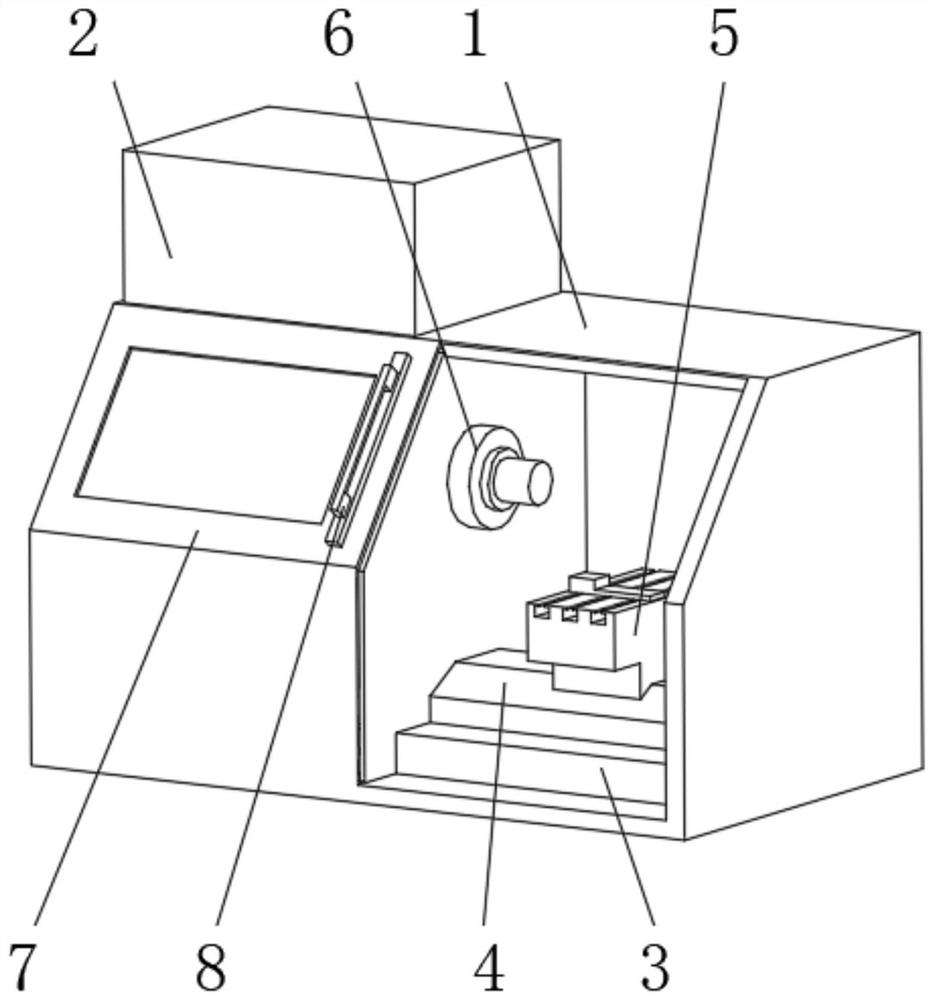

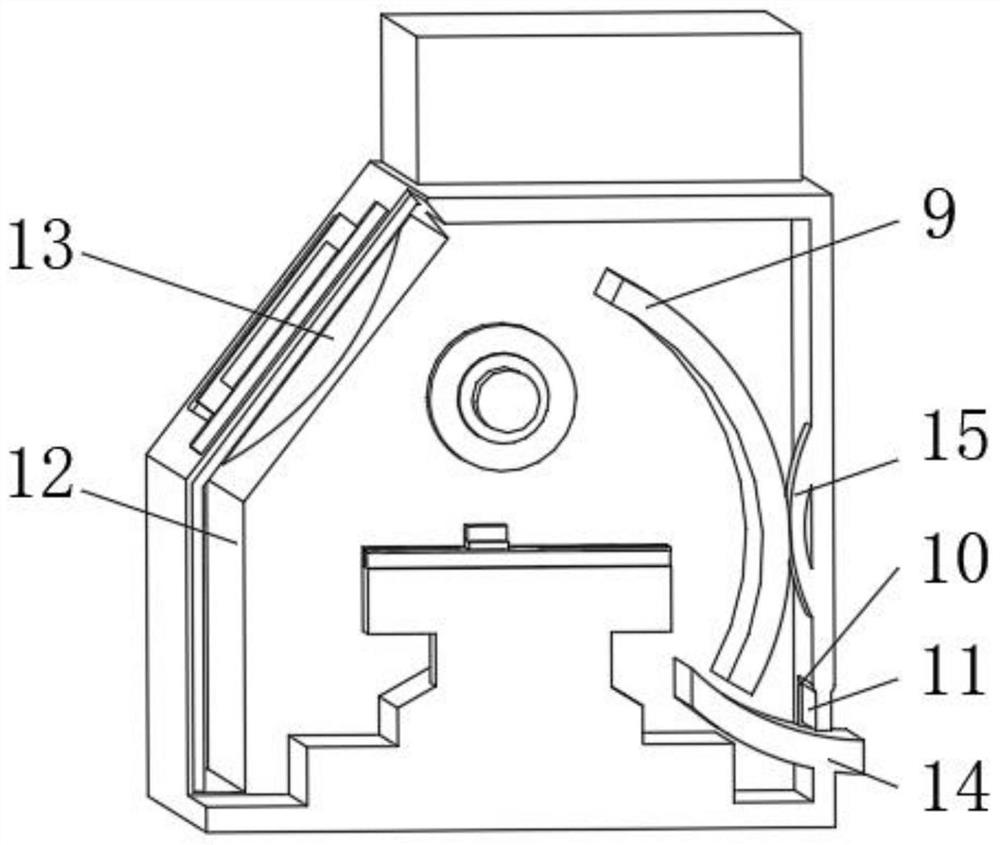

[0029] see Figure 1-3 , the present invention provides a technical solution: an improved numerical control lathe, comprising a housing 1, the top of the housing 1 is fixedly connected with a control frame 2, the inner bottom of the housing 1 is fixedly connected with a base 3, and the base 3 is away from the side of the housing 1 Fixedly connected with a fixed slider 4, the side of the fixed slider 4 away from the base 3 is slidably connected with a knife holder 5, the inner wall of the casing 1 is equipped with a clamp 6, and one side of the casing 1 is slidably connected with a sliding door 7, and the sliding door 7 One side is fixedly connected with a door handle 8, the inner wall of the shell 1 is equipped with a magnetic device 9, the side of the shell 1 near the magnetic device 9 is provided with a material intake 10, and one side of the material intake 10 is rotatably connected with a baffle plate 11.

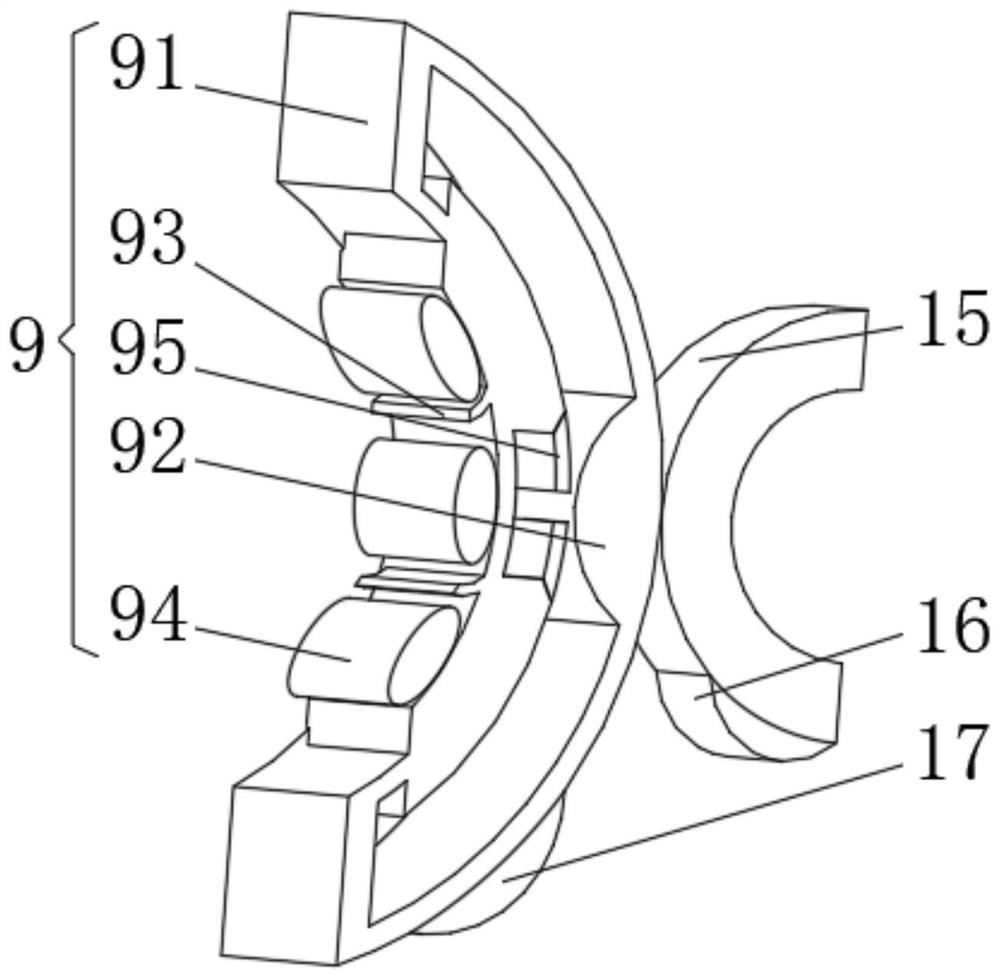

[0030] The magnetic device 9 includes an arc-shaped frame 91, an e...

Embodiment 2

[0034] see Figure 1-4, the present invention provides a technical solution: on the basis of Embodiment 1, a rectangular slot 12 is provided on the side of the housing 1 close to the sliding door 7, and an ejection device 13 is installed on the side of the sliding door 7 close to the rectangular slot 12, and the ejection device 13 includes an ejection frame 131, one side of the ejection frame 131 is fixedly connected with the sliding door 7, the inside of the ejection frame 131 is fixedly connected with a rotating shaft 132, and the outer side of the rotating shaft 132 is provided with a rotating plate 133, and one side of the rotating plate 133 is fixed Connected with a spring 134, the end of the spring 134 away from the rotating plate 133 is fixedly connected with the ejection frame 131, the top of the ejection frame 131 is fixedly connected with an elastic pull cord 135, and one end of the elastic pull cord 135 is fixedly connected with a slider 136, the slider 136 One side...

Embodiment 3

[0039] see Figure 1-5 , the present invention provides a technical solution: on the basis of Embodiment 2, a collection device 14 is installed in the inside of the housing 1 close to the feeding port 10, the collection device 14 includes a collection frame 141, and the interior of the collection frame 141 is fixedly connected with Squeeze the air bag 142, the inner wall of the collection frame 141 is slidably connected with a semicircle block 143, one side of the semicircle block 143 is symmetrically equipped with an elastic rod 144, and the end of the elastic rod 144 away from the semicircle block 143 is fixedly connected with a metal ball 145.

[0040] When in use, the iron filings collected intensively fall onto the collection frame 141, and the gravity of the iron filings accumulated on the collection frame 141 increases continuously. The expansion volume increases, and the semicircular block 143 is pushed outward. At this time, the semicircular block 143 shakes to drive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com