Large-area aluminum single crystal film and preparation method and application thereof

A single-crystal thin film, large-area technology, applied in single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems of high dislocation density, twinning, XRD diffraction peak width, etc., and achieve a clear and sharp interface. The effect of excellent optical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] One aspect of the embodiments of the present invention provides a method for preparing a large-area aluminum single crystal thin film, which includes:

[0031] The Si(111) substrate is sequentially subjected to organic cleaning, RCA1 cleaning, RCA2 cleaning, piranha solution cleaning and HF cleaning to obtain a pretreated Si(111) substrate;

[0032] And, under vacuum conditions, the pretreated Si(111) substrate is placed in a molecular beam epitaxy device for surface treatment at 750-800°C, and the surface of the Si(111) substrate is treated by molecular beam epitaxy technology Growing aluminum single crystal thin films to obtain large area aluminum single crystal thin films, wherein the process conditions adopted by the molecular beam epitaxy technology include: the temperature of the cold nozzle Al source is 1000-1235 °C, and the Al deposition rate is

[0033] In some more specific embodiments, the preparation method includes:

[0034]The pretreated Si(111) substra...

Embodiment 1

[0073] Commercial 2inch Si(111) substrates (R>10000Ω·cm) were sequentially cleaned by organic cleaning, RCA1, RCA2, piranha cleaning and HF cleaning, and then immediately put into the sample chamber of the nano-vacuum interconnection experiment station, and then introduced into the sample chamber through the ultra-high vacuum pipeline Molecular beam epitaxy (MBE), low-temperature degassing for half an hour, slowly heated to 750°C for 0.5h, clear Si(111) can be seen through high-energy electron diffraction (reflection high energy electron diffraction, RHEED) 7*7 surface, then cool down naturally, and at the same time raise the temperature of the Al source of the cold nozzle to 1000°C, at this time the Al deposition rate is about Immediately after cooling down to 100°C, an Al single crystal thin film of about 100nm is grown, which is denoted as Si(111) / Al single crystal thin film.

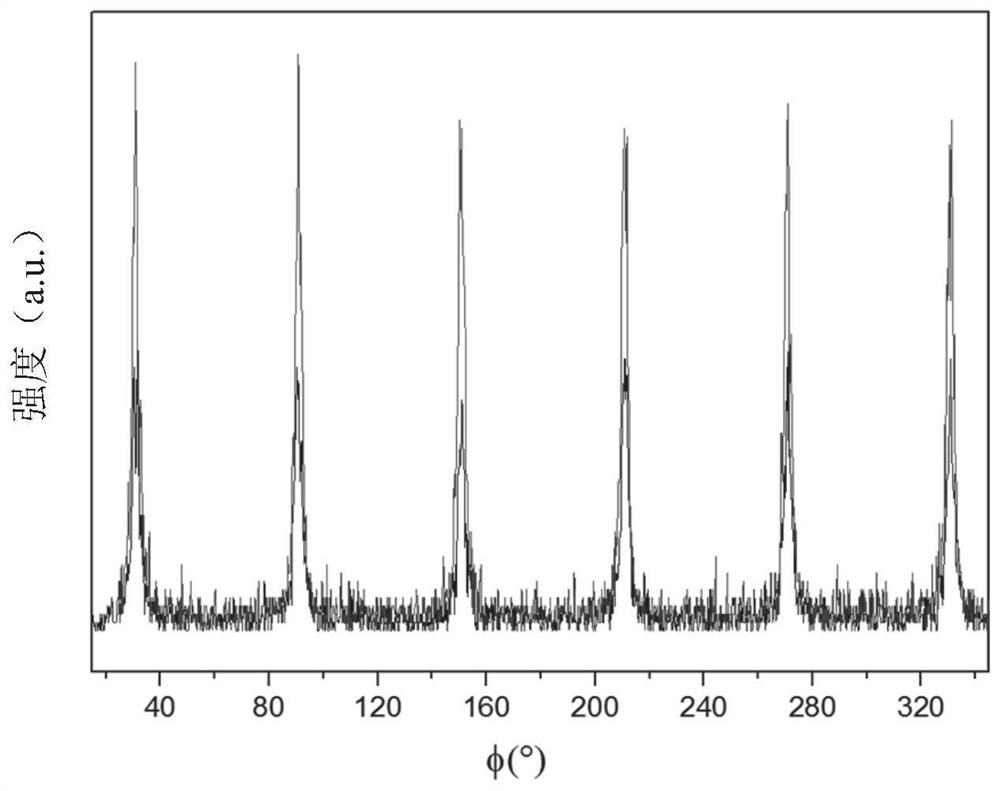

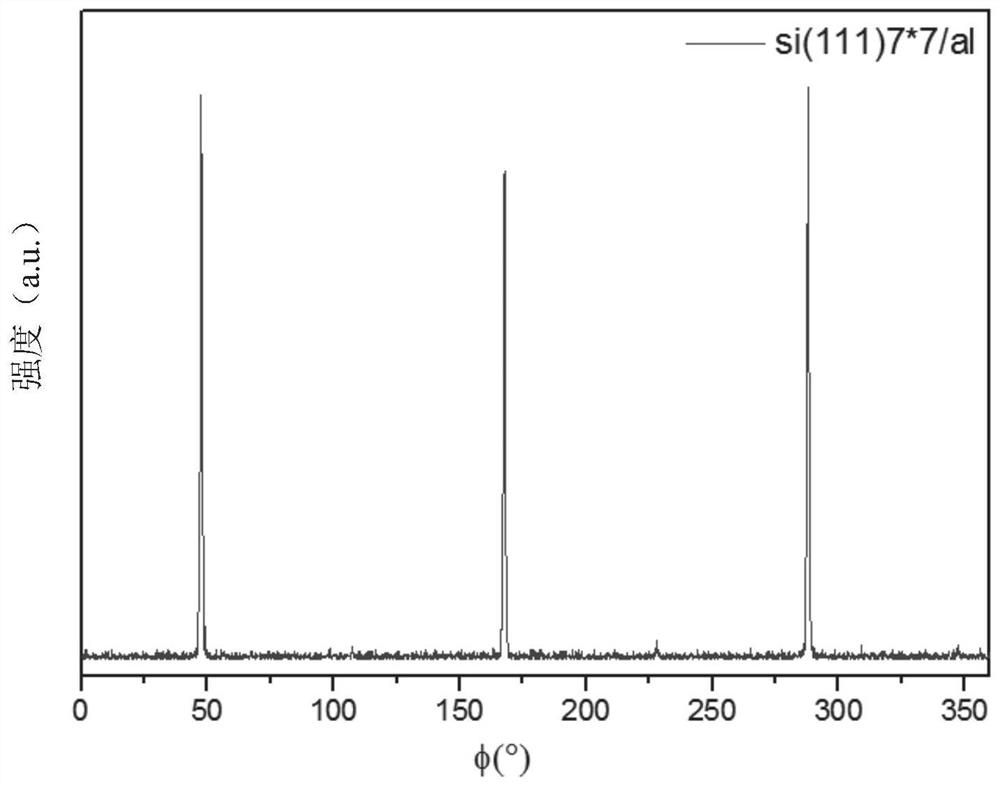

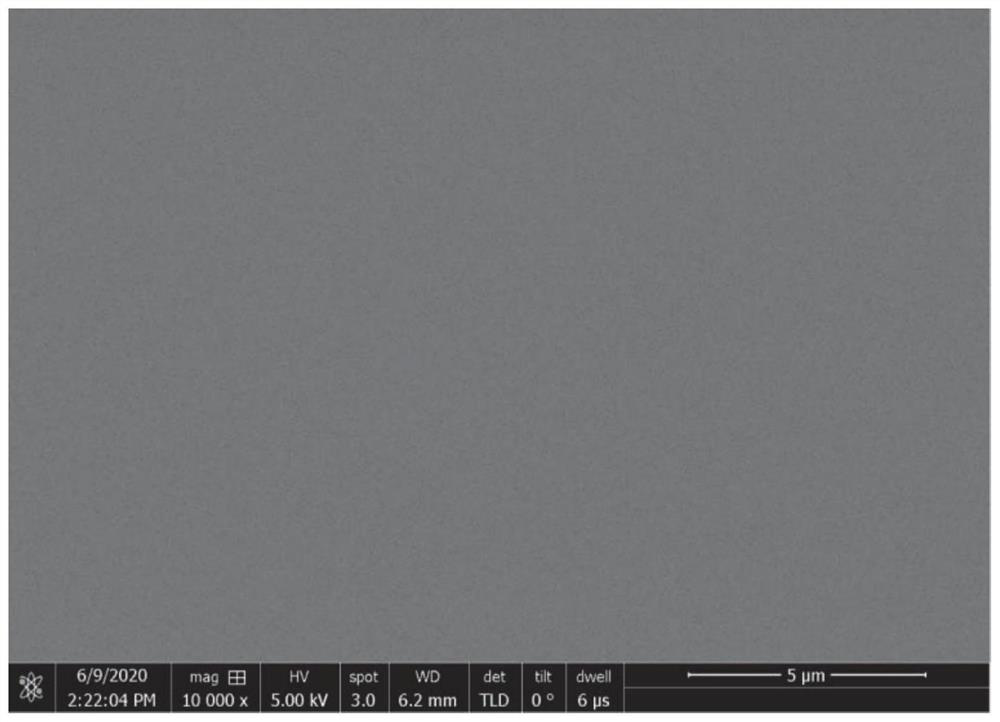

[0074] Performance characterization: The XRD spectrum of the Si(111) / Al single crystal thin film...

Embodiment 2

[0076] Commercial 2inch Si(111) substrates (R>10000Ω·cm) were sequentially cleaned by organic cleaning, RCA1, RCA2, piranha cleaning and HF cleaning, and then immediately put into the sample chamber of the nano-vacuum interconnection experiment station, and then introduced into the sample chamber through the ultra-high vacuum pipeline Molecular beam epitaxy (MBE), low-temperature degassing for half an hour, slowly heated to 770 ° C for 0.5 h, clear Si(111) can be seen through high-energy electron diffraction (reflection high energy electron diffraction, RHEED) 7*7 surface, then cool down naturally, and at the same time raise the temperature of the Al source of the cold nozzle to 1200°C, at this time the Al deposition rate is about Immediately after cooling down to 28°C, an Al single crystal thin film of about 100nm is grown, which is denoted as Si(111) / Al single crystal thin film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com