Direct current power generation cloth

A DC power generation and electrode technology, applied in friction generators, fabrics, textiles, etc., can solve the problems of inconvenient application in the field of flexible electronics, and achieve the effects of simple structure, simple production process, and wide source of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

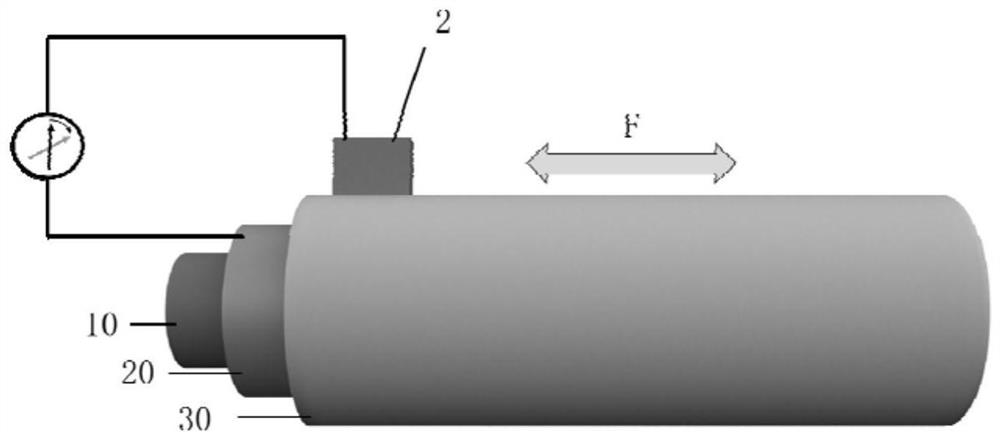

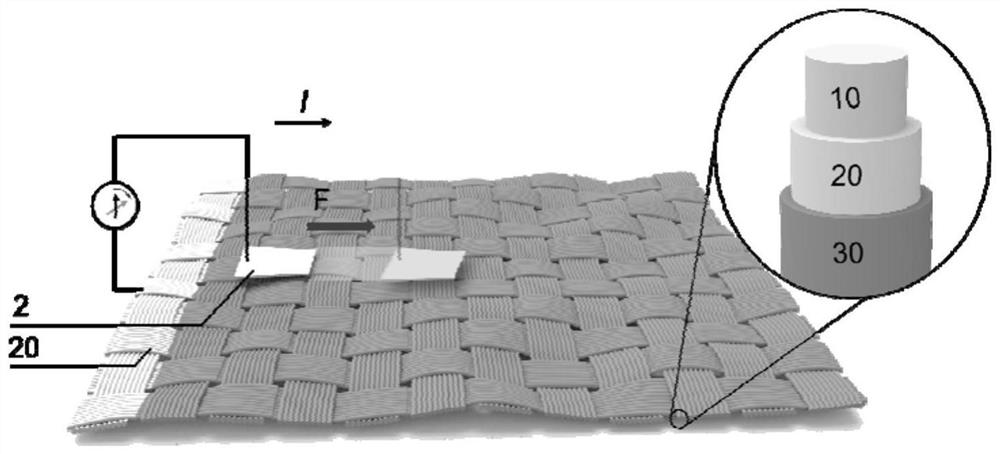

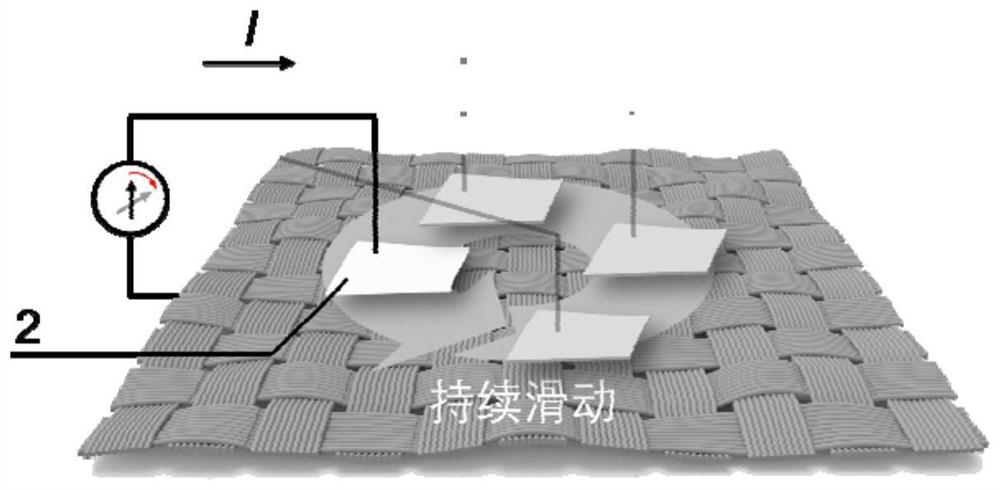

[0024] Structural reference of DC power distribution provided by the present invention figure 1 with figure 2 , the DC power generation fabric includes a fiber fabric 1 and a sliding electrification layer 2, wherein the fiber fabric 1 includes laminated fibers 10, an electrode metal layer 20 and a semiconductor layer 30, wherein the electrode metal layer 20 and the semiconductor layer 30 form an ohmic touch. The material of the sliding electrification layer 2 is a metal that forms a Schottky junction with the semiconductor layer 30, and the sliding electrification layer 2 slides on the surface of the semiconductor layer 30 of the fiber fabric, which can gene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap