Conductivity monitoring device for silicon cell cleaning liquid medicine

A monitoring device and conductivity technology, which is applied in the field of conductivity monitoring device for silicon battery cleaning liquid, can solve problems such as errors, low accuracy of data results, and clean detection probes, so as to achieve low energy consumption of equipment, avoid adhesion of impurities and The effects of liquid residue and accurate monitoring results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

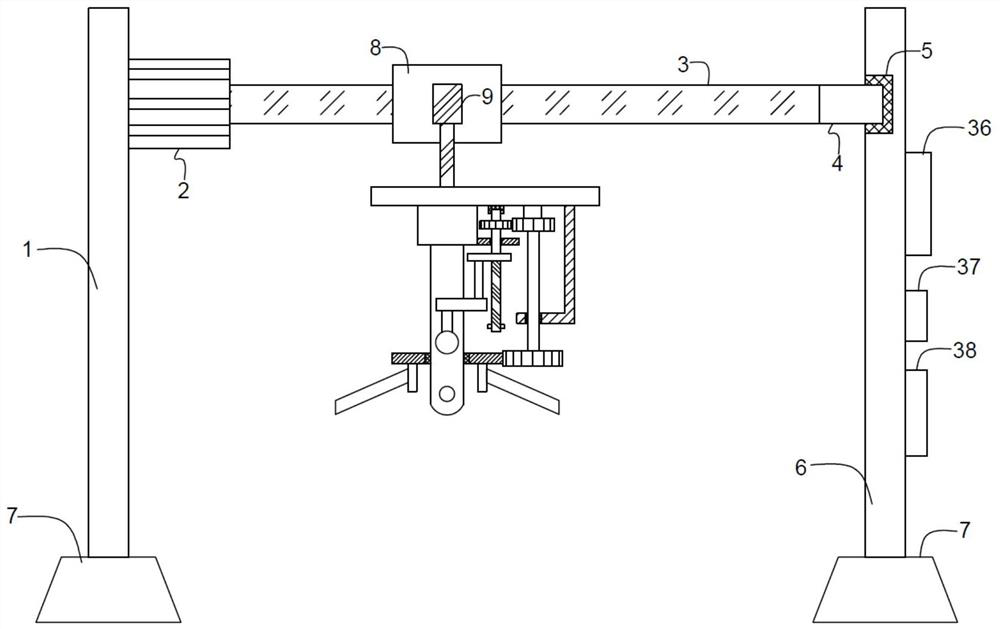

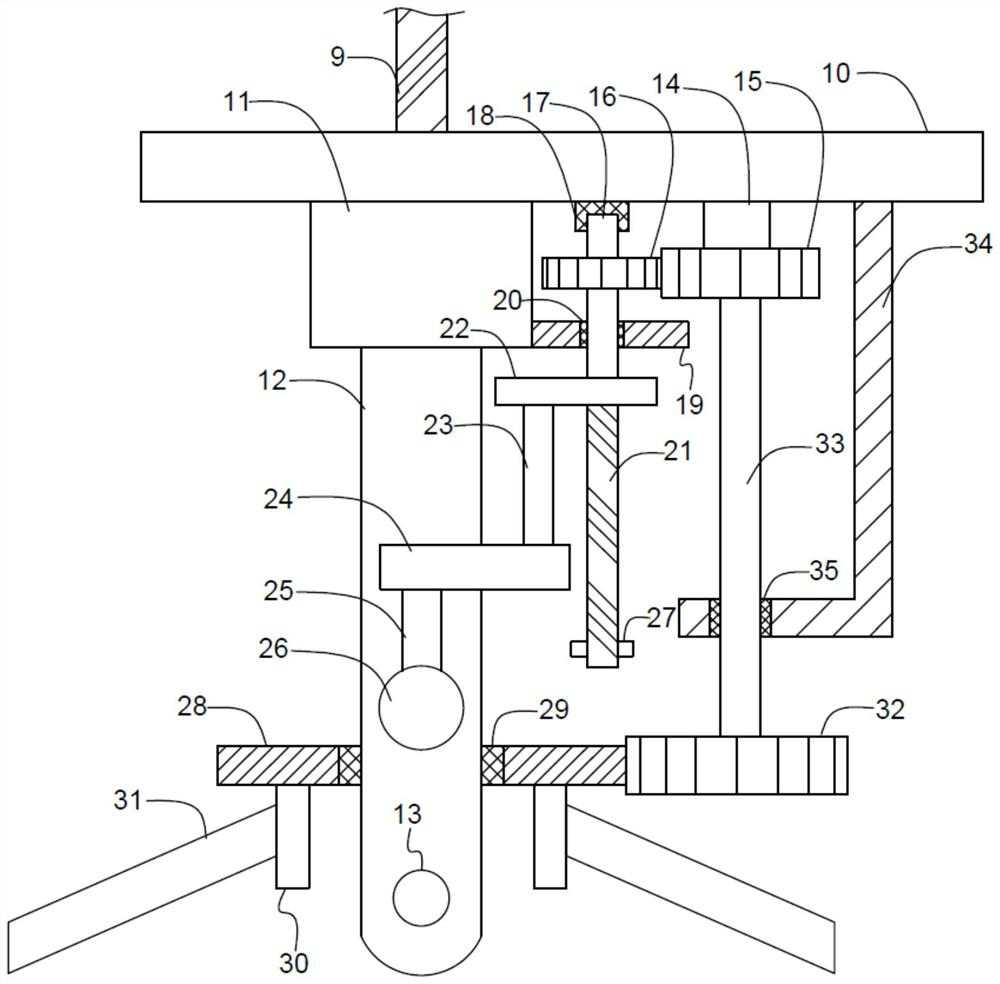

[0027] see Figure 1 to Figure 2 , the present invention provides a technical solution:

[0028] A conductivity monitoring device for silicon battery cleaning liquid, comprising:

[0029] The first support column 1, the first support column 1 is fixedly provided with a rotary motor-2, the rotary motor-2 is a motor that can rotate in both directions, and the output end of the rotary motor-2 is fixedly provided with a lead screw-3, a lead screw-3 One end away from the rotary motor 2 is fixedly provided with a connecting rod 4, the connecting rod 4 is hingedly arranged in the bearing seat 5, the bearing seat 5 is embedded in the second support column 6, and the lead screw 3 is movable. There is a nut-8, when the lead screw-3 rotates, the nut-8 will move along the lead screw-3;

[0030] Cylinder 9, cylinder 9 is fixedly arranged on the side of nut one 8, the output end of cylinder 9 is fixedly provided with mounting plate 10, and the side of mounting plate 10 away from cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com