Lead bonding quality prediction control method based on machine learning

A quality prediction and wire bonding technology, applied in the field of wire bonding quality prediction control based on machine learning, can solve the inevitable quality and efficiency problems, slow detection feedback, bonding quality decline and other problems, to achieve quality prediction and The effect of process optimization, improving product yield and reducing inspection cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to better understand the above-mentioned technical solution, the above-mentioned technical solution will be described in detail below in conjunction with the accompanying drawings and specific implementation methods.

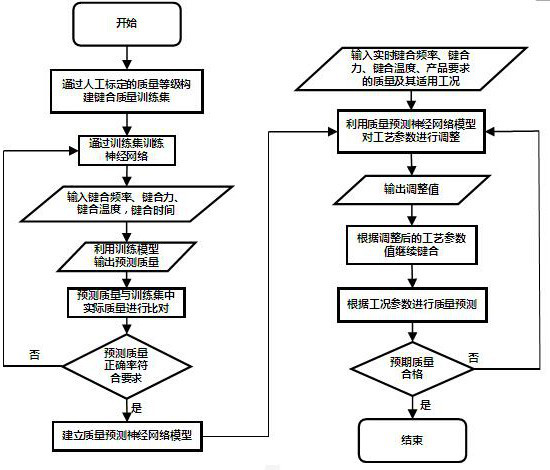

[0031] A kind of wire bonding quality predictive control method based on machine learning provided by the present invention, see figure 1 , including the following steps:

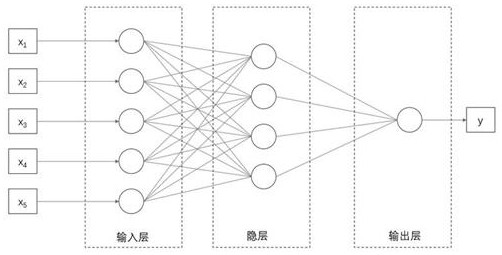

[0032] Step S1: selecting several key process parameters of wire bonding as key influencing factors of wire bonding, and constructing a quality prediction neural network model based on the key influencing factors;

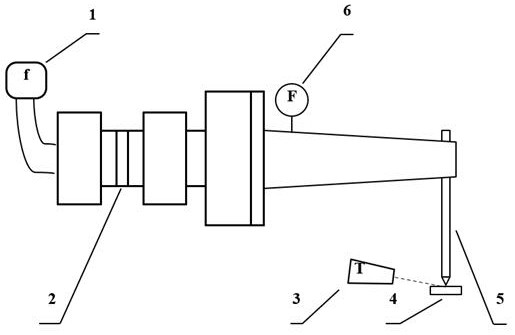

[0033] Step S2: Collect and obtain the real-time process parameters corresponding to the key influencing factors when the wire bonding machine is working;

[0034] Step S3: According to the real-time process parameters, use the quality prediction neural network model to predict the quality of wire bonding to obtain a quality prediction result; adjust the process p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com