A manual and automatic switchable floor scrubber scraper lifting mechanism

A manual, automatic, switchable technology, which is applied in the direction of cleaning carpets, cleaning machines, cleaning floors, etc., can solve the problems of limited application range, low practicability, and low environmental protection performance, and achieve wide application range, improved practicability, and environmental protection performance. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

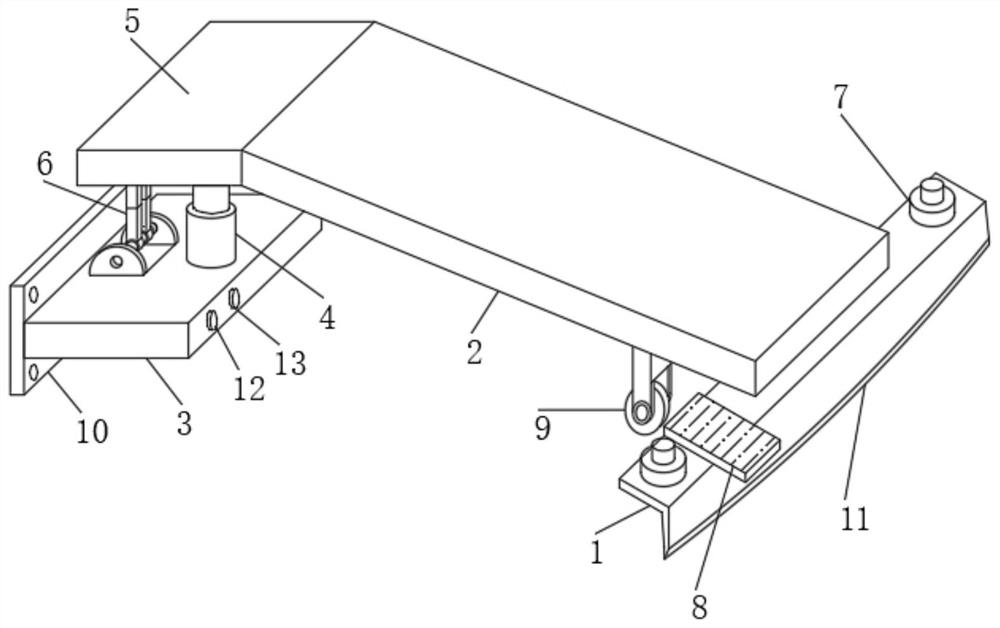

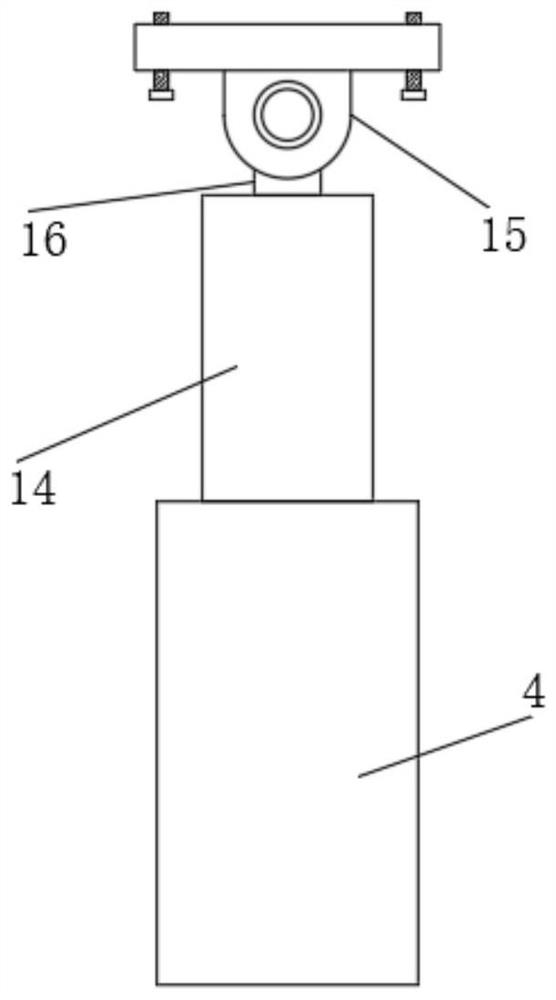

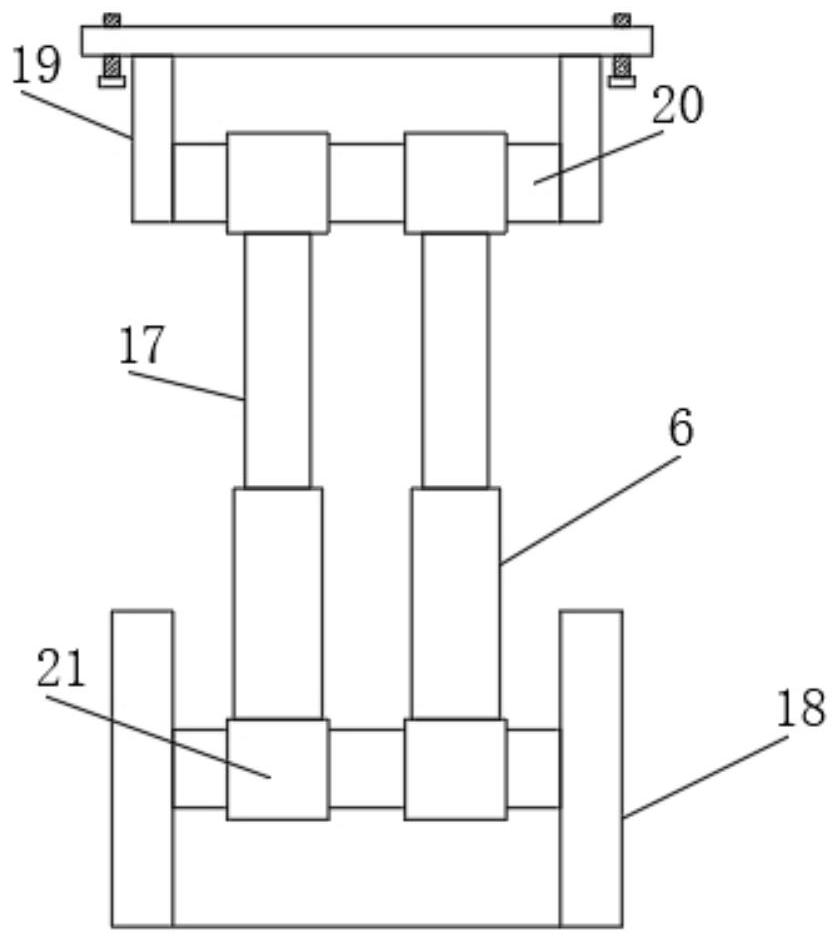

[0033] Firstly, it is installed at the rear end of the floor washer through the fixed mounting plate 10. The rising button 12 and the falling button 13 at the right end of the support plate 3 can be directly pressed to automatically control the overall lifting of the scraper 1 and the lifting plate 2. The hydraulic cylinder 4 controls the lifting of the hydraulic column 14. The connecting plate 5 is stably supported through the connecting column 16 and the rotating shaft seat 15. The hydraulic sleeve 6 and the hydraulic rod 17 are telescopic supported at the left end of the connecting plate 5, The rotating shaft rod 20 and the bearing ring 21 connected at the bottom and top of the hydraulic sleeve 6 and the hydraulic rod 17 rotate and support, the rotating shaft rod 20, the lower fixing frame 18 and the upper fixing frame 19 are fixedly installed between the support plate 3 and the connecting plate 5, the auxiliary pulley 9 is fixed at the bottom of the lifting plate 2 for auxilia...

example 2

[0035] Firstly, it is installed at the rear end of the floor washer through the fixed mounting plate 10. Through the fixed plate 8 fixed at the front end of the top of the scraper 1, it is efficient and directly controlled by manual pressing or lifting to control the overall lifting of the scraper 1 and the lifting plate 2, the hydraulic cylinder 4 and the hydraulic column 14 rise and fall, the connecting plate 5 is stably supported through the connecting column 16 and the rotating shaft seat 15, and the hydraulic sleeve 6 and the hydraulic rod 17 are telescopic supported at the left end of the connecting plate 5, The rotating shaft rod 20 and the bearing ring 21 connected at the bottom and top of the hydraulic sleeve 6 and the hydraulic rod 17 rotate and support, the rotating shaft rod 20, the lower fixing frame 18 and the upper fixing frame 19 are fixedly installed between the support plate 3 and the connecting plate 5, the auxiliary pulley 9 is fixed at the bottom of the liftin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com