An automatic welding system, welding method and connection structure of welded products

A technology of automatic welding and welding methods, applied in welding equipment, metal processing equipment, metal processing, etc., can solve the problems of large dependence on manual operation, unfavorable large-scale production, and high labor cost, so as to reduce human dependence and human labor. Dependency, the effect of increasing the level of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] The embodiments of the present application disclose an automatic welding system and a welding method.

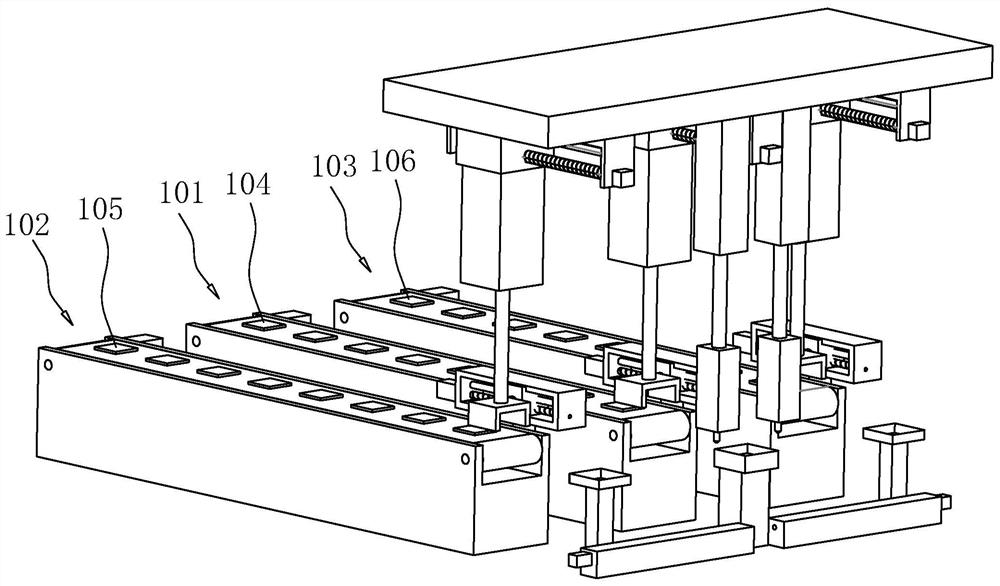

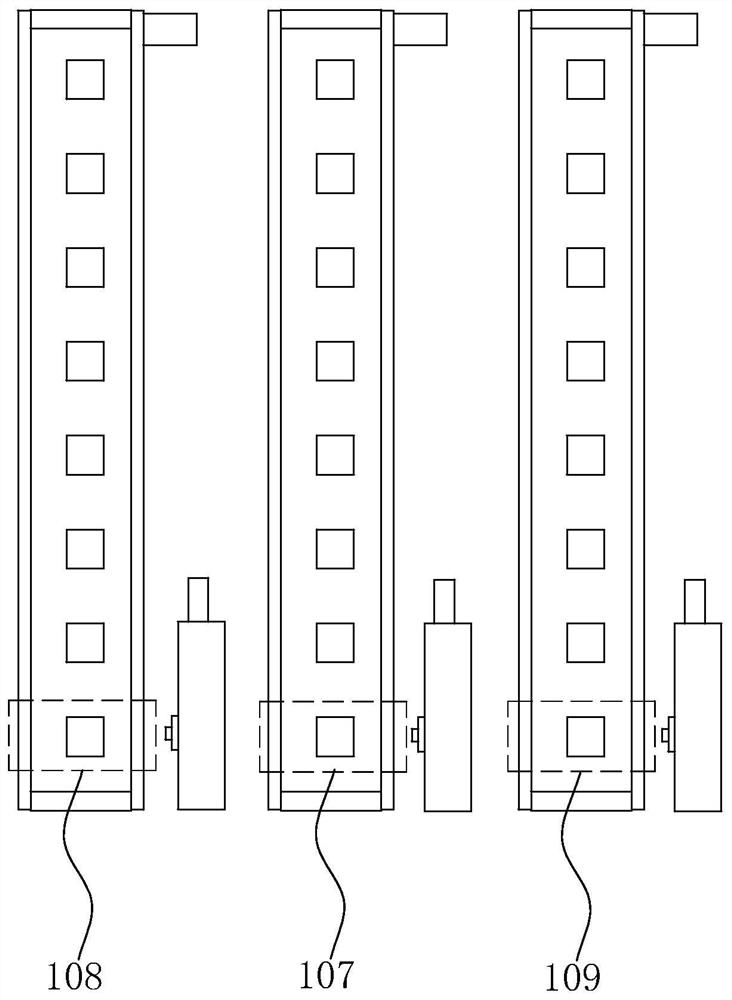

[0062] like figure 1 , 2 As shown, an automatic welding system includes a detection unit, a control unit and three parallel conveying lines, including a first transmission line 101, a second transmission line 102 is arranged on one side of the first transmission line 101, and a first transmission line 102 is arranged on the other side. Three transmission lines 103 , the first transmission line 101 , the second transmission line 102 , and the third transmission line 103 are parallel to each other and have the same structure.

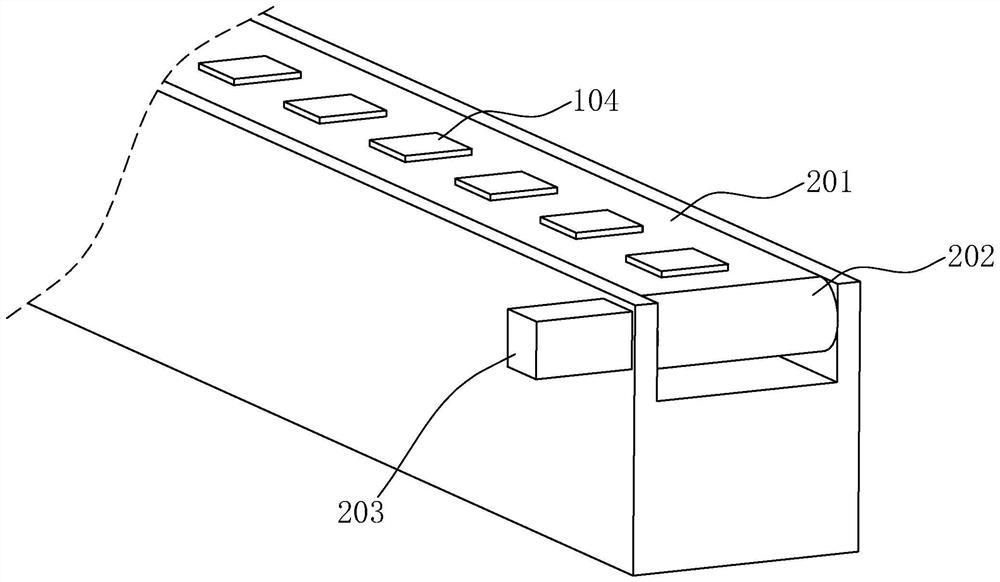

[0063] like image 3 As shown, this embodiment takes the first transmission line 101 as an example. The first transmission line 101 includes a first conveyor belt 201, and the first conveyor belt 201 is driven by two first rollers 202. The drive motor 203 is controlled by the control unit, including speed control, on or off control.

[0064] ...

Embodiment 2

[0115] The embodiment of the present application discloses a connection structure of a welded product obtained by an automatic welding system.

[0116] like Figure 10 , 11 As shown, a connection structure of a welded product obtained by an automatic welding system includes pins 902 arranged on the atomizer housing 901, the direction of the pins 902 is parallel to the length direction of the atomizer housing 901, and the first welding part The plane where 104 is located is parallel to the pin 902, a contact point 904 is provided on the lower surface of the first welding part 104, and a snap-fit assembly 903 is provided between the contact point 904 and the pin 902, so that the first welding part 104 is connected to the atomizer. The device housings 901 can be snap-connected through a snap-fit assembly 903 .

[0117] The first welding part 104 , the second welding part 105 and the third welding part 106 are welded products obtained by the welding process as described in Emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com