Testing device suitable for parts of electric tool

A technology of testing equipment and electric tools, which is applied in the testing of mechanical components, testing of machine/structural components, workpiece clamping devices, etc., can solve the problem of stuck or inflexible adjustment, reduce flexibility and stability, and reduce the test area and other problems to achieve the effect of avoiding stuck or inflexible adjustment, improving flexibility and stability, and increasing flexibility and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

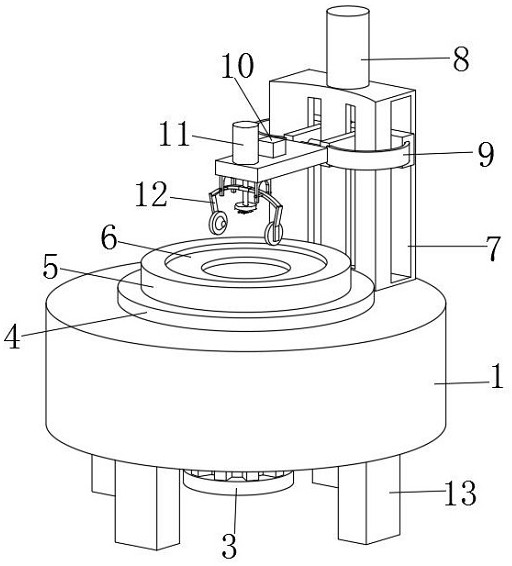

[0031]A test device suitable for power tool components such as Figure 1-2 As shown, the test body 1 is included, the upper middle part of the test body 1 is provided with a sliding groove 2, the lower end middle part of the test body 1 is fixedly connected with a motor 3, the output end of the motor 3 penetrates the test body 1 and is fixedly connected with a sliding structure 4, and the sliding The upper end of the structure 4 is fixedly connected with a storage board 5, and the middle part of the upper end of the storage board 5 is provided with a test slot 6, and the rear part of the upper end of the test body 1 is fixedly connected with a support frame 7, and the upper end of the support frame 7 is fixedly connected with a telescopic controller 8 , the output end of the No. 1 telescopic controller 8 runs through the upper end of the support frame 7 and is fixedly connected with an adjustment structure 9. The adjustment structure 9 is provided with a test controller 10 and ...

Embodiment 2

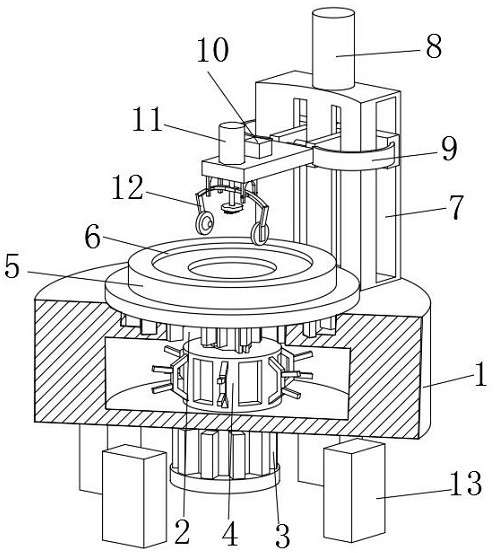

[0034] On the basis of Example 1, as Figure 3-4 As shown, a test device suitable for electric tool components includes a test body 1, a sliding groove 2 is opened in the middle of the upper end of the test body 1, a motor 3 is fixedly connected to the middle of the lower end of the test body 1, and the output end of the motor 3 runs through The test main body 1 is fixedly connected with a sliding structure 4, the upper end of the sliding structure 4 is fixedly connected with a storage board 5, the middle part of the upper end of the storage board 5 is provided with a test slot 6, and the upper end rear of the test main body 1 is fixedly connected with a support frame 7, supporting The upper end of the frame 7 is fixedly connected with a No. 1 telescopic controller 8. The output end of the No. 1 telescopic controller 8 runs through the upper end of the support frame 7 and is fixedly connected with an adjustment structure 9. The adjustment structure 9 is provided with a test con...

Embodiment 3

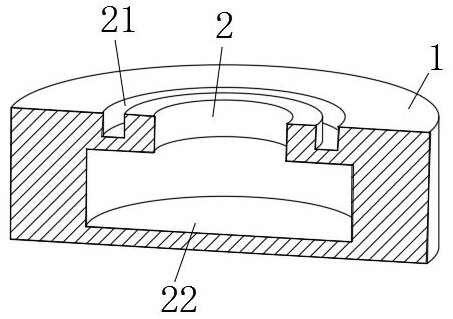

[0037] On the basis of Example 1, as Figure 5 with 6 As shown, a test device suitable for electric tool components includes a test body 1, a sliding groove 2 is opened in the middle of the upper end of the test body 1, a motor 3 is fixedly connected to the middle of the lower end of the test body 1, and the output end of the motor 3 runs through The test main body 1 is fixedly connected with a sliding structure 4, the upper end of the sliding structure 4 is fixedly connected with a storage board 5, the middle part of the upper end of the storage board 5 is provided with a test slot 6, and the upper end rear of the test main body 1 is fixedly connected with a support frame 7, supporting The upper end of the frame 7 is fixedly connected with a No. 1 telescopic controller 8. The output end of the No. 1 telescopic controller 8 runs through the upper end of the support frame 7 and is fixedly connected with an adjustment structure 9. The adjustment structure 9 is provided with a te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com