Graphene electric heating film and preparation method thereof

A graphene electric heating film and graphene technology, which is applied in the field of graphene electric heating film and its preparation, can solve the problems of high production and preparation cost, can not meet the needs of lightweight use, etc. The effect of improving the efficiency of electrothermal radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

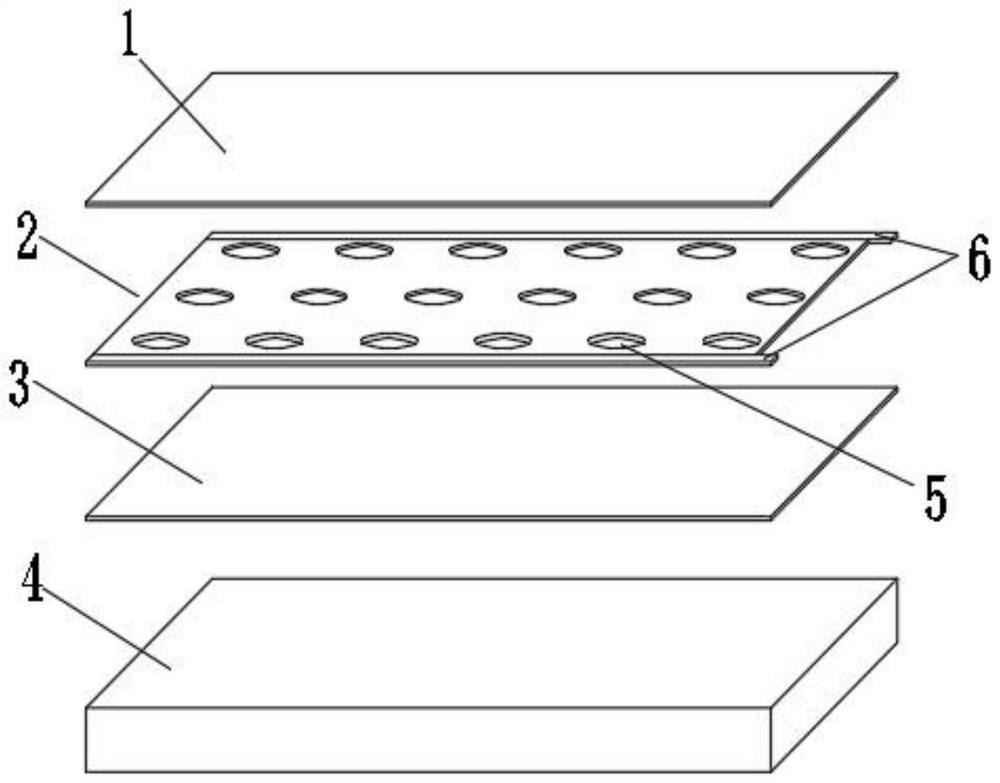

[0023] A graphene electric heating film, comprising a graphene electric heating film sequentially compounded and connected by an insulating heat-conducting layer 1, a graphene electric heating film layer 2, an insulating heat insulating layer 3 and a film-forming substrate 4, the graphene electric heating film The graphene electric heating film layer 2 is formed with a plurality of hollow holes 5, and the plurality of hollow holes 5 are evenly arranged.

[0024] Its purpose is, by forming a plurality of hollow holes on the graphene electric heating film layer, a plurality of hollow holes can be processed on a specific mold for producing the graphene electric heating film layer, thereby reducing the preparation material to a certain extent. The dosage saves the cost of production and preparation, realizes the requirement of lightweight use, and broadens the scope of actual use.

[0025] Further, the graphene electric heating film layer 2 is compositely arranged between the insu...

Embodiment 2

[0035] A graphene electric heating film, comprising a graphene electric heating film sequentially compounded and connected by an insulating heat-conducting layer 1, a graphene electric heating film layer 2, an insulating heat insulating layer 3 and a film-forming substrate 4, the graphene electric heating film The graphene electric heating film layer 2 is formed with a plurality of hollow holes 5, and the plurality of hollow holes 5 are evenly arranged.

[0036] Its purpose is, by forming a plurality of hollow holes on the graphene electric heating film layer, a plurality of hollow holes can be processed on a specific mold for producing the graphene electric heating film layer, thereby reducing the preparation material to a certain extent. The dosage saves the cost of production and preparation, realizes the requirement of lightweight use, and broadens the scope of actual use.

[0037] Further, the graphene electric heating film layer 2 is compositely arranged between the insu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com