A kind of method for reducing styrene tar viscosity and improving fluidity

A technology for ethylene tar and styrene, applied in the fields of improving fluidity and reducing viscosity of styrene tar, can solve the problems of difficult outsourcing, blocked pipelines, inconvenient transportation, etc., and achieves low economic added value, smooth loading and unloading vehicles, and easy access to Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

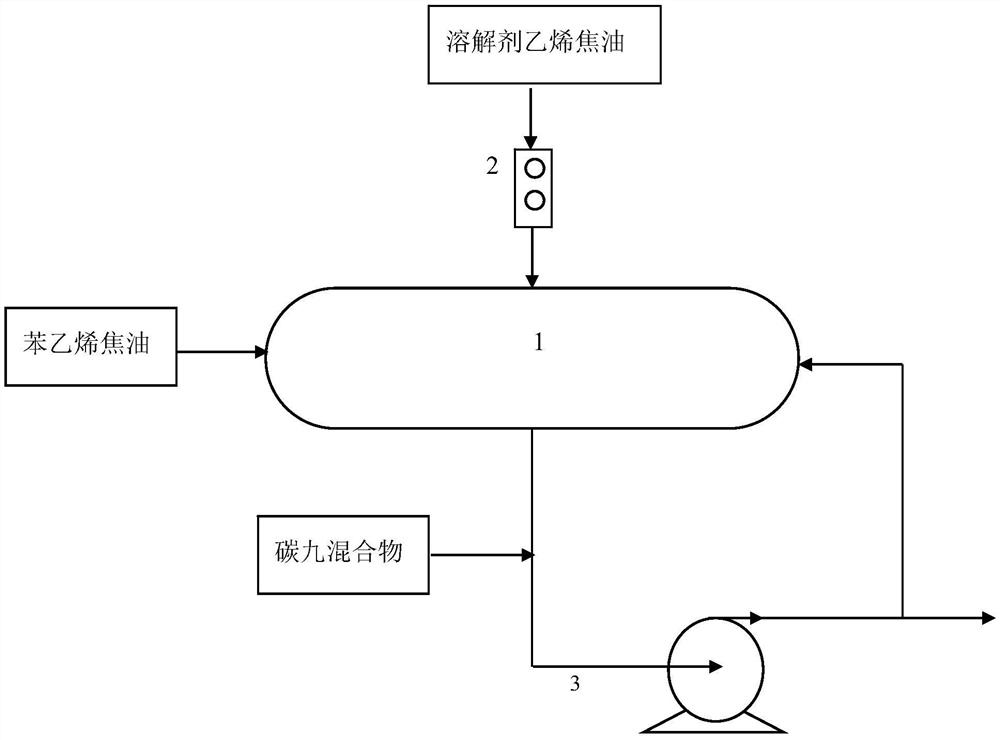

Image

Examples

Embodiment 1

[0030] A method for reducing the viscosity of styrene tar and improving fluidity, comprising the following steps:

[0031] (1) Pre-filling: Before the styrene tar is transported into the styrene tar tank, the carbon 9 mixture with a temperature of about 55°C is filled with the tank bottom line of the styrene tar tank, and the tank of the styrene tar tank is filled with Put a layer of carbon-9 mixture on the bottom pad, and open the condensate outlet at the bottom of the tank to have liquid;

[0032] (2) Heating: after the completion of step (1), the styrene tar and the dissolving agent ethylene tar are transported into the styrene tar tank together. position), immediately start the electric heater to heat the liquid in the styrene tar tank, and the temperature is controlled at about 58 °C;

[0033] (3) Mixing: in the process of transporting styrene tar into the styrene tar tank, the dissolving agent ethylene tar is also transported into the styrene tar tank, so that the two a...

Embodiment 2

[0037] A method for reducing the viscosity of styrene tar and improving fluidity, the operation method is basically the same as that in Example 1, except that in step (3), the mass ratio of dissolving agent ethylene tar and styrene tar is 3:1; After the implementation of this plan, there was no blockage or agglomeration on the transportation pipeline within 12 months of transportation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com