A kind of Bacillus amyloliquefaciens culture, preparation method and application thereof

A technology of amylolytic spores and cultures, which is applied in the field of animal feed additive preparation, and can solve problems such as unsuitable feeding in summer, reducing the conception rate of sows, and affecting the normal development of pigs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] A preparation method of bacillus amyloliquefaciens culture, is characterized in that, comprises the steps:

[0044] (1) Preparation of solid-state fermentation base material: pretreated white distiller's grains powder is the main fermentation base material, puffed corn flour is used as carbon source, diamine hydrogen phosphate is used as nitrogen source, and calcium carbonate is used as acidity regulator; wherein the added amount of puffed corn flour is 5-15% (w / w pretreated distiller's grain powder); the addition of diammonium phosphate is 5% (w / w pre-treated distiller's grain powder); the addition of calcium carbonate is 1.5-2.0% (w / w pretreatment distiller's grains powder);

[0045] (2) Preparation of Bacillus amyloliquefaciens seed solution: activating Bacillus amyloliquefaciens with a liquid medium, subcultured to make a seed solution;

[0046] (3) Fermentation: Inoculate the seed solution prepared in (2) into the solid-state fermentation base material in (1), the...

Embodiment 1

[0059] Take 5 kg of fresh distiller's grains, add 15% (w / w distiller's grains) puffed corn flour, 0.5% (w / w distiller's grains) diammonium hydrogen phosphate, and replenish water to prepare a fermentation base material. Spread the fermentation base material in the fermentation workshop, with a stacking thickness of 15cm, adjust the temperature of the fermentation workshop, and raise the temperature of the base material to 35±0.2°C. The activated bacillus amyloliquefaciens is diluted and evenly sprayed on the surface of the fermentation base material according to the inoculation amount of 1% (w / v). During the first 12 hours of the fermentation process, the material was turned every 4 hours, and after 12 hours of fermentation, the material was turned every 2 hours. During the fermentation process, samples were taken every 6 hours to determine the pH. The total fermentation time is 72 hours. After the fermentation is over, the number of viable bacteria of Bacillus amyloliquefacie...

Embodiment 2

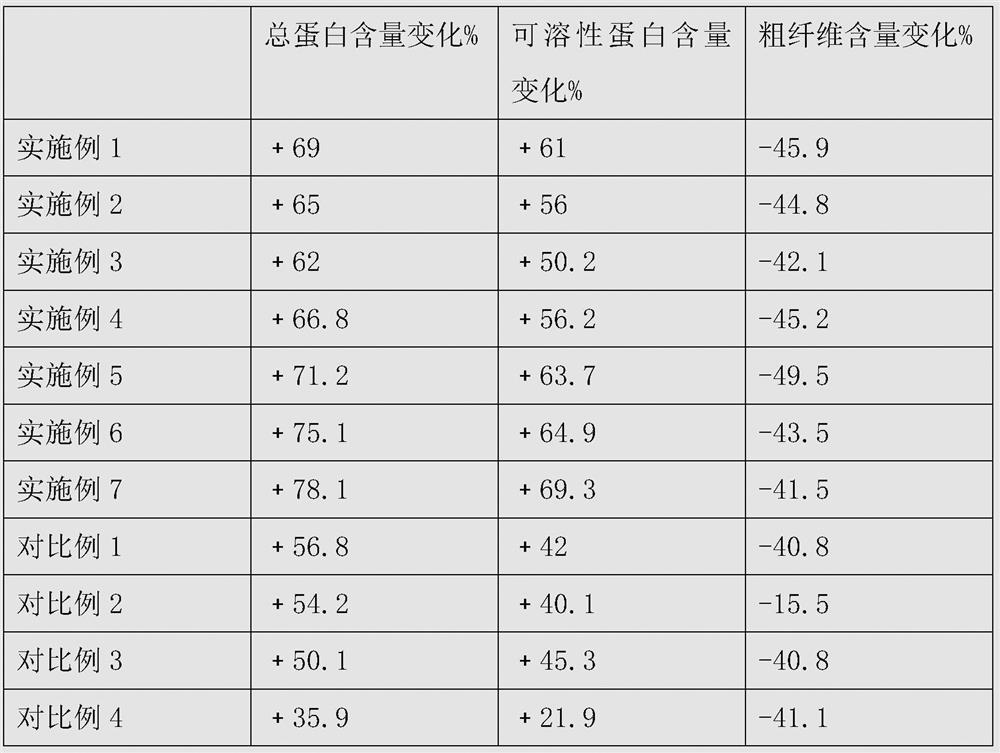

[0067] The difference between this embodiment and embodiment 1 is only that 8% (w / w distiller's grains) puffed corn flour is added, and the rest of the steps and parameters are the same as in embodiment 1. After the fermentation, the number of live bacteria of Bacillus amyloliquefaciens can reach 18.1 billion / g by dilution coating plate method. The fermented culture is dried, pulverized, and passed through a 100-mesh sieve. Measure and calculate the crude protein content, soluble protein content and the change rate of crude fiber, and include them in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com