Saturated resin hydrochloric acid protonation transformation water leaching process

A hydrochloric acid proton and resin technology, which is applied in the field of rinsing technology, can solve the problems of difficult control of adsorption tail liquid, resin poisoning, and high run-off of adsorption tail liquid, and achieve the effects of underground leaching, high product quality and low adsorption tail liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

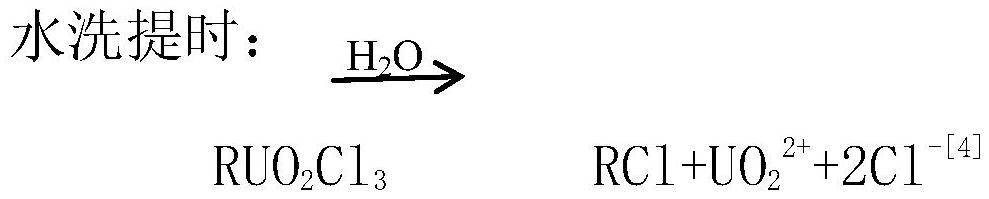

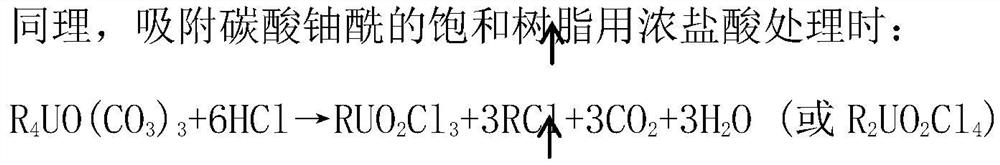

[0016] The present invention will be described in further detail below in conjunction with specific embodiments.

[0017] A kind of saturated resin hydrochloric acid protonation transition water rinsing process, comprises the steps:

[0018] (1) Select a high-efficiency leaching agent (such as clear water) to improve the leaching efficiency, reduce the concentration of uranium in the adsorption tail liquid, and prevent the occurrence of resin poisoning and tower blockage;

[0019] (2) Select a suitable eluting agent (such as clear water) to reduce the impurity content in the qualified liquid and improve product quality;

[0020] (3) Adopt appropriate rinsing process to reduce HCO in ground immersion solution 3 _ consumption.

[0021] The 738 factory selected in this example is located in a desert area, and there is a shortage of clean water. If the resin hydrochloric acid is protonated, a large amount of water will be needed for flushing. If it is directly returned to adsor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com