A kind of strongly stable light-limiting five-member polyelement nanoparticle and its preparation method

A nanoparticle and optical limiting technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the limitations of the production field of polyelement nanoparticles, the stability of polyelement nanoparticles is not strong, Problems such as complex pyrolysis and loading process, etc., achieve the effect of overcoming the limitation of solid solubility, high synthesis efficiency, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A strongly stable light-limiting five-member polyelement nanoparticle and a preparation method thereof. Described preparation method is:

[0044] The component expression of the strongly stable light-limiting five-element polyelement nanoparticle is CuXNiFeZn; wherein: X represents cobalt.

[0045] The steps of the preparation method described in this embodiment are:

[0046] Step 1. According to the mass ratio of copper:cobalt:nickel:iron:zinc: 63.5:58.9:58.7:55.8:65.4, the metallurgical raw material is obtained.

[0047] The purity of any component in the metallurgical raw material is ≥99.9%.

[0048] Step 2: Use sandpaper and a grinder to remove the oxide layer on the surface of the metallurgical raw material, then use industrial ethanol to ultrasonically vibrate and clean it, and dry it to obtain the target material raw material.

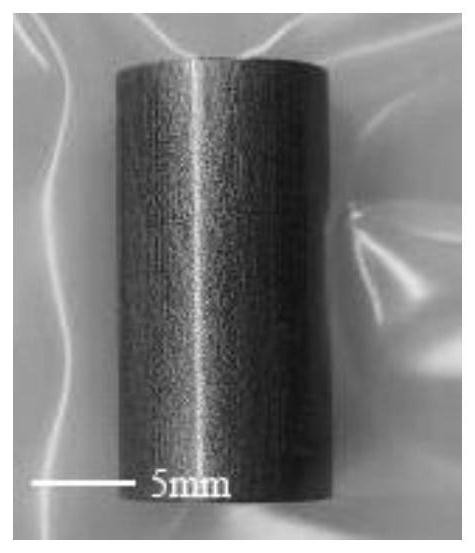

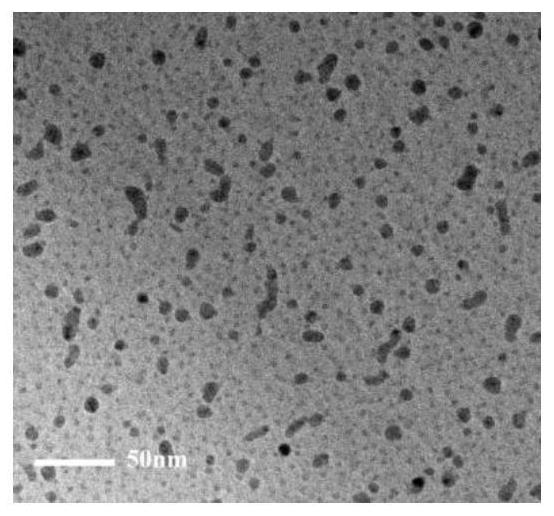

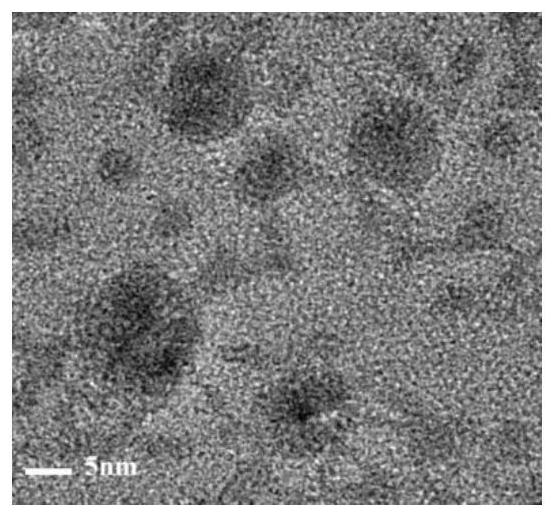

[0049] Step 3, the target raw material is prepared by metallurgical method such as figure 1 The photo of the CuCoNiFeZn five-element...

Embodiment 2

[0057] A strongly stable light-limiting five-member polyelement nanoparticle and a preparation method thereof. Described preparation method is:

[0058] The composition expression of the strongly stable light-limiting five-element polyelement nanoparticle is CuXNiFeZn; wherein: X represents molybdenum.

[0059] The steps of the preparation method described in this embodiment are:

[0060] Step 1. According to the mass ratio of copper:molybdenum:nickel:iron:zinc: 63.5:96.0:58.7:55.8:65.4, the metallurgical raw material is obtained.

[0061] The purity of any component in the metallurgical raw material is ≥99.9%.

[0062] Step 2: Use sandpaper and a grinder to remove the oxide layer on the surface of the metallurgical raw material, then use industrial ethanol to ultrasonically vibrate and clean it, and dry it to obtain the target material raw material.

[0063] Step 3: The target raw material is prepared by metallurgical method to obtain a CuMoNiFeZn five-element high-entropy...

Embodiment 3

[0068] A strongly stable light-limiting five-member polyelement nanoparticle and a preparation method thereof. Described preparation method is:

[0069] The composition expression of the strongly stable light-limiting five-element polyelement nanoparticle is CuXNiFeZn; wherein: X represents aluminum.

[0070] The steps of the preparation method described in this embodiment are:

[0071] Step 1. According to the mass ratio of copper:aluminum:nickel:iron:zinc: 63.5:27.0:58.7:55.8:65.4, the metallurgical raw material is obtained.

[0072] The purity of any component in the metallurgical raw material is ≥99.9%.

[0073] Step 2: Use sandpaper and a grinder to remove the oxide layer on the surface of the metallurgical raw material, then use industrial ethanol to ultrasonically vibrate and clean it, and dry it to obtain the target material raw material.

[0074]Step 3, using the target raw material to produce a CuAlNiFeZn five-element high-entropy alloy material by a metallurgical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com