Water tank water feeding automatic control and oscillation anti-freezing device and method

A technology of antifreeze device and control method, which is applied in the direction of non-electric variable control, control/regulation system, and simultaneous control of multiple variables, etc., which can solve problems such as high labor intensity, increased investment cost, and limited inspection intensity, and achieve easy relocation Transportation, high degree of automation, and the effect of improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the above and other objects, features and advantages of the present invention more comprehensible, the preferred embodiments are listed below and shown in the accompanying drawings in detail as follows.

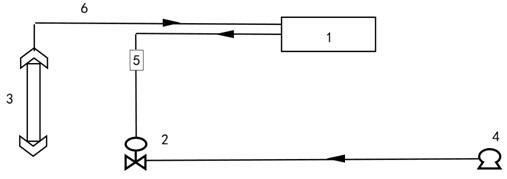

[0028] Such as figure 1 as shown, figure 1 It is a structural diagram of the water tank automatic control and vibration antifreeze device of the present invention. The water tank automatic control and vibration antifreeze device includes a PLC control system 1, an electric regulating valve 2, an electronic liquid level gauge 3, a pipeline booster pump 4, a control circuit 5, and a signal line 6.

[0029] Among them, the control circuit 5 is connected with the PLC control system 1 and the electric regulating valve 2, and is used to control the signal (4mA~20Ma or 0V~20V or depending on the electric regulating valve used) sent by the PLC control system 1 for controlling the working state of the electric regulating valve 2 2 control signal requirements)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com