Three-dimensional laser scanner for engineering surveying

A three-dimensional laser and engineering measurement technology, applied in the direction of measuring devices, optical devices, radio wave measurement systems, etc., can solve the problems of long time consumption and low scanning efficiency, improve accuracy, save scanning time, and improve scanning efficiency speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

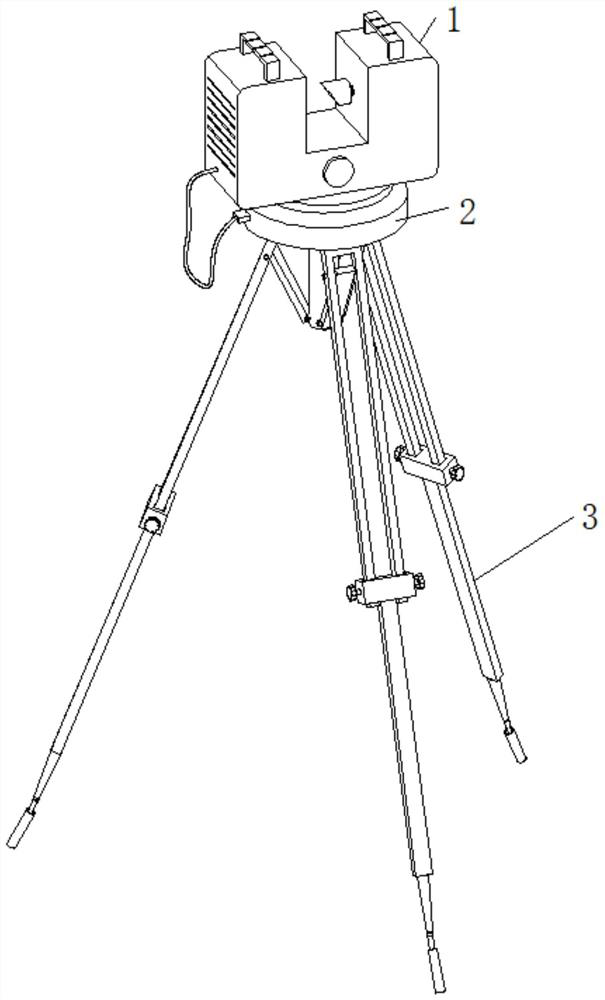

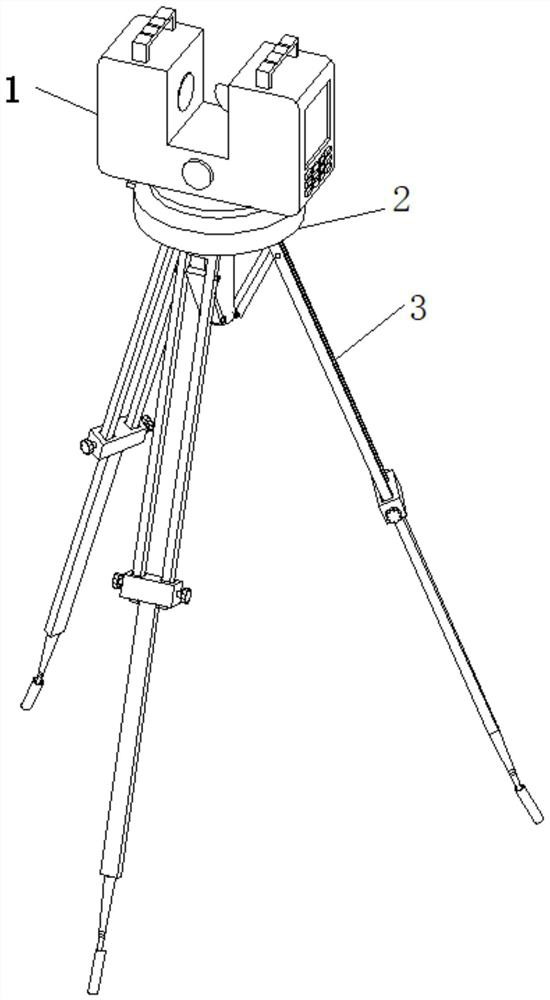

[0029] see Figure 1-6 , an embodiment provided by the present invention: a three-dimensional laser scanner for engineering survey, comprising a three-dimensional laser scanner body 1, a base 2, a tripod 3 and a lithium battery 4, the three-dimensional laser scanner body 1 is rotatably mounted on the base 2. The upper end and the bottom end of the base 2 are fixedly equipped with a tripod 3, and the three-dimensional laser scanner body 1 is powered by a lithium battery 4;

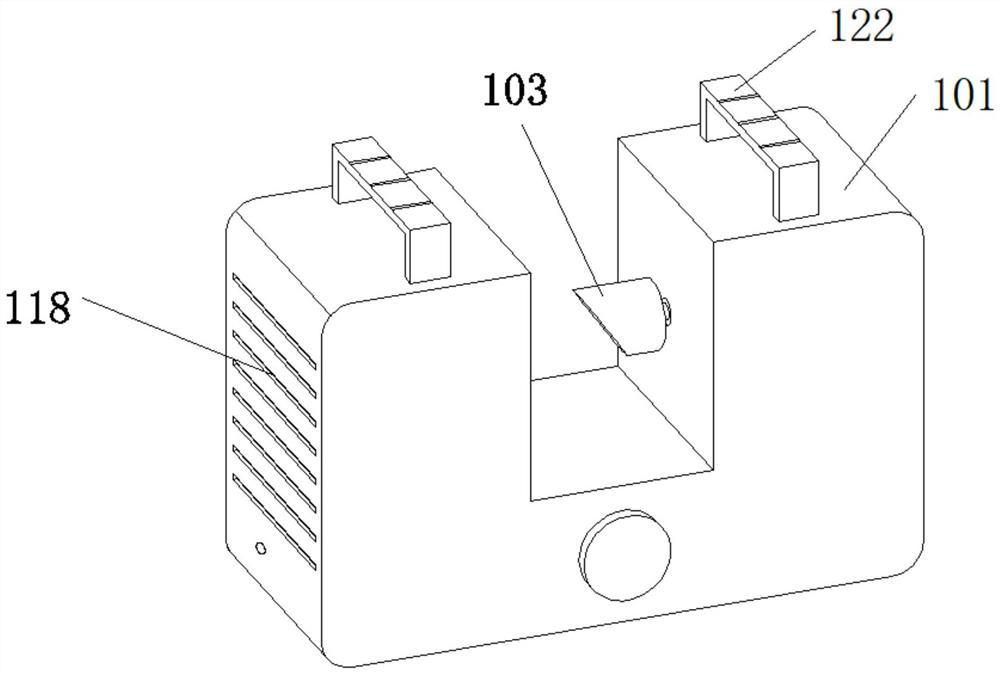

[0030]The three-dimensional laser scanner body 1 includes a casing 101, a laser radar 102, a filter mirror 103, a first speed sensor 104, a first motor 105, a panoramic camera 106, a time counter 107 and a central processing unit 108; The mirror 103 is facing to the left and right, and the right side wall of the optical filter 103 is fixed with a rotating shaft 109, and the right end of the rotating shaft 109 is fixed with a transmission wheel 110, and the left side wall of the transmission wheel 110 is pro...

Embodiment 2

[0036] On the basis of Example 1, such as figure 1 and Figure 10 As shown, a glass vial 209 is embedded on the upper surface of the base 2, and the accuracy of the glass vial 209 is 30', which can rotate around the axis to maintain accuracy.

[0037] During implementation of this embodiment, the setting of the glass vial 209 is convenient for judging whether the three-dimensional laser scanner is in a horizontal state, which can effectively reduce the error of the scanning result, and the cost of the glass vial 209 is low.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com