Archimedes helicoid worm gear hobbing and shaving precision detection method

A technology of Archimedes spiral and processing precision, applied in the direction of measuring device, belt/chain/gear, hoisting device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0084] The present invention will be further described below in conjunction with the accompanying drawings and specific examples to better understand the invention and can be implemented, but the exemplary embodiments are not limited to the present invention.

[0085] In this embodiment, the Aqui-screw surface worm wheel roll shaver, including the following steps:

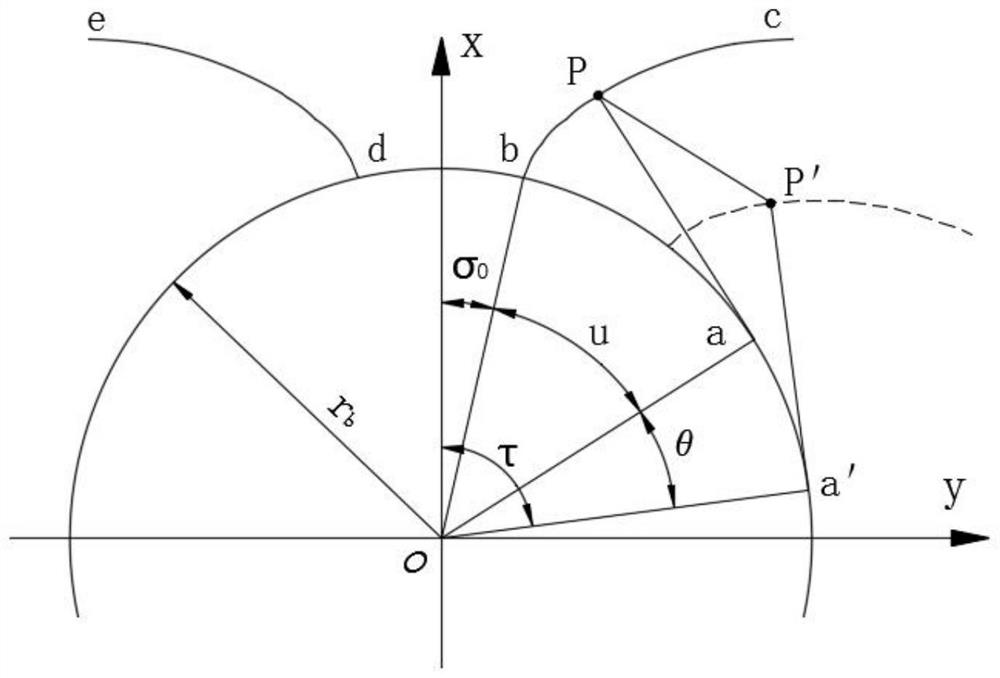

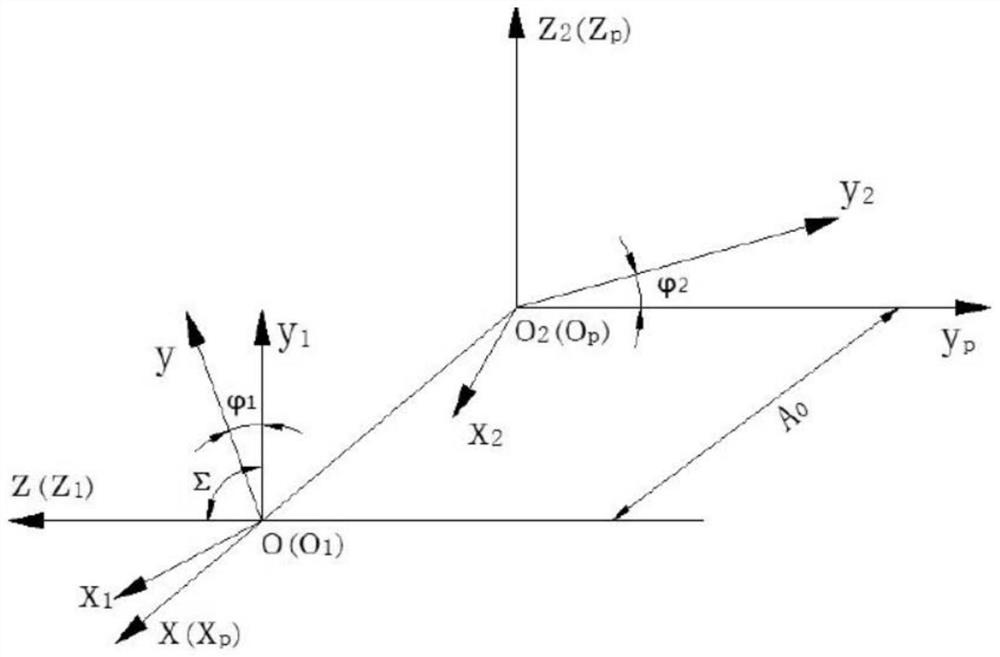

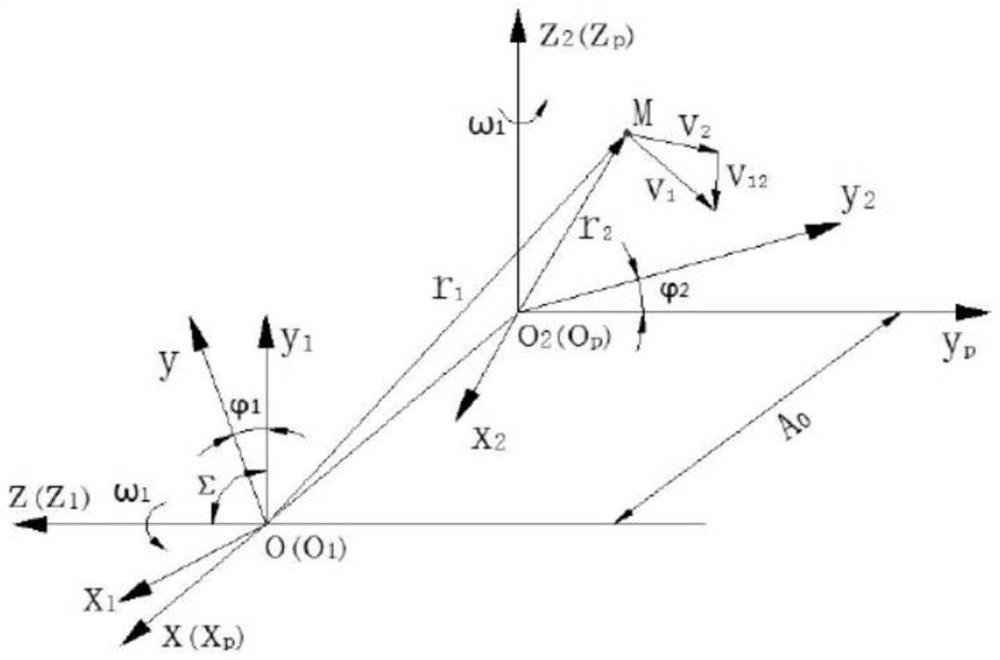

[0086] 1) Construction of the tooth surface equation and the tooth surface method of the Aqui moles according to the spiral surface of the Aqui moles.

[0087] According to the type of worm, the number of worms head 1 , Worm gear number, modulus M, toothed pressure angle α, worm index circular diameter D 1 , Spiral rising angle γ, teeth B, pitch, transmission ratio I 21 Center distance 0 , Tooth top circular diameter D a1 , Root a diameter D f1 Determine the spiral surface of the Aqui moles and the axis, specific:

[0088] The spiral surface of the Akimid worm is adjacent:

[0089]

[0090] The spiral surface axis of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com