Sample for testing dynamic tensile property of titanium alloy subjected to adiabatic shearing

A dynamic stretching and adiabatic shearing technology, which is used in the preparation of test samples, the application of stable tension/pressure to test the strength of materials, and the sampling, etc., to prevent additional damage caused by large loads and eliminate interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0035] The invention provides a sample used for testing the dynamic tensile performance of titanium alloy after adiabatic shearing. Specifically, as a specific embodiment of the present invention, the preparation process of a sample for testing the dynamic tensile properties of a titanium alloy after adiabatic shearing includes the following steps:

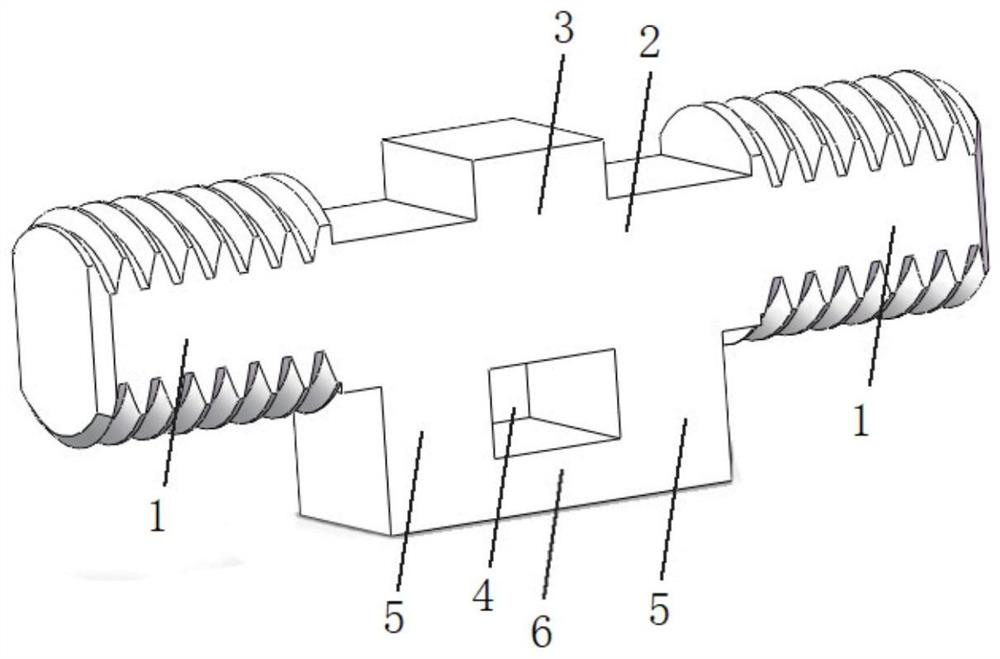

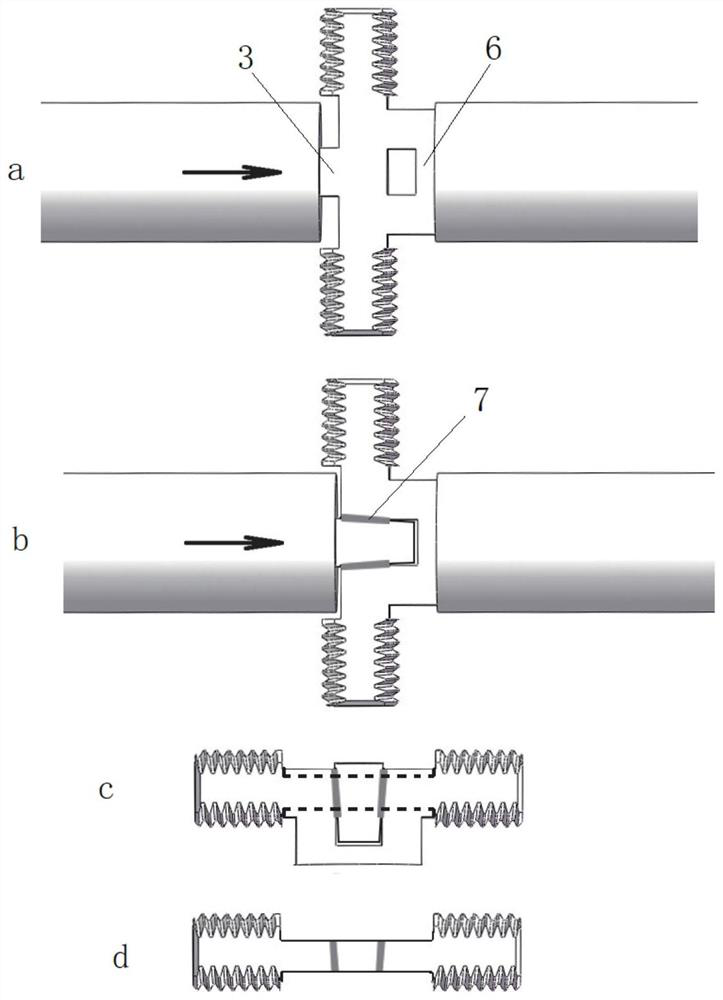

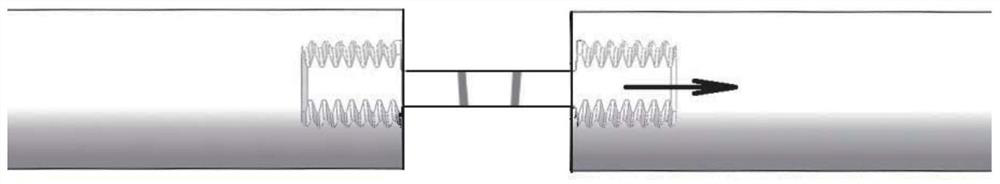

[0036] (1) Process the sample blank into such as figure 1 structure shown. Specifically, the two ends of the sample blank are processed into a half-thread shape as the supporting end 1, and the boss 3 to be impacted is processed on one side of the parallel working section 2 between the two supporting ends 1; A through hole 4 is processed on the top, and the shape of the boss 3 to be impacted and the shape of the rectangular through hole 4 can be selected according to needs. For example, a rectang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com