Area array industrial CT scattering correction method

A technique for scatter correction and beam hardening correction, which is used in material analysis, instruments, and measurement devices using wave/particle radiation. The effect of simplicity and few algorithm steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

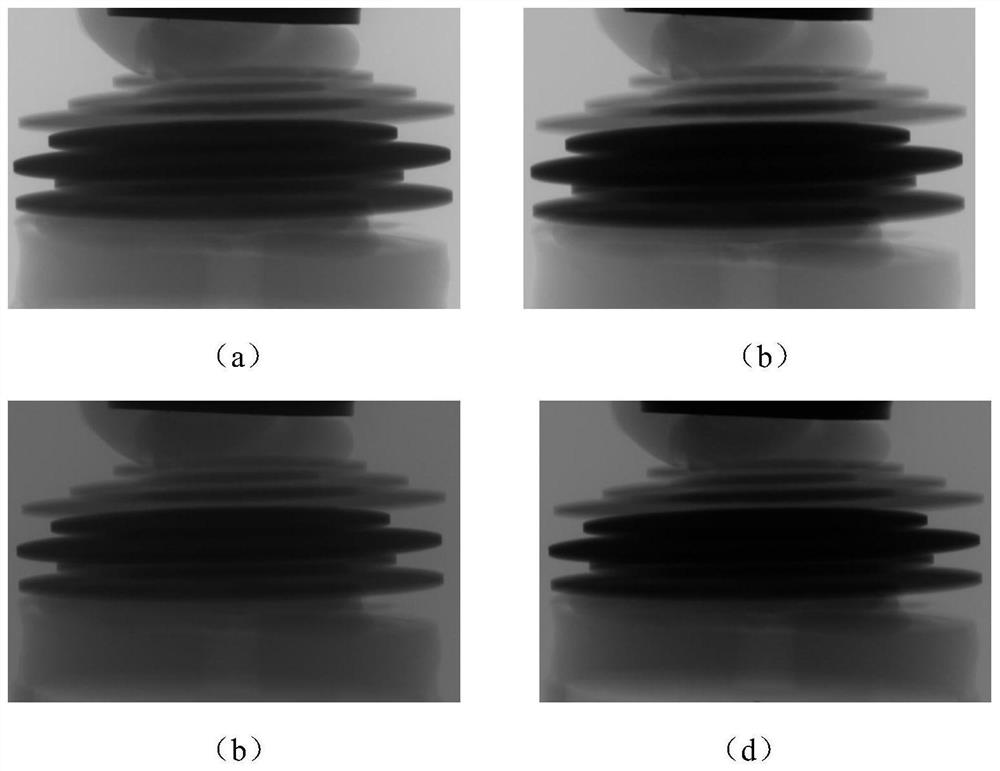

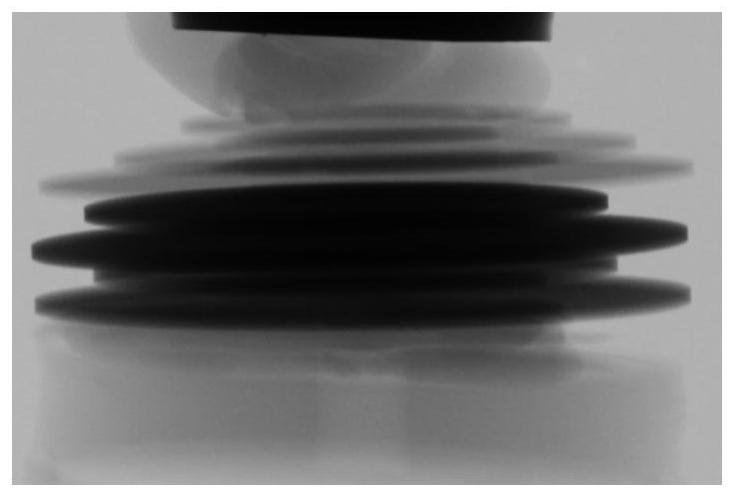

[0054] An area array industrial CT scattering correction method, comprising the following steps:

[0055] Step 1. Use an X-ray machine to perform circumferential DR scanning on the tested sample, obtain a first circumferential DR image of the tested sample, and perform beam hardening correction on the first circumferential DR image of the tested sample , to obtain I first images; wherein, the pixel of (x, y) in the i-th first image is denoted as A i (x, y), i=1, 2...I;

[0056] In this embodiment, the beam hardening correction method used in step 1 and step 2 is a stepped test block or a Monte Carlo statistical simulation method, and these beam hardening correction methods are existing methods; of course, other existing methods can also be used beam hardening correction method;

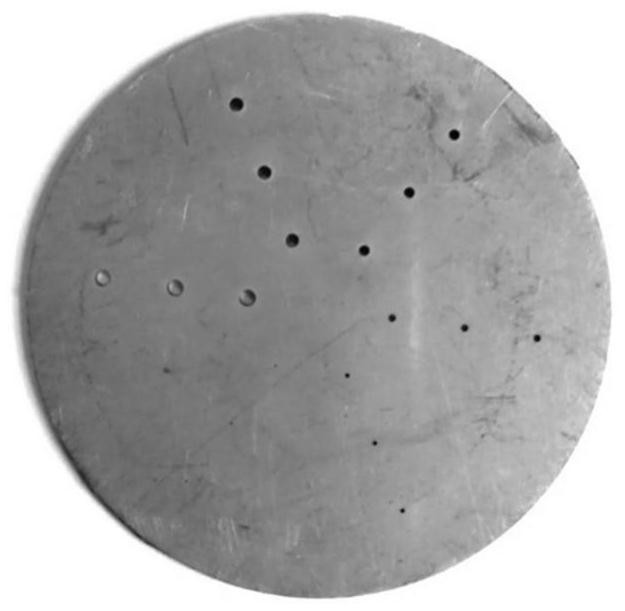

[0057] Step 2. Place an attenuation plate with a thickness of S in front of the beam output window of the X-ray machine. The material used for the attenuation plate corresponds to an attenuation coe...

Embodiment 2

[0105] Different from Embodiment 1, the beam hardening correction method used in Embodiment 2 includes the following steps:

[0106] Step a, processing N filters with different penetration thicknesses; wherein, the penetration thickness of each filter is less than or equal to the maximum penetration thickness of the tested sample; N is a positive integer;

[0107] Step b, place each filter in stages before the beam output window of the X-ray machine, and use the same scanning process to perform DR scanning on each filter to obtain the DR image of each filter; the DR image of each filter The dimensions are all c×d; wherein, the scanning process in this embodiment includes at least the parameters of tube voltage, tube current, magnification ratio, focus size and integration time; these parameters are all process parameters used when the X-ray machine performs DR scanning;

[0108] Step c, perform exponential fitting according to the gray value of the DR image of the filter in st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap