Micro-LED chip structure and preparation method

A chip structure and chip technology, applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve the problems of low yield rate and difficult mass transfer technology, and achieve the effect of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

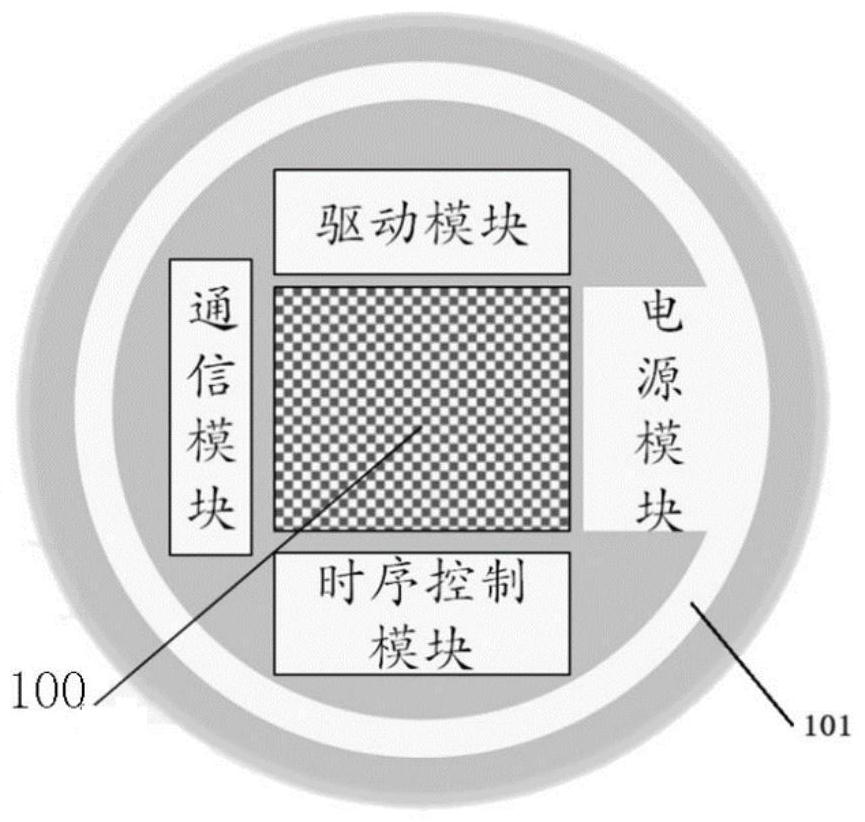

[0027] A Micro-LED chip structure of the present invention, such as figure 1 As shown, the shape of the Micro-LED chip of the present invention includes but is not limited to a circle, including a Miro-LED light-emitting dot matrix 100, a driving module, a power module, a communication module and a timing control module.

[0028] The driving module is connected to each light-emitting point in the Micro-LED light-emitting dot matrix 100 through a signal line, and is used to provide driving signals to the Micro-LED light-emitting dot matrix 100 through various signal sources such as voltage and current. The driving module includes a source driver circuit, gate drive circuit, and external compensation circuit, etc.

[0029] The timing control module is connected with the driving module for providing clock signals and coordinating the timing coordination of each circuit in the driving module.

[0030] The communication module is connected with the drive module, and is used to tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com