Harmless treatment device for public hazard sanding dust of plywood and treatment method

A harmless treatment, plywood technology, applied in grinding/polishing safety devices, surface-polished machine tools, grinding/polishing equipment, etc., can solve the pollution sanding dust environment and equipment hazards, reduce the service life of hot oil furnace , enterprise economic losses and other issues, to achieve the effect of harmless treatment, important economic and environmental significance, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

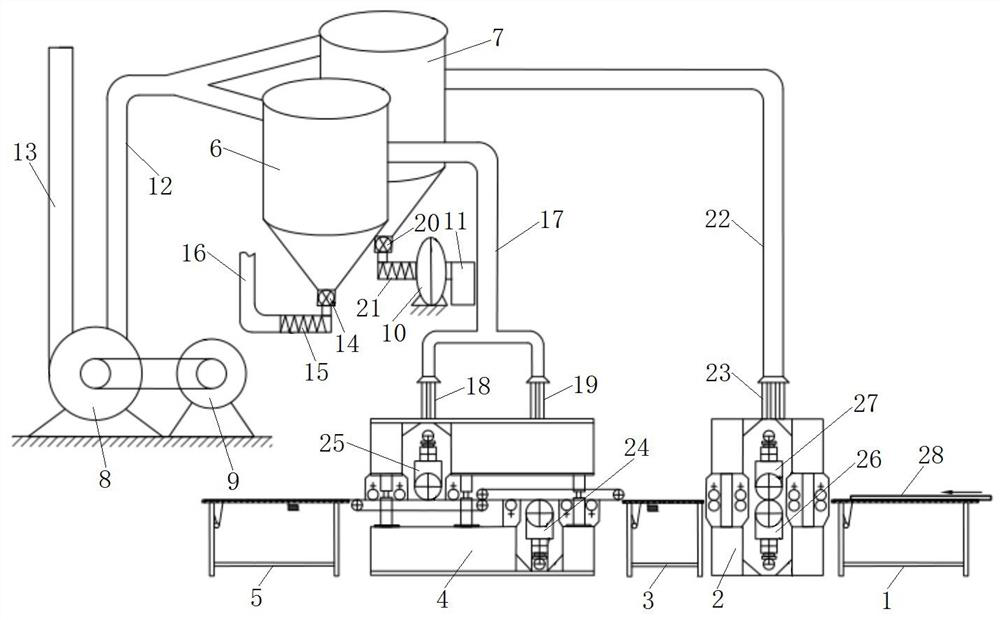

[0025] Such as figure 1 As shown, a plywood has a pollution-free sanding dust harmless treatment device, which is mainly composed of a differential sanding system and a sanding dust recovery system; the differential sanding system is mainly composed of an opposed double-sided sanding machine 2 and The offset type double-sided sander 4 is composed of; the front end of the opposed type double-sided sander 2 is provided with a pallet 1, and the rear end of the offset type double-sided sander 4 is provided with a pallet 5. A transfer table 3 is arranged between the set type double-sided sander 2 and the offset type double-sided sander 4; the sanding dust distinction recovery system is mainly composed of a wood dust collector 6, a putty dust collector 7, and a grinder. 10, baler 11, negative pressure blower 8 and motor 9 are made up; The air suction port of described negative pressure blower 8 is connected with wood dust collector 6, putty dust collector 7 respectively; Described w...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap