Dry garbage collection system and method with compressing and packaging functions

A technology for garbage collection and garbage, which is applied in garbage collection, trash cans, household appliances, etc., to achieve the effect of ingenious structure, reduced manufacturing cost, and small device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

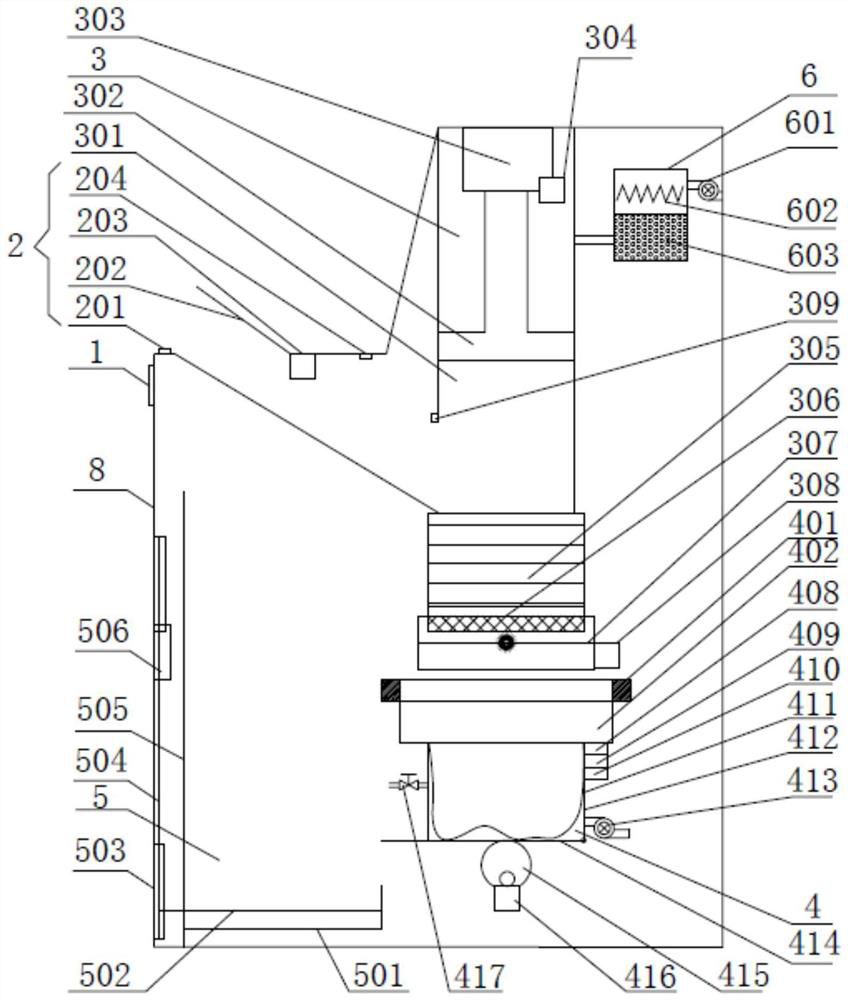

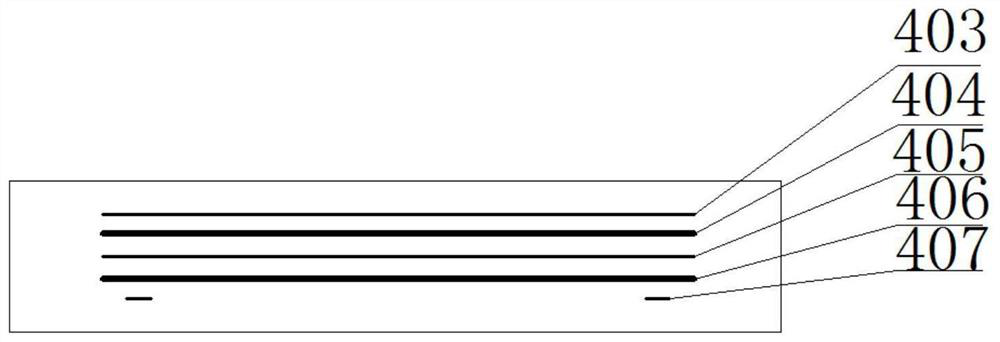

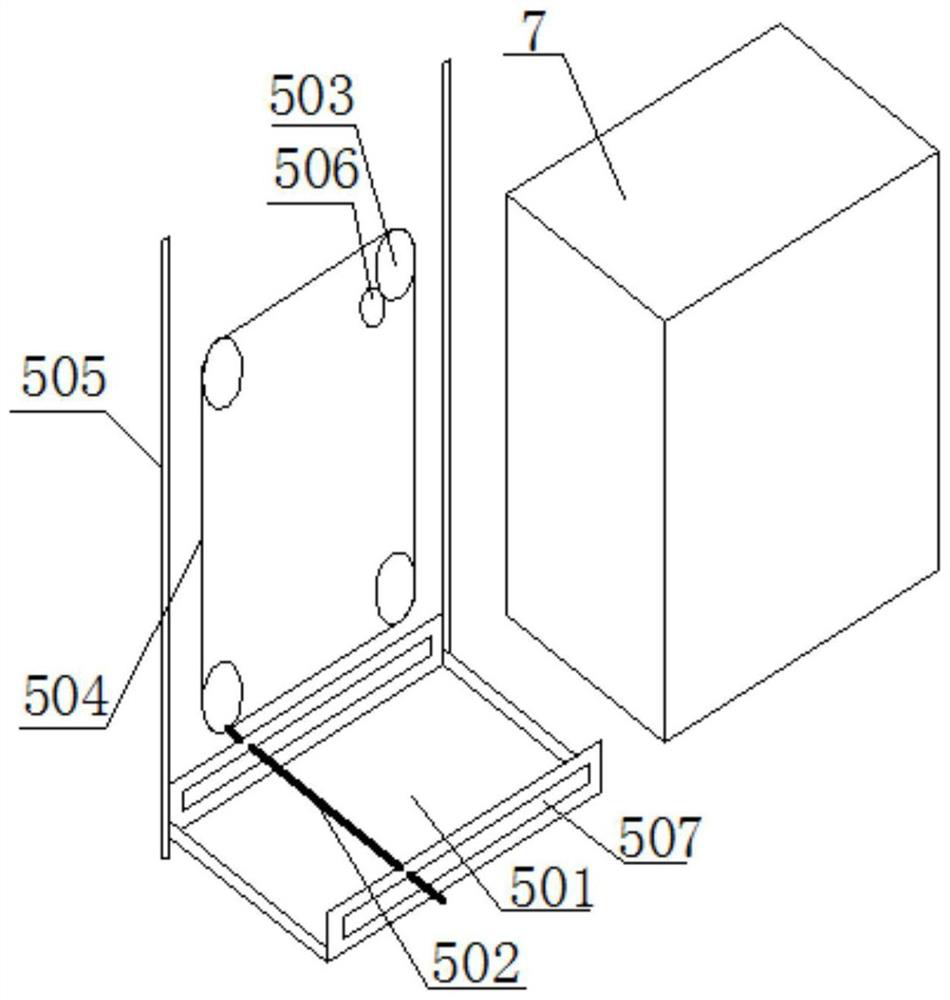

[0064] refer to Figure 1~4 , a dry garbage collection system with compression and packaging functions, including: a box body 8 and a central control display 1 set in it, a garbage disposal bin 2, a compression hot-melt bin 3, a packing bin 4, a transfer bin 5, and an air purification bin 6 , trash can 7;

[0065] The garbage delivery bin 2 is located at the front end of the entire collection system, the compressed hot-melt bin 3 is connected to the garbage bin 2, the upper entrance of the packing bin 4 is connected to the lower outlet of the compressed hot-melt bin 3, and the transfer bin 5 communicates with the packaging bin 4, the trash bin 7 is located below the upper outlet of the transfer bin 5, the air purification bin 6 is located in the box body 8 and communicates with the compression hot-melt bin 3, and the central control display 1 is installed in the box body 8 superior.

[0066] The garbage disposal bin 2 comprises: a No. 1 infrared sensor 201, an induction rota...

Embodiment 2

[0073] This embodiment is applied to the dry garbage collection system with the function of compressing and packaging in Embodiment 1.

[0074] A method of dry garbage collection with compression and packaging, comprising the following steps:

[0075] Step A, Trash Disposal

[0076] When the No. 1 infrared sensor is triggered, record the weight of the garbage in the compression hot-melt bin 3 at this time, and record it as G0;

[0077] Open the induction rotating cover 202, and close it after the set time t;

[0078] Step B, waste weighing

[0079] When the No. 2 infrared sensor is triggered, add 1 to the count of the input garbage bag;

[0080] Record the weight of the rubbish in the compression hot melt bin 3 at this time, denoted as G1;

[0081] Step C, garbage compaction

[0082] Control the hydraulic device to compress the rubbish through the central control display 1;

[0083] Step D, the garbage is weighed again

[0084] Weigh the compressed garbage located in th...

Embodiment 3

[0103] Turn on the power, start the central control display 1, trigger the No. 1 infrared sensor 201 with hands or objects, and after the No. 1 infrared sensor 201 receives the signal, record the weight of the garbage in the central control display 1 as G0, and control No. 1 at the same time The motor 203 opens the induction rotating cover 202 and lasts for 5 seconds, at this time, the garbage is thrown into the garbage bin 2 .

[0104] During the process of garbage entering the hydraulic bin 301, the No. 2 infrared sensor 204 in the garbage bin 2 senses that the garbage has passed and sends a signal to the central control display 1, and the central control display 1 counts up by 1, and reads the display of the electronic scale 306 And record it as G1.

[0105] Start the No. 2 motor 304, and the No. 2 motor 304 controls the compression plate 302 to reciprocate by controlling the hydraulic cylinder 303. After one compression is completed, the central control display 1 reads the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com