Preparation method of reinforced concrete for emergency water conservancy project

A reinforced concrete and water conservancy engineering technology, applied in the field of reinforced concrete, can solve the problems of poor solidification effect of reinforced concrete and ineffective effect of reinforced concrete, and achieve the goal of reducing unit water consumption, good solidification effect and promoting early strength The effect of development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

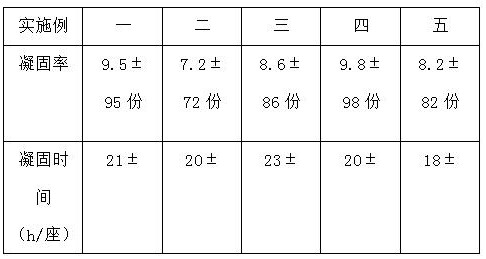

Examples

Embodiment 1

[0026] The invention proposes a method for preparing reinforced concrete for emergency water conservancy projects, comprising the following raw materials in parts by weight: 25 parts of water, 22 parts of cement, 11 parts of gel material, 13 parts of aggregate, 6 parts of foaming agent, and 14 parts of sand , 8 parts of accelerator, 5 parts of polypropylene fiber, 6 parts of water reducing agent, 5 parts of early strength agent.

[0027] Its preparation method is as follows: first, water, cement, gel material, aggregate, foaming agent, sand are added in the mixer and stirred at a speed of 15 revolutions per minute for 13 minutes to obtain the first mixture, and then the speed Add coagulant, polypropylene fiber, water reducer, and early strength agent into the mixer according to the proportion and stir at a speed of 15 rpm for 5 minutes to obtain the second mixture, and mix the first mixture with the second mixture at the same time , to obtain highly efficient solidified emerge...

Embodiment 2

[0029] The invention proposes a method for preparing reinforced concrete for emergency water conservancy projects, comprising the following raw materials in parts by weight: 25 parts of water, 25 parts of cement, 10 parts of gel material, 10 parts of aggregate, 5 parts of foaming agent, and 15 parts of sand , 8 parts of accelerator, 6 parts of polypropylene fiber, 5 parts of water reducing agent, 7 parts of early strength agent.

[0030] Its preparation method is as follows: first, water, cement, gel material, aggregate, foaming agent, sand are added in the mixer and stirred at a speed of 16 revolutions per minute for 11 minutes to obtain the first mixture, and then the speed Add the coagulant, polypropylene fiber, water reducer, and early strength agent into the mixer according to the proportion and stir at a speed of 16 rpm for 8 minutes to obtain the second mixture, and mix the first mixture with the second mixture at the same time , to obtain highly efficient solidified em...

Embodiment 3

[0032] The invention proposes a method for preparing reinforced concrete for emergency water conservancy projects, comprising the following raw materials in parts by weight: 33 parts of water, 25 parts of cement, 12 parts of gel material, 11 parts of aggregate, 5 parts of foaming agent, and 20 parts of sand , Accelerator 10 parts, polypropylene fiber 10 parts, water reducing agent 2 parts, early strength agent 5 parts.

[0033] Its preparation method is as follows: first, water, cement, gel material, aggregate, foaming agent, and sand are added into the mixer and stirred at a speed of 18 revolutions per minute for 15 minutes to obtain the first mixture, and then the speed Add the coagulant, polypropylene fiber, water reducer, and early strength agent into the mixer according to the proportion and stir for 9 minutes at a speed of 18 rpm to obtain the second mixture, and mix the first mixture with the second mixture at the same time , to obtain highly efficient solidified emerge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com